Step-type flame-retardant rubber material and preparation method thereof

A flame retardant rubber, stepped technology, applied in the field of stepped flame retardant rubber materials and their preparation, can solve the problems of inability to provide multi-stage flame retardant effect, poor dispersion and fluidity of non-halogen flame retardant materials, etc. The effect of decomposing, improving mechanical strength, and promoting carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

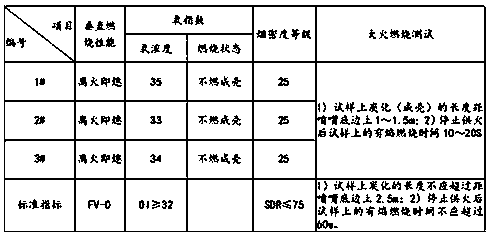

Examples

Embodiment 1

[0072] A stepped flame-retardant rubber material is characterized in that it comprises the following components in parts by weight:

[0073] 80 parts of rubber;

[0074] 80 parts of flame retardant;

[0075] 40 parts of stuffing;

[0076] Auxiliary 0.3 part.

[0077] The flame retardant is an inorganic flame retardant powder coated with a liquid-terminated carboxyl nitrile rubber modified epoxy resin, and the weight of the liquid carboxyl nitrile rubber modified epoxy resin is 0.1% of the weight of the inorganic flame retardant powder , the inorganic flame retardant powder is prepared from inorganic silicon-aluminum shell-forming materials, and the inorganic silicon-aluminum shell-forming materials include:

[0078] SiO 2 30 copies;

[0079] h 3 BO 3 25 copies;

[0080] CaCO 3 5 copies;

[0081] K 2 CO 3 5 copies;

[0082] NaNO 3 5 copies;

[0083] Na 2 O 5 copies;

[0084] Al 2 o 3 1 copy;

[0085] Na 2 SO 4 0.1 copies;

[0086] La 2 o 3 0.05 ...

Embodiment 2

[0096] A stepped flame-retardant rubber material is characterized in that it comprises the following components in parts by weight:

[0097] 120 parts of rubber;

[0098] 200 parts of flame retardant;

[0099] Filling 60 parts;

[0100] Auxiliary 2 parts.

[0101] The flame retardant is an inorganic flame retardant powder whose surface is coated with a liquid-terminated hydroxy nitrile rubber-modified epoxy resin, and the weight of the liquid-terminated hydroxy nitrile rubber-modified epoxy resin is 0.5% of the weight of the inorganic flame retardant powder , the inorganic flame retardant powder is prepared from inorganic silicon-aluminum shell-forming materials, and the inorganic silicon-aluminum shell-forming materials include by weight parts:

[0102] SiO 2 40 copies;

[0103] h 3 BO 3 35 copies;

[0104] CaCO 3 10 copies;

[0105] K 2 CO 3 10 copies;

[0106] NaNO 3 10 copies;

[0107] Na 2 O 10 copies;

[0108] Al 2 o 3 5 copies;

[0109] Na 2 S...

Embodiment 3

[0121] A preferred stepped flame-retardant rubber material is characterized in that it comprises the following components in parts by weight:

[0122] 100 parts of rubber;

[0123] 110 parts of flame retardant;

[0124] Filling 55 parts;

[0125] Auxiliary 1.5 parts.

[0126] The flame retardant is an inorganic flame retardant powder whose surface is coated with a silicone modified epoxy resin, and the weight of the silicone modified epoxy resin is 0.3% of the weight of the inorganic flame retardant powder, and the inorganic flame retardant powder consists of The inorganic silicon-aluminum shell-forming material is prepared, and the inorganic silicon-aluminum shell-forming material includes in parts by weight:

[0127] SiO 2 35 copies;

[0128] h 3 BO 3 30 copies;

[0129] CaCO 3 8 copies;

[0130] K 2 CO 3 8 copies;

[0131] NaNO 3 8 copies;

[0132] Na 2 O 8 copies;

[0133] Al 2 o 3 2 copies;

[0134] Na 2 SO 4 0.2 copies;

[0135] La 2 o 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com