Laser cladding equipment applied to industrial robot

An industrial robot and laser cladding technology, applied in the coating process of metal materials, coatings, etc., can solve problems such as easy generation of pores, and achieve the effects of reducing surface pores, ensuring surface quality, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

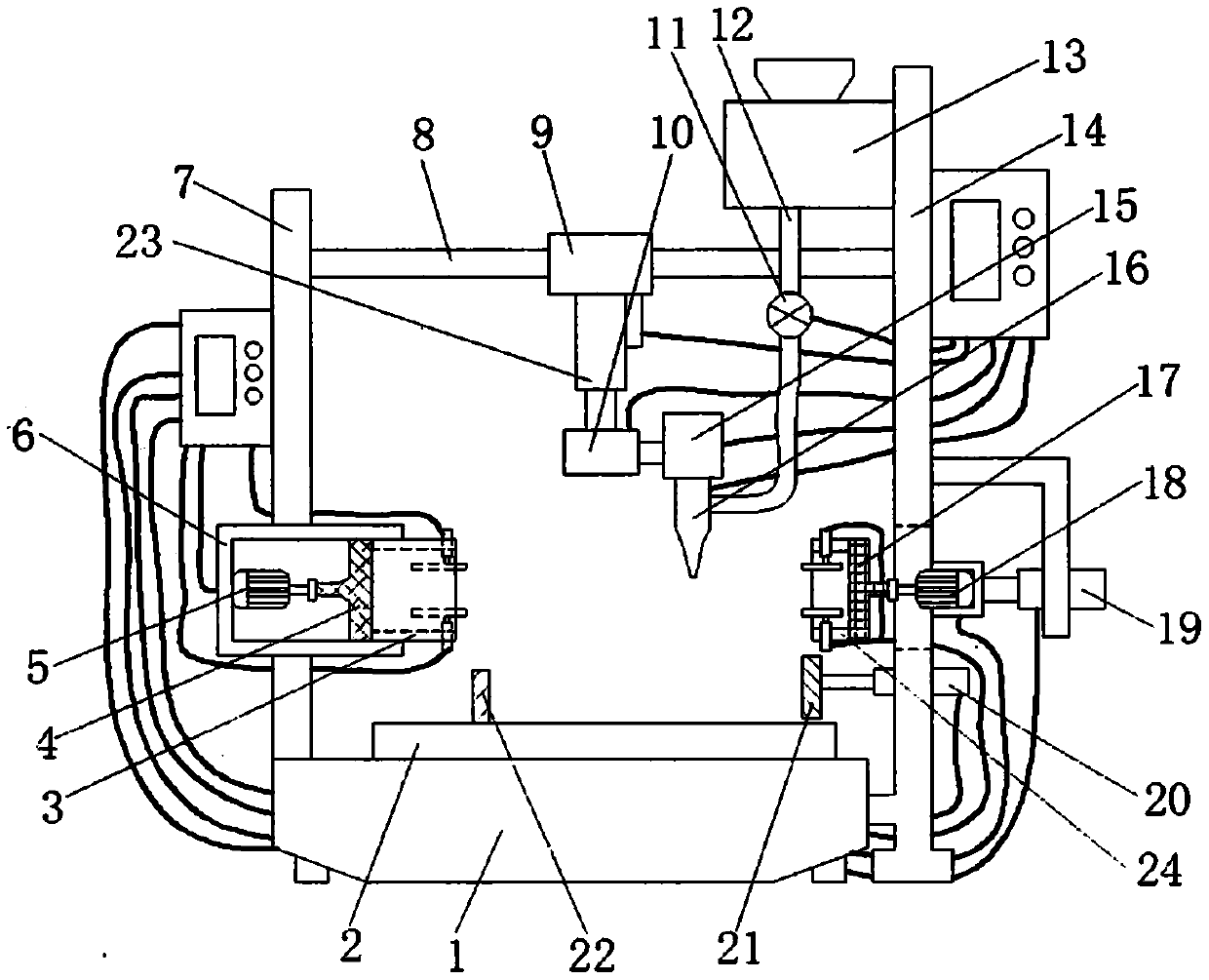

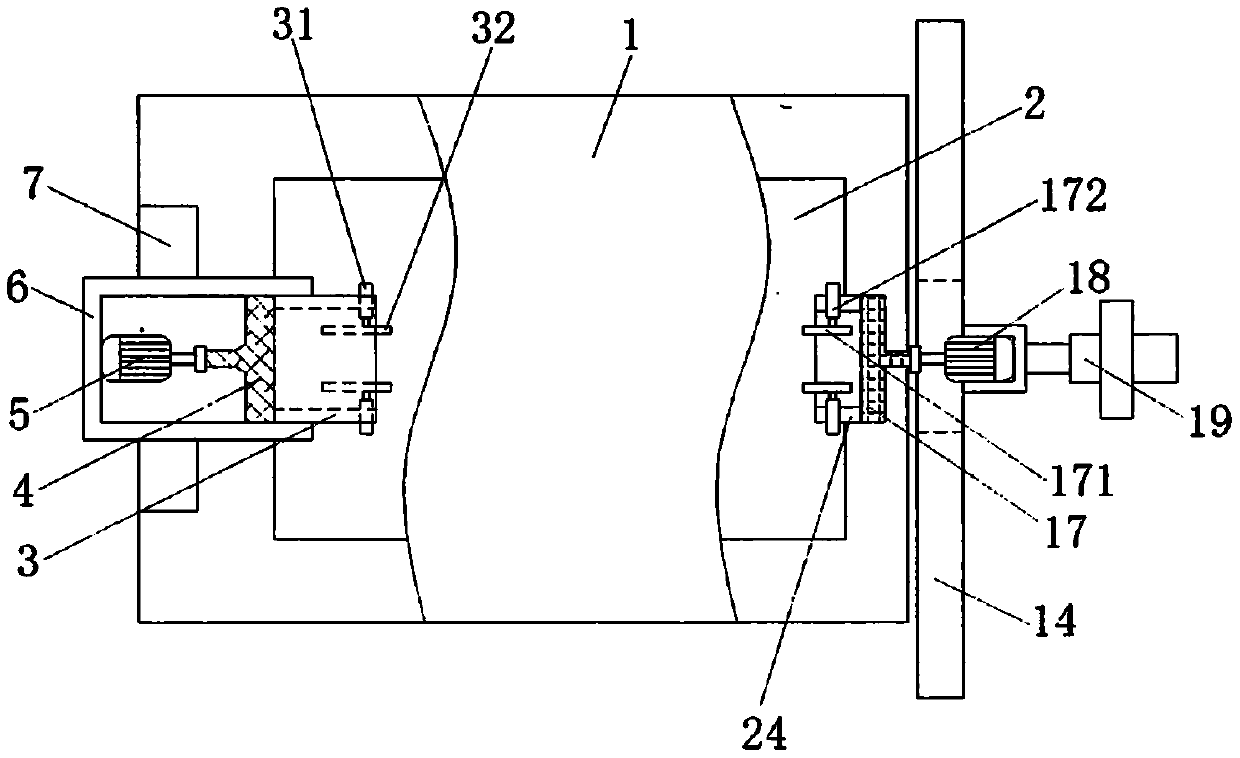

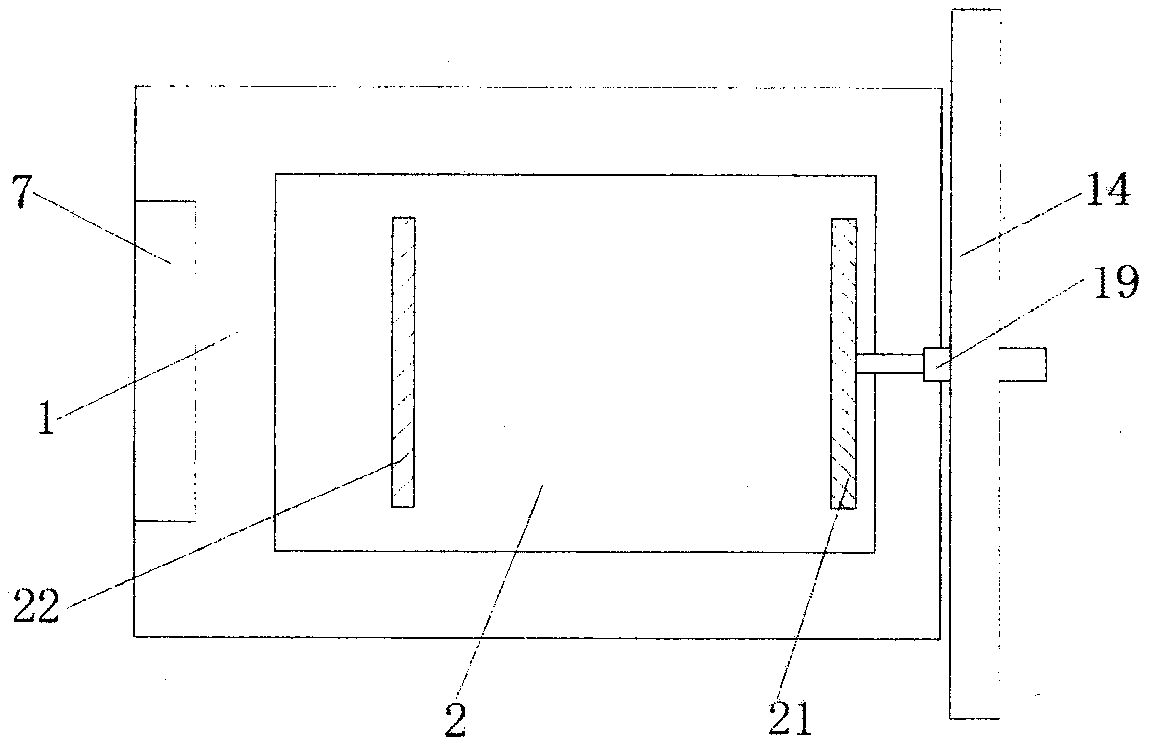

[0034] Example: refer to Figure 1-4 , a laser cladding equipment using industrial robots, including a workbench 1, a first chuck 3, a second chuck 24, an oscillator 10, a laser 15 and a cladding head 16, and the upper part of the workbench 1 is also welded with a second A fixed frame 7, a fixed hole is provided on the first fixed frame 7, and a mounting shell 6 is fixedly arranged with bolts, the inner cavity of the mounting shell 6 is provided with a first motor 5, and the output shaft of the first motor 5 passes through a shaft coupling The transmission is connected with a first connecting turntable 4, the first connecting turntable 4 is fixedly connected with the first chuck 3, the opposite end of the first chuck 3 is provided with a second chuck 24, and the second chuck 24 is fixedly connected by the second The connecting turntable 17 is provided with a second motor 18, and one side bolt of the second motor 18 is fixed with a third electric push rod 19, and the third elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com