KNN-based ceramic with high-piezoelectric and high-ferroelectric properties and preparation method thereof

A technology of high-voltage electricity and electrical properties, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of poor piezoelectric and ferroelectric properties of KNN-based ceramics that are difficult to apply in practice And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

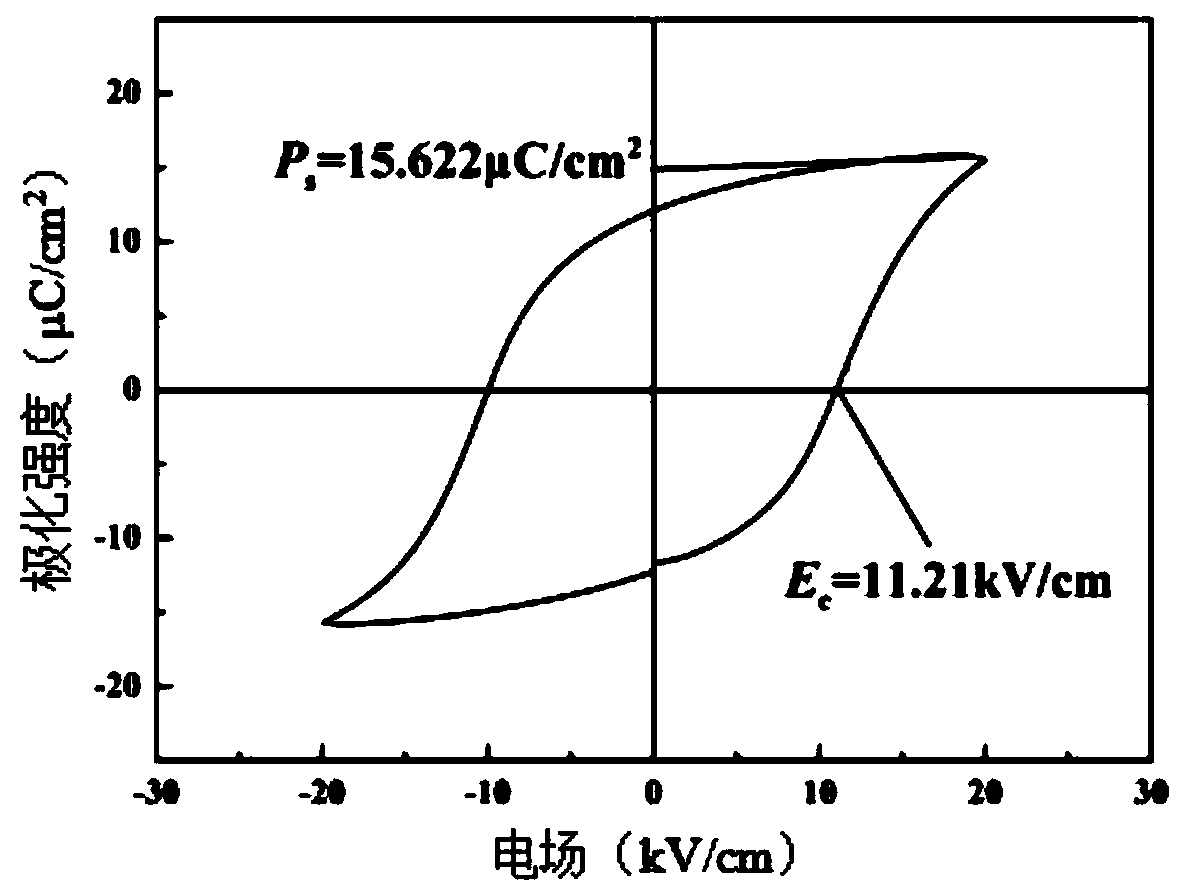

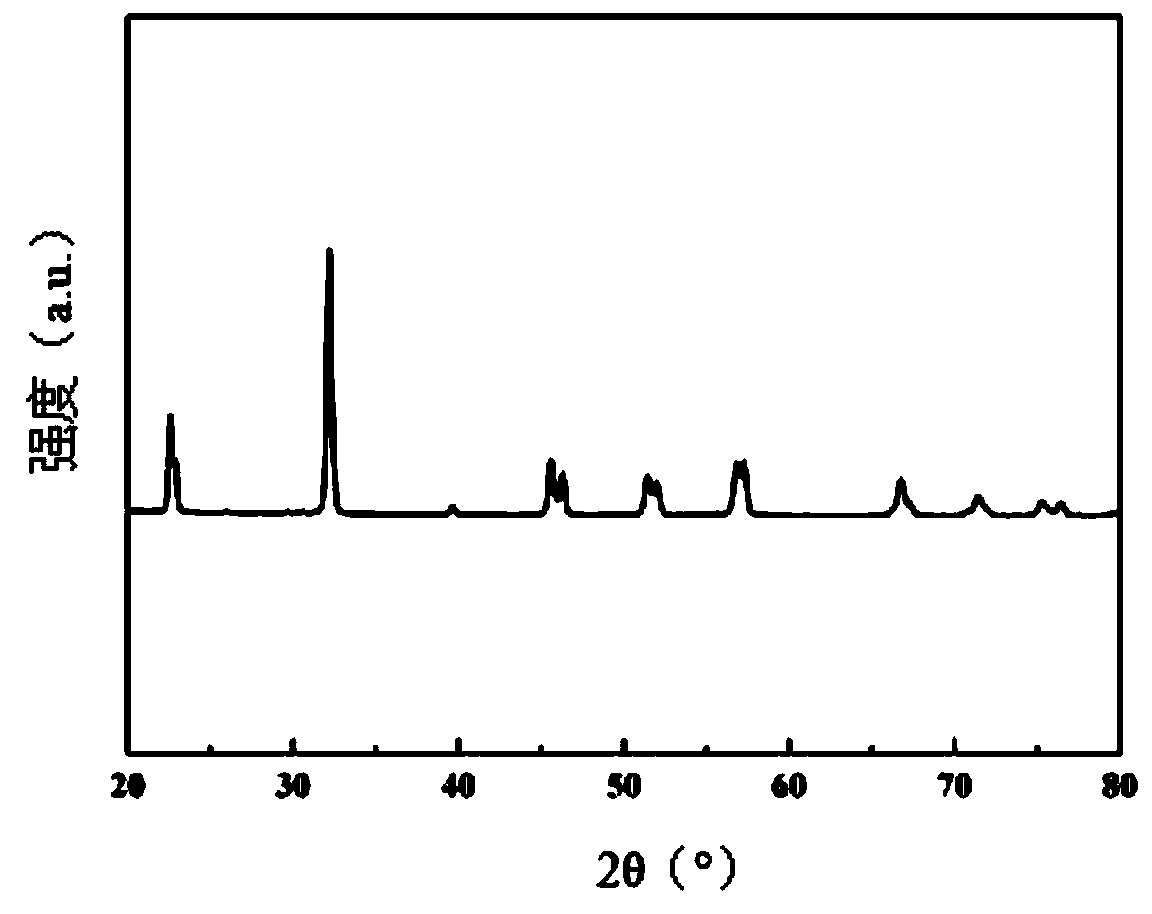

[0027] Embodiment 1: the general formula of a kind of KNN base ceramics with high voltage and high ferroelectric performance in the present embodiment is (K 0.48 Na 0.48 Li 0.04 )(Nb 0.8 Ta 0.2 )O 3 :0.1%MnO 2 ; It is specifically prepared by the following steps:

[0028] Step 1, according to (K 0.48 Na 0.48 Li 0.04 )(Nb 0.8 Ta 0.2 )O 3 The stoichiometric ratio of raw materials were weighed and the mass purity was 99.50% Na 2 CO 3 , K with a mass purity of 99.00% 2 CO 3 , mass purity is 99.90% Nb 2 o 5 Li with a mass purity of 99.99%2 CO 3 , Ta with a mass purity of 99.50% 2 o 5 , and then use absolute ethanol to wet ball mill, dry at 80°C for 10 hours, grind for 10 minutes, and press into tablets;

[0029] Ball milling process parameters in step 1: the rotating speed is 300r / min, the ball milling time is 12h, and the ball-to-material ratio is 1:3.

[0030] Step 2, then place it in an alumina crucible, keep it warm at 900°C for 4 hours, and grind it;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com