A kind of barium, magnesium, tungsten replaces lead zirconate titanate a-position modified piezoelectric ceramics and preparation method thereof

A piezoelectric ceramic and lead zirconate titanate technology, which is applied in the field of piezoelectric ceramics, can solve the problems of low electromechanical coupling coefficient, provide piezoelectric ceramic formula and production method, and fail to meet the requirements of production and application, and achieve the improvement of piezoelectric performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

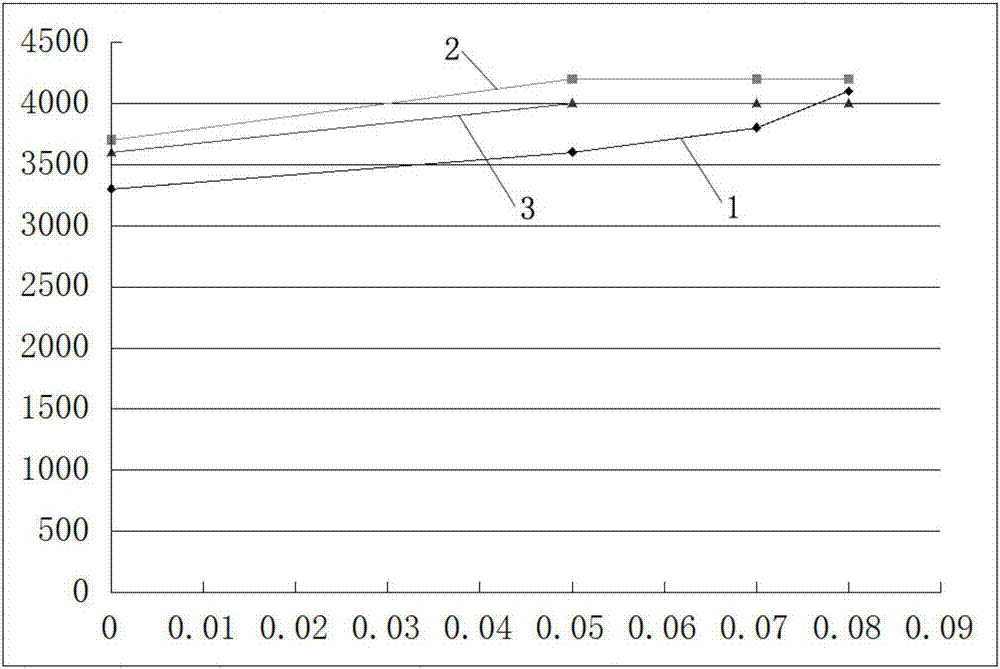

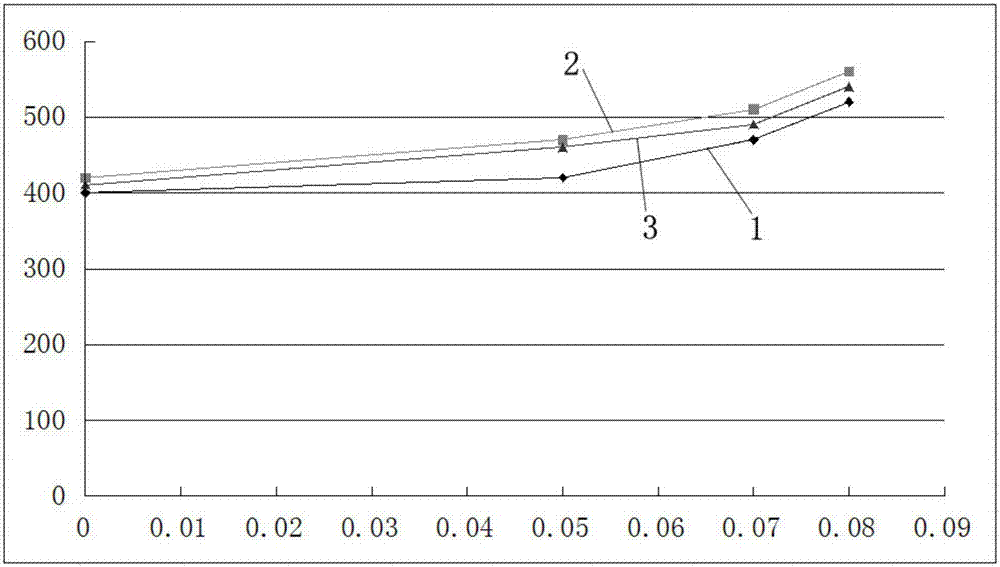

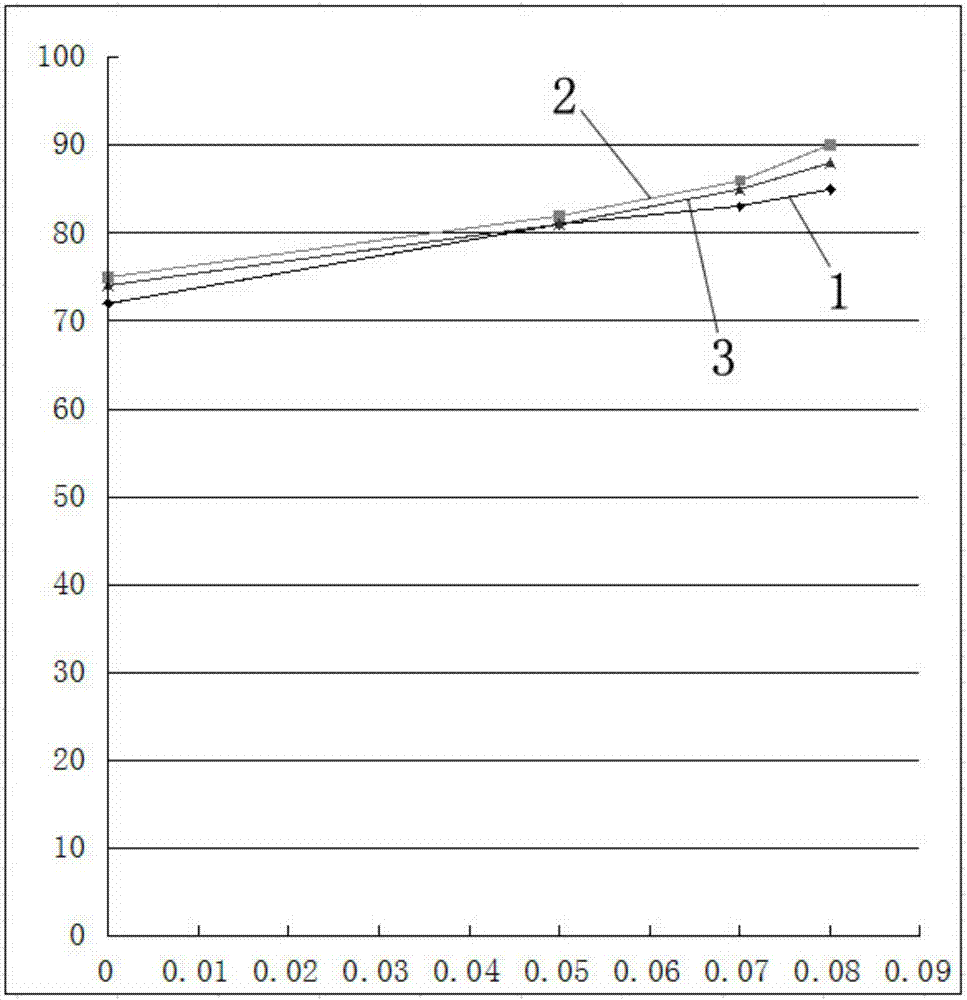

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] The present invention adopts (Ba X Mg Y W Z ) to modify pure PZT piezoelectric ceramics by compound substitution at A site to obtain barium, magnesium and tungsten compound substitution modified piezoelectric ceramics. Among them, barium (Ba 2+ ), magnesium (Mg 2+ ), tungsten (W 3+ ) After the metal ions enter the solid solution, because the valence state is the same as that of Pb 2+ Consistent, and the ionic radius is similar, will occupy Pb 2+ position, thereby creating cation vacancies (mainly lead vacancies) in the lattice. When lead vacancies appear in the unit cell, the crystal lattice is distorted, which is conducive to the domain wall movement, and the domain wall movement can be carried out under the action of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com