BNT-based piezoelectric ceramic and preparation method thereof

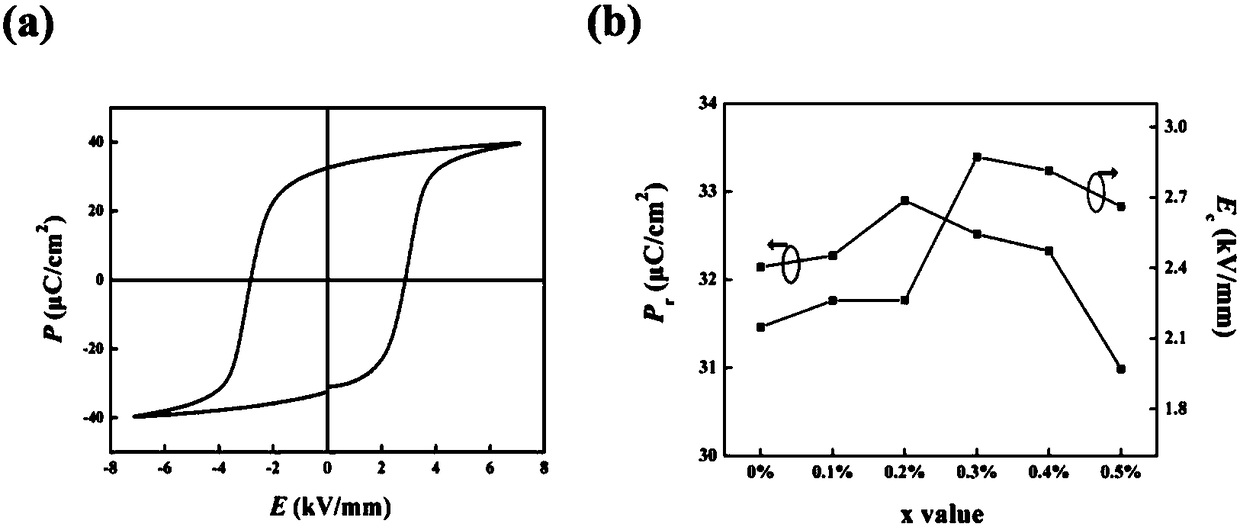

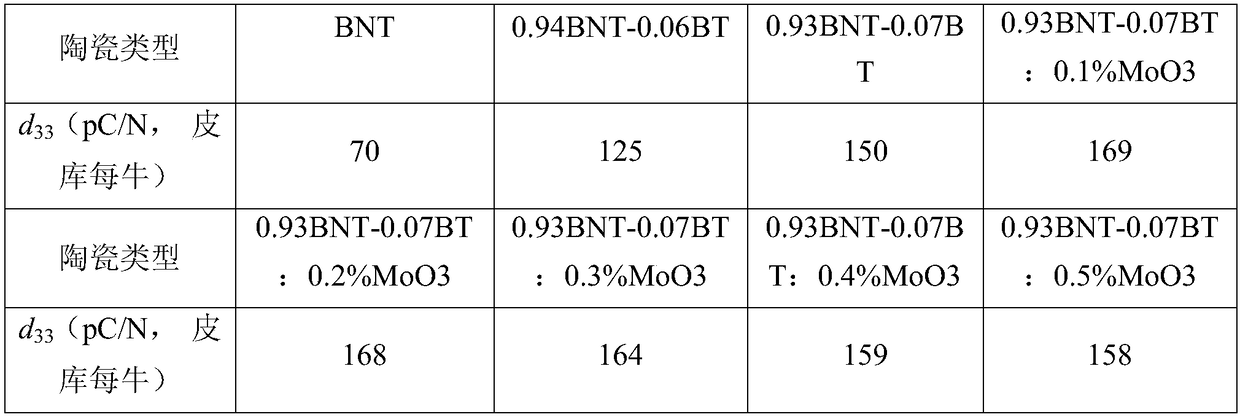

An electrical ceramics and base voltage technology, applied in the field of piezoelectric ceramics, can solve the problems of low high-voltage electrical performance and high leakage current, and achieve the effects of improving piezoelectric performance, reducing coercive field, and alleviating polarization difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

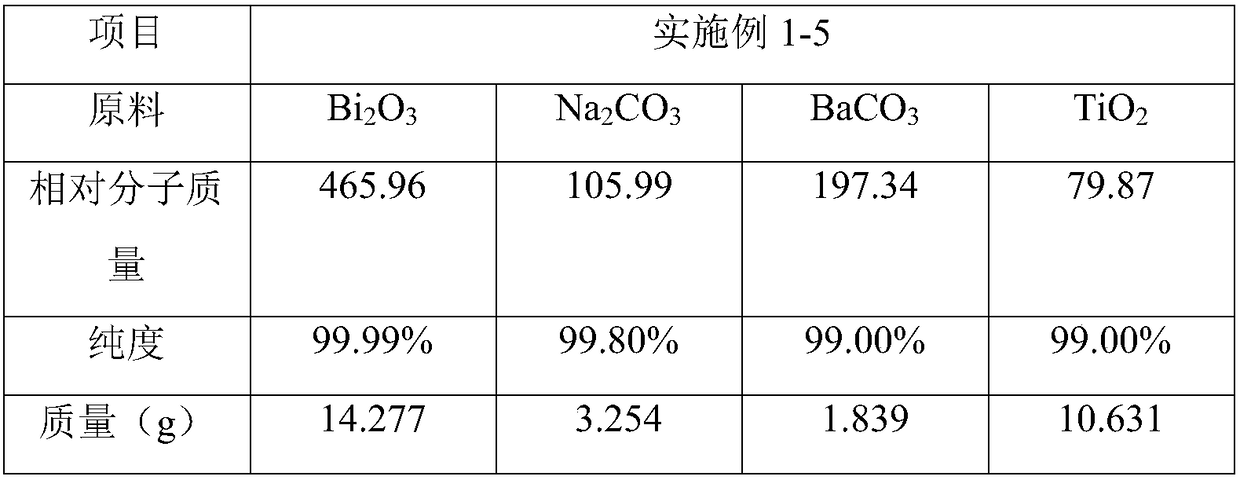

[0029] Example 1. The preparation method of BNT-based piezoelectric ceramics.

[0030] 1) in Bi 2 o 3 、Na 2 CO 3 、BaCO 3 、TiO 2 and MoO 3 As raw material, according to the general formula 0.93Bi 0.5 Na 0.5 TiO 3 -0.07BaTiO 3 :0.1%MoO 3 The stoichiometric ratio weighs each raw material;

[0031] 2) Set Bi 2 o 3 、Na 2 CO 3 、BaCO 3 、TiO 2After mixing with an appropriate amount of ethanol, perform ball milling for 12 hours. The amount of ethanol can be used to submerge the raw material (about 40ml) to obtain a slurry;

[0032] 3) Dry the slurry at 90°C for 2.5 hours, grind it, press it into a disc with a diameter of 30mm, put it into an alumina crucible, and sinter it at 800°C for 3 hours. This is the pre-sintering stage.

[0033] 4) Grind the pre-fired disc, then add the weighed MoO 3 Grind together evenly, add appropriate amount of ethanol, and ball mill for 12 hours for the second time.

[0034] 5) Dry the slurry after secondary ball milling at 90°C for 2.5 ...

Embodiment 2

[0038] Example 2. The preparation method of BNT-based piezoelectric ceramics. Repeat Example 1, the difference between this Example and Example 1 is that each raw material described in step 1) in this Example is according to 0.93Bi 0.5 Na 0.5 TiO 3 -0.07BaTiO 3 :0.2% MoO 3 Weigh each raw material for the stoichiometric ratio. Obtained BNT-based piezoelectric ceramics 0.93BNT-0.07BT: 0.2% MoO 3 .

Embodiment 3

[0039] Example 3. The preparation method of BNT-based piezoelectric ceramics. Repeat Example 1, the difference between this Example and Example 1 is that each raw material described in step 1) in this Example is according to 0.93Bi 0.5 Na 0.5 TiO 3 -0.07BaTiO 3 :0.3%MoO 3 Weigh each raw material for the stoichiometric ratio. Obtained BNT-based piezoelectric ceramics 0.93BNT-0.07BT: 0.3% MoO 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com