All-dimensional compatible type unstacking clamp

A compatible and all-round technology, applied in the direction of destacking, stacking, transportation and packaging of objects, it can solve the problem that it is difficult to be compatible with products of the same type and different sizes, cannot well meet automated production, and has a limited scope of application and other problems, to achieve the effect of simple structure, satisfying automatic production and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

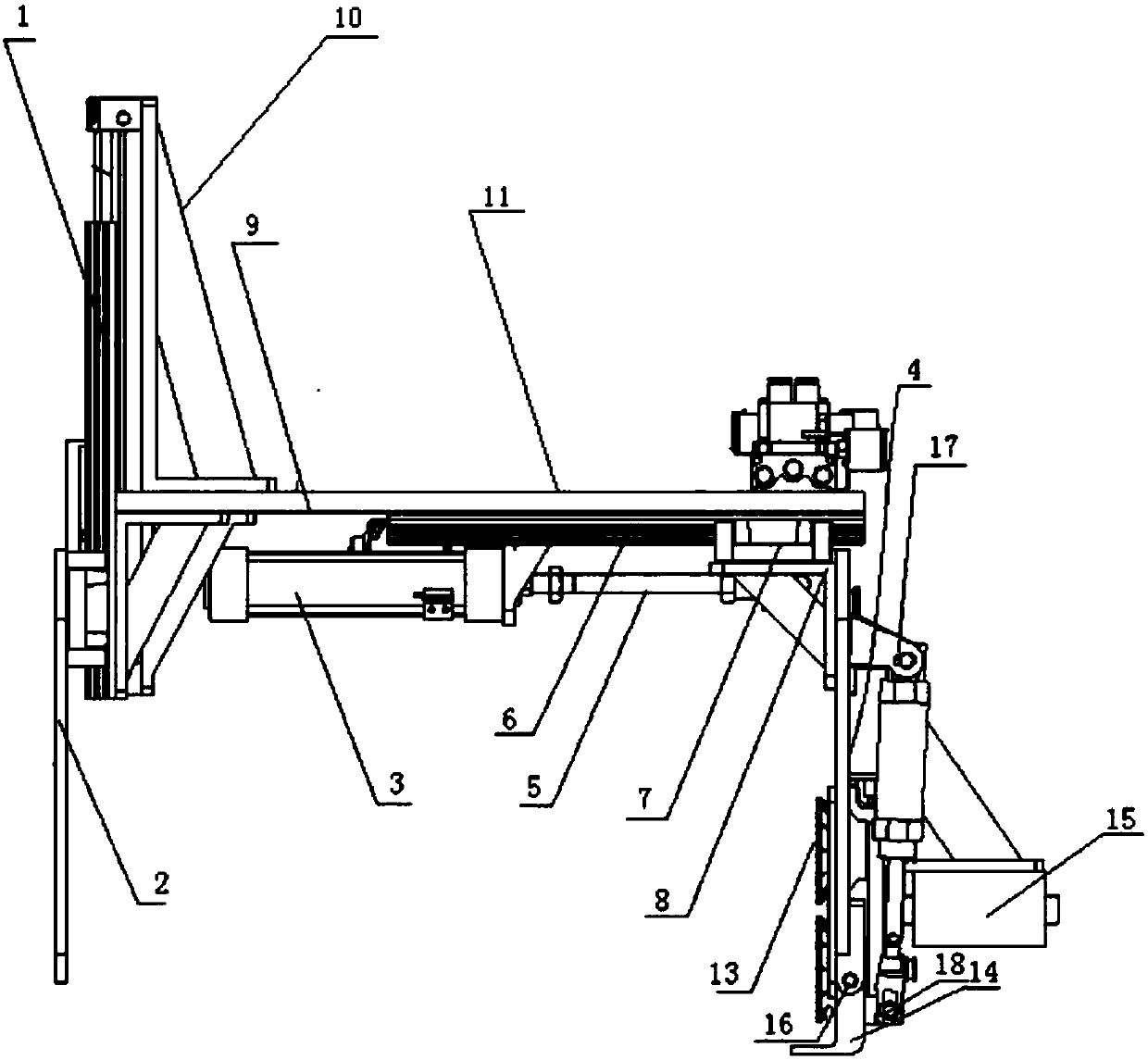

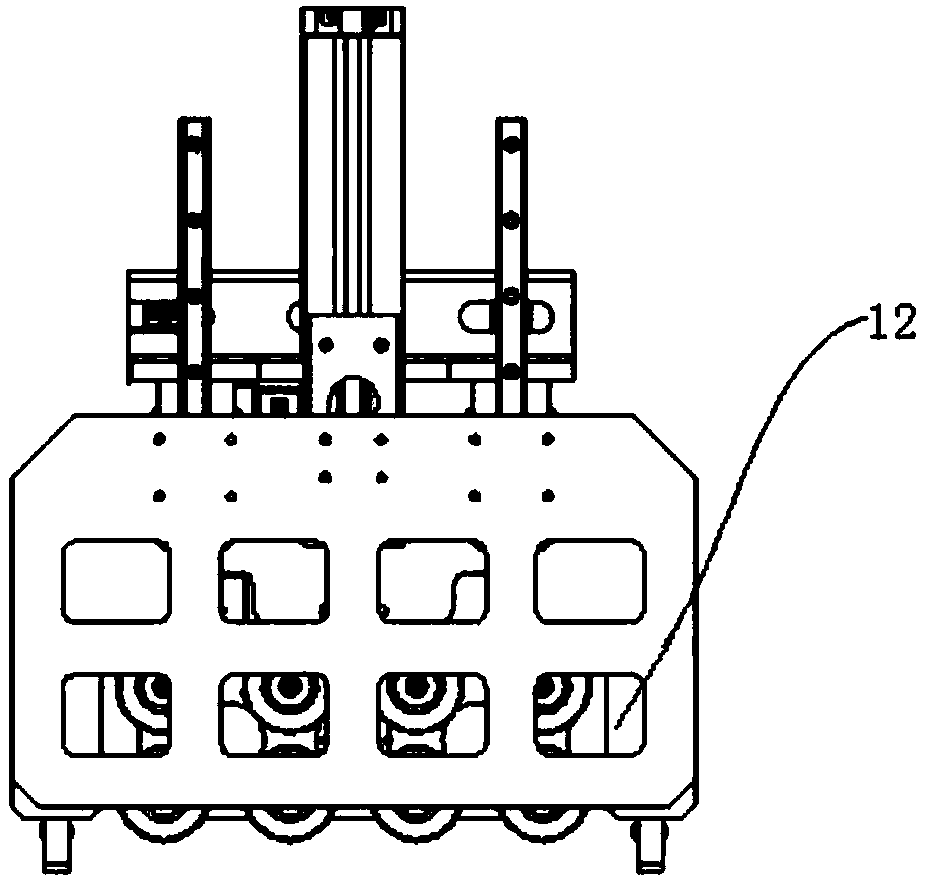

[0035] The present invention provides an all-round compatible destacking jig, the jigs are a group, and each time a box is clamped to perform a task; the jig includes a mounting frame 9 on which a lifting mechanism, a clamping Tightening mechanism, suction cup assembly, hook assembly;

[0036] The lifting mechanism includes a lifting plate cylinder 1, the lifting plate cylinder 1 is connected to the lifting plate 2 through a cylinder push rod, and the lifting plate 2 moves up and down along the vertical direction of the mounting frame 9 under the action of the push rod;

[0037] The clamping mechanism includes a clamping cylinder 3 arranged under the mounting frame 9, the clamping cylinder 3 is connected to the clamping plate 4 through a push rod, and the clamping plate 4 is horizontally along the mounting frame 9 under the action of the push rod direction to move left and right;

[0038] The suction cup assembly includes a suction cup 13 arranged on one side of the clamping ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap