Device with distance measuring, force specifying and precision taper sleeve dismounting

A taper sleeve, precision technology, applied in the field of mechanical assembly and measurement, can solve the problems of easily damaged taper sleeves, taper holes of damaged parts, complex systems, etc., and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

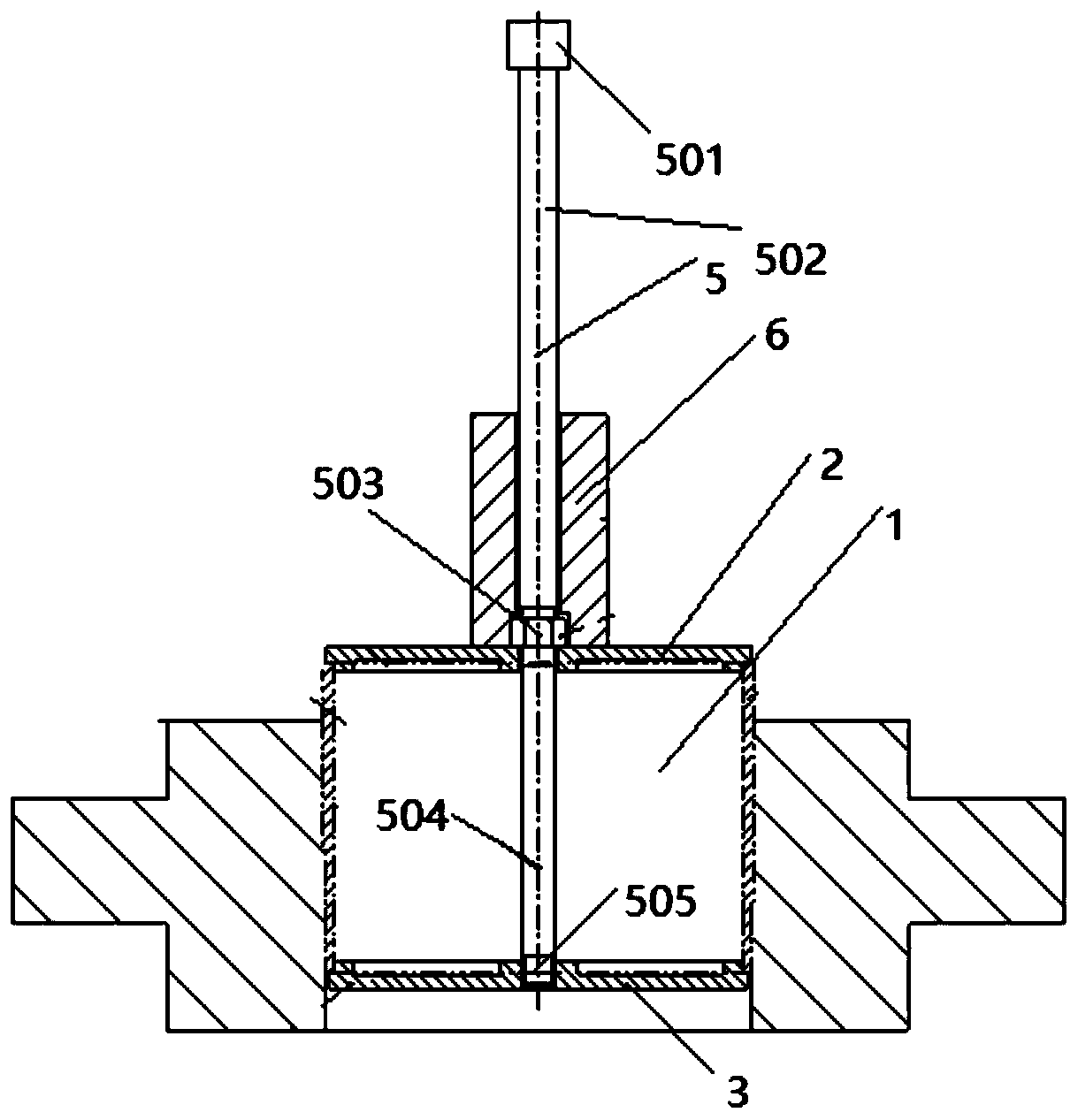

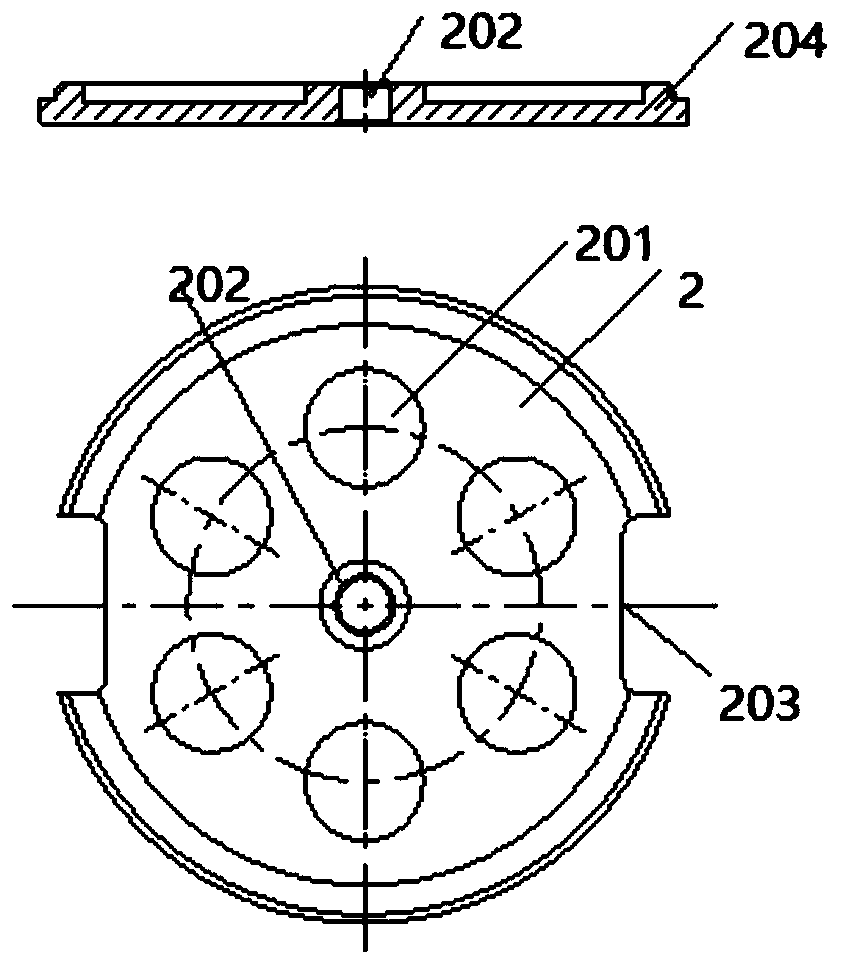

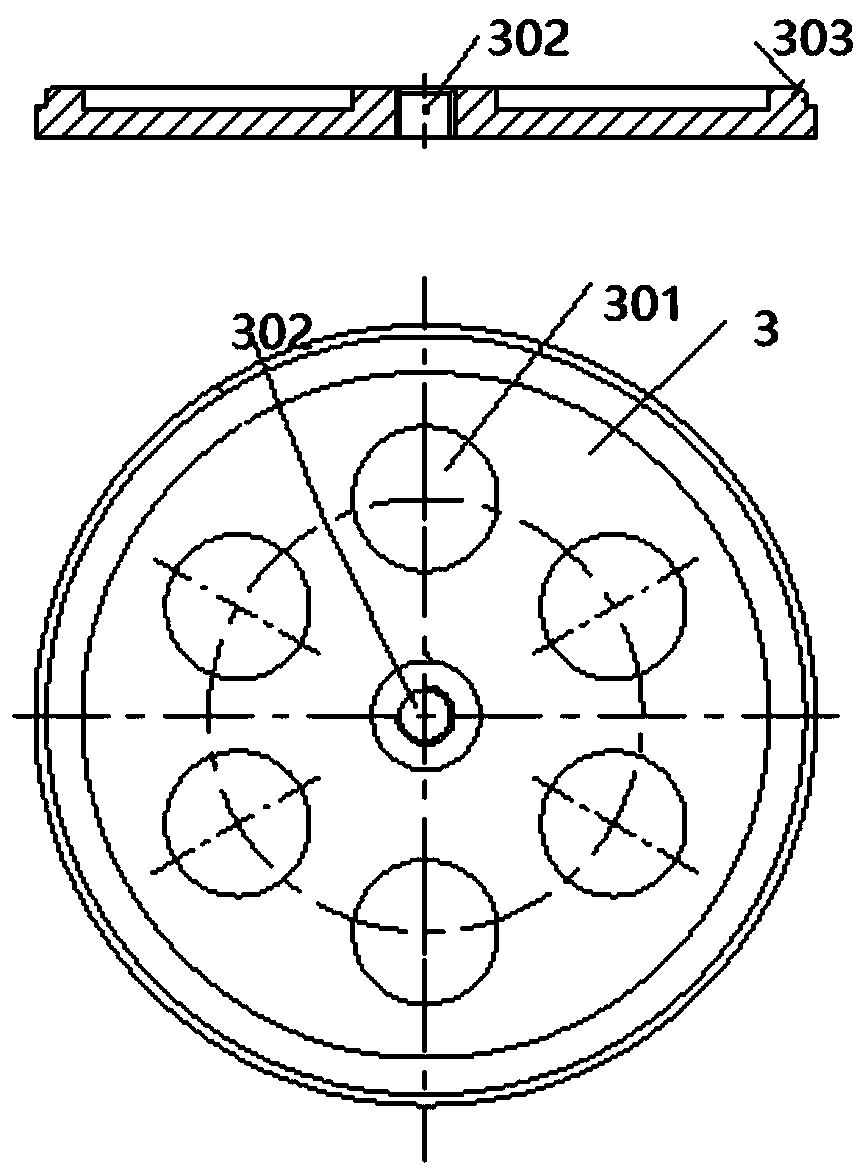

[0026] A device with distance measurement, fixed force and assembly and disassembly of precision taper sleeves, including a taper sleeve 1, the cross section of the taper sleeve 1 is an inverted T shape, the inside of the taper sleeve 1 is a light hole 101, and the taper sleeve 1 The taper is 1:50, the depth of the light hole 101 is set to 160 mm, the thickness of the taper sleeve 1 is set to 5 mm, the upper and lower surfaces of the taper sleeve 1 are provided with glands, and the glands include an upper gland 2 and a lower gland 3, so The diameter of the upper gland 2 is set to 220mm, and the diameter of the lower gland 3 is set to 216mm. The upper gland 2 is provided with a first positioning notch 204 that cooperates with the light hole 101 of the taper sleeve 1. The first positioning The notch 204 is set through the upper gland 2, and the first relief holes 201 are evenly distributed on the upper gland 2, and the first relief holes 201 are evenly distributed on the circumfe...

Embodiment 2

[0028] This embodiment is further optimized on the basis of embodiment 1, specifically, the number of relief holes is set to six.

[0029] In this embodiment, by providing additional lightening holes, it is convenient to reduce the overall weight of the taper sleeve 1 device, so as to save labor and facilitate the operation of the operator.

Embodiment 3

[0031] This embodiment is further optimized on the basis of Embodiment 1 and Embodiment 2. Specifically, the central rod 5 is set in a cylindrical shape, and the weight 6 is set in a cylindrical shape.

[0032] In this implementation, the frictional force between the weight 6 and the center rod 5 is reduced by setting the center rod 5 and the weight 6 in a cylindrical shape, so as to increase the measurement accuracy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com