Thermal equilibrium type bipolar cell stack

A bipolar battery and thermal equalization technology, which is applied in bipolar electrodes, secondary batteries, secondary battery manufacturing, etc., can solve the problems that battery cells cannot be dissipated as soon as possible, shorten the life of the battery stack, and reduce the performance of the battery stack. Achieve simple and flexible structure, maintain consistency, and improve battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, the present invention will be further described through embodiments with reference to the accompanying drawings.

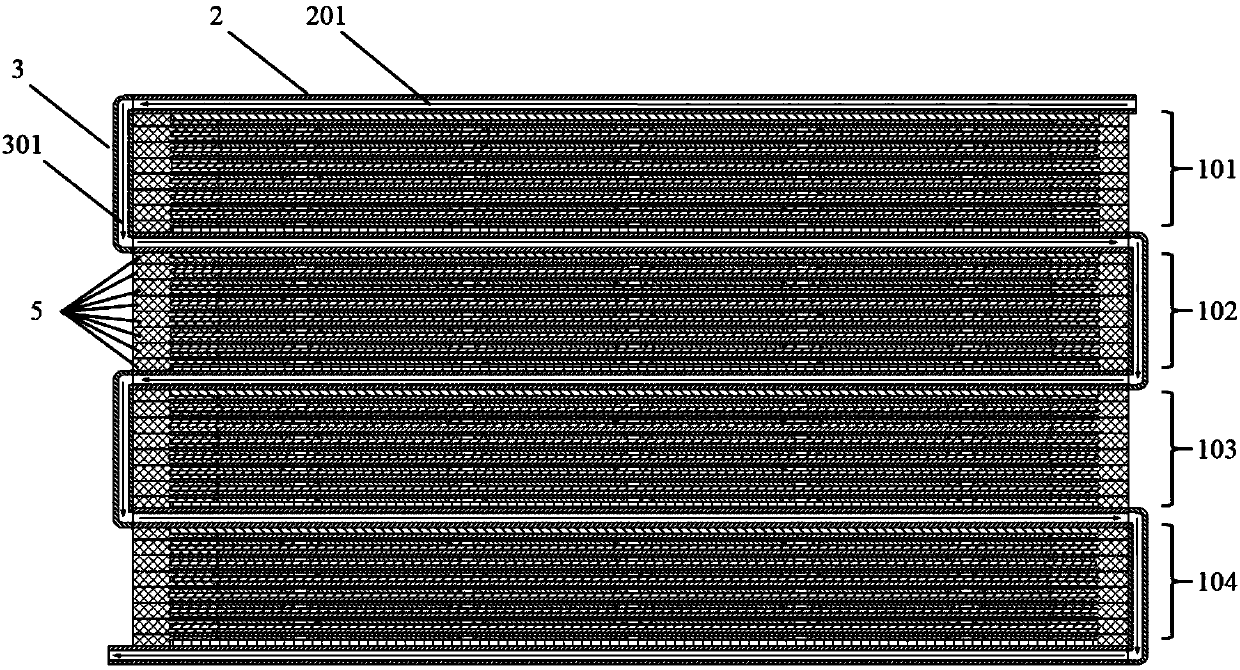

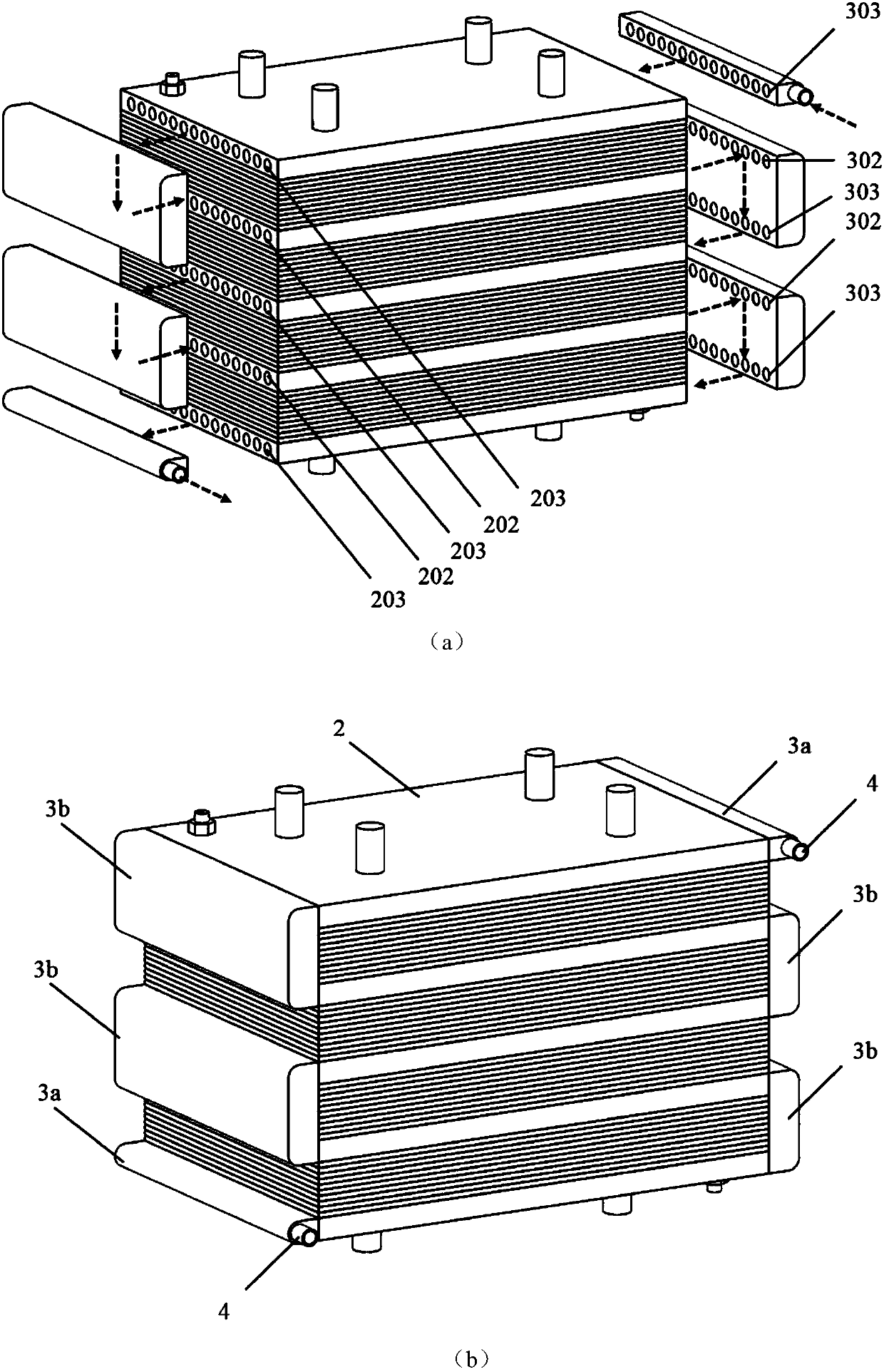

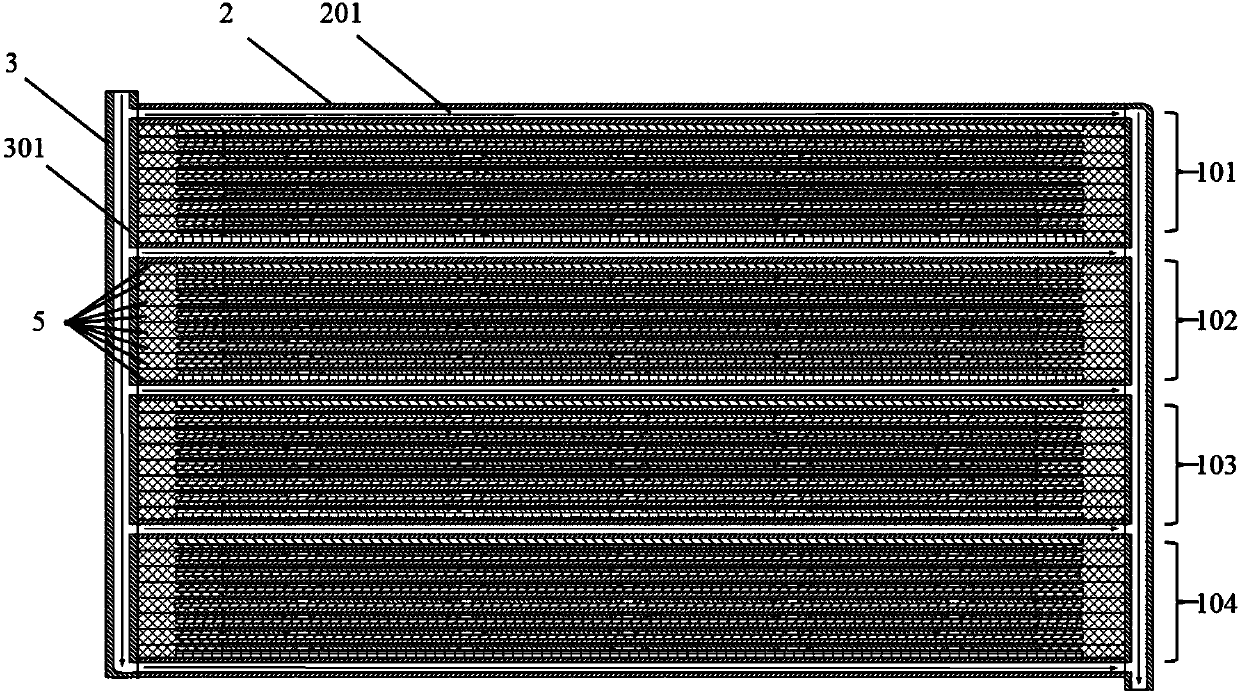

[0041] figure 1 It is a schematic cross-sectional view of a thermally balanced bipolar battery stack according to the first embodiment of the present invention. figure 1 The illustrated thermally balanced bipolar battery stack includes four sets of electrode sheets 101, 102, 103, 104 and a series-type thermal balance device. Each group of electrode plates includes a plurality of bipolar electrode plates and unipolar electrode plates arranged on the upper and lower sides of the entire plurality of bipolar electrode plates. The thermal equalization device includes a first baffle 2 and a second baffle 3. A first channel 201 is provided in the first baffle 2 and a second channel 301 is provided in the second baffle 3. The five first baffles 2 are respectively arranged on the upper side of the first group of electrode sheets 101 from the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com