Multistage measuring process for sulfur pollutant discharging of steel mill

A pollutant discharge, multi-stage technology, applied in the field of environmental cleaning, can solve the problems of low sewage treatment efficiency, high labor intensity, incomplete treatment, etc., and achieve the effects of easy installation and maintenance, reduced garbage volume, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

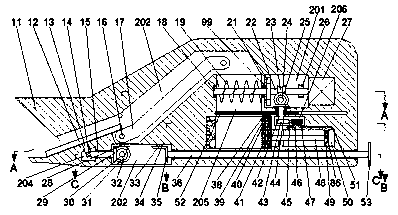

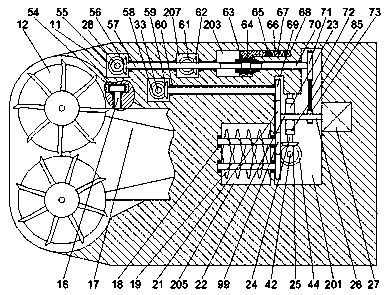

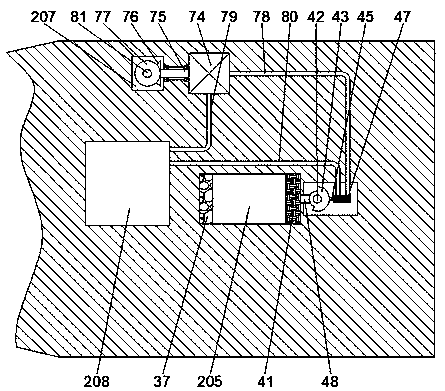

[0016] Combine below Figure 1-4 The present invention will be described in detail.

[0017] Such as Figure 1-Figure 4 As shown, a multi-stage measurement process for sulfur pollutant emission in a steelmaking plant of the present invention includes a fuselage 11 and a first cavity 201 is arranged in the fuselage 11, and a rotating device is arranged in the first cavity 201. The first rotating shaft 22 extending left and right, the right end of the first rotating shaft 22 is power connected with the motor 27 arranged in the right end wall of the first cavity 201, and the outer surface of the first rotating shaft 22 is fixed A first pulley 73 is provided, and a second rotating shaft 70 extending left and right is rotated in the first cavity 201, and a second pulley 71 is provided at the right end of the second rotating shaft 70. A first belt 72 is provided for transmission between the pulley 71 and the first pulley 73, a second cavity 202 is arranged in the left end wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com