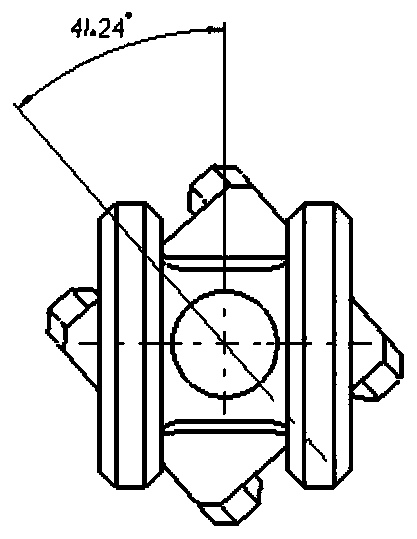

Clamp for inspecting angle of twisting joint notch

An angle and notch technology, applied in the field of fixtures for testing the angle of the torsion joint notch, can solve the problems of low production efficiency, inability to perform accurate measurement, and inability to achieve normal work of parts, achieve convenient clamping, solve detection problems, save money Economic cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

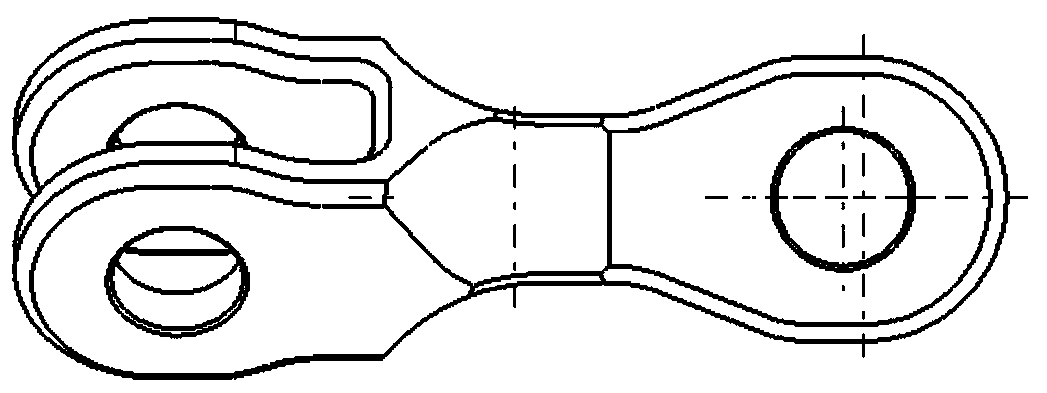

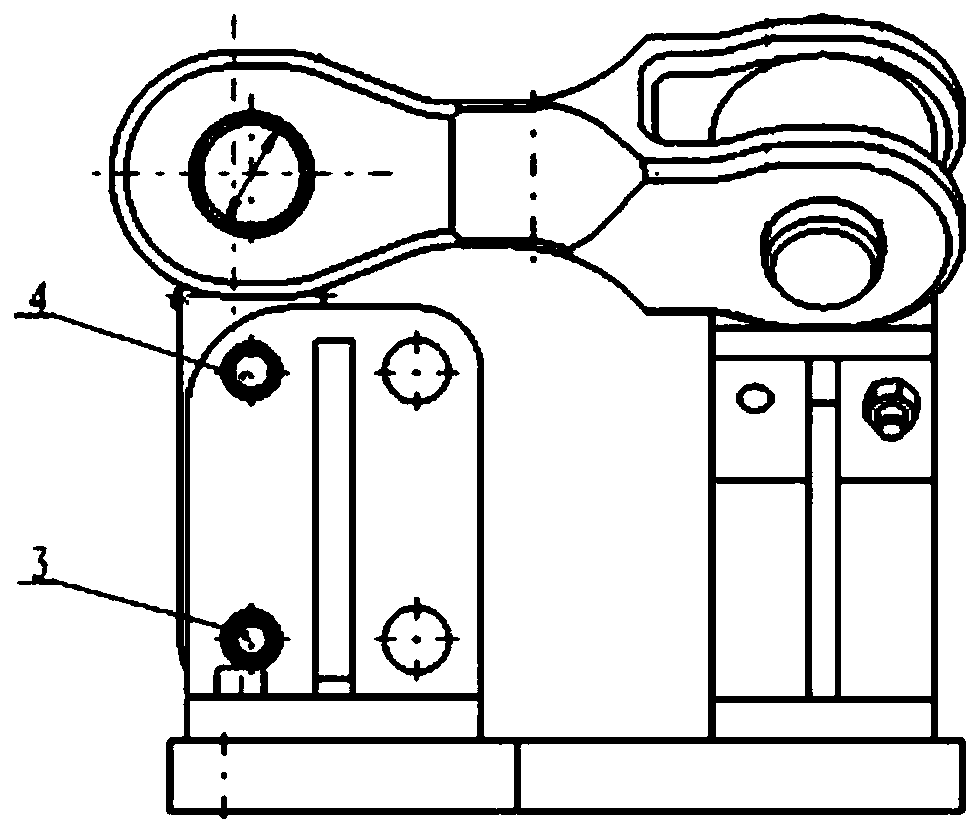

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions. The invention solves the problem of measuring the notch angle of a twist joint, and better guarantees the product quality. When using this fixture, you only need to place the inspection part at the corresponding position, first select the first positioning pin 5 of the corresponding size to insert into the hole of the part, and then select the second positioning pin 6 of the corresponding size to insert into another inspection hole. If it is inserted, it proves that the angle of the part is qualified. If it cannot slide into the notch, it proves that the angle of the part is unqualified, and additional processing is required, or scrapped.

[0020] The fixture has a simple structure and a small shape, which can effectively detect the processing angle, ensure that the product qualification rate of the delivered parts is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com