Air suction type precision seeding apparatus for peanuts

A seed metering and air-suction technology, applied in the field of air-suction precision seed metering, can solve the problems of seeds affecting germination rate, mechanical damage of seeds, low seedling emergence rate, etc., so as to reduce seed damage and reduce damage rate. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

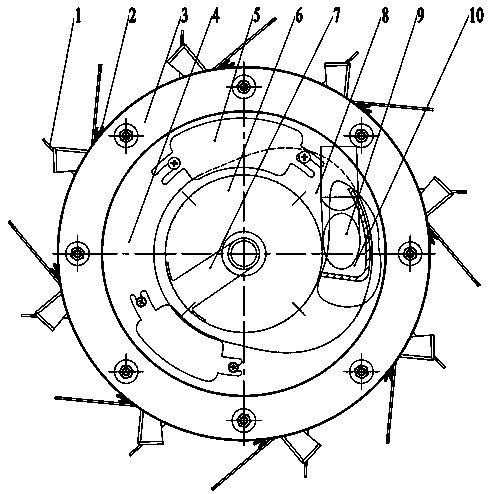

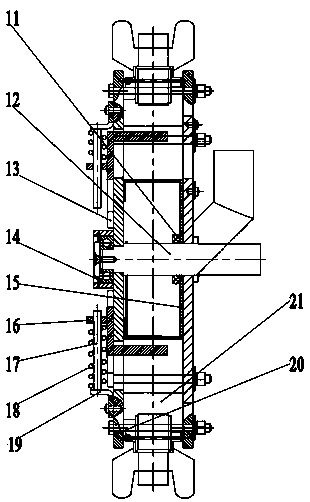

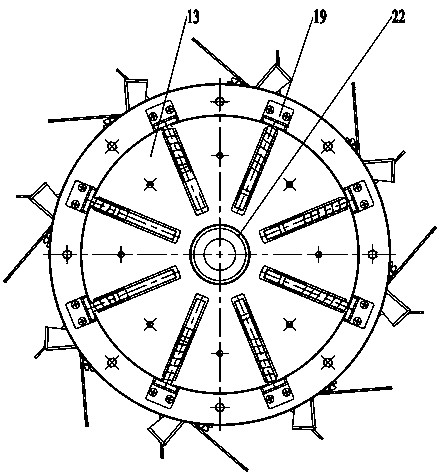

[0025] like Figure 1-9 The shown air-suction peanut precision metering device includes: a seed metering device housing, a seed suction device, and a seed carrying device; the seed metering device housing includes a seed metering device outer moving coil 3, an outer fixed plate 4, an outer It consists of a moving plate 20 and a seed inlet 9; the seed inlet 9 is fixed on the outer fixed plate 4, the outer moving ring and the outer moving plate are assembled with bolts, the duckbill 1 is welded on the belt 21, and under the action of the duckbill spring 2 Opening and closing. Seeds enter the seed chamber 10 from the seed inlet 9 under the action of gravity, and along with the counterclockwise rotation of the seeding disc 6, an air flow channel is formed inside and outside the hole, generating negative pressure suction to adsorb the seeds. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com