Pile feeding method of PHC pile

A technology of PHC piles and feeding piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., to achieve the effects of strong operability, reduced process, and scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure of the present invention will be further described below in conjunction with the drawings and specific embodiments, but it is not a limitation of the present invention.

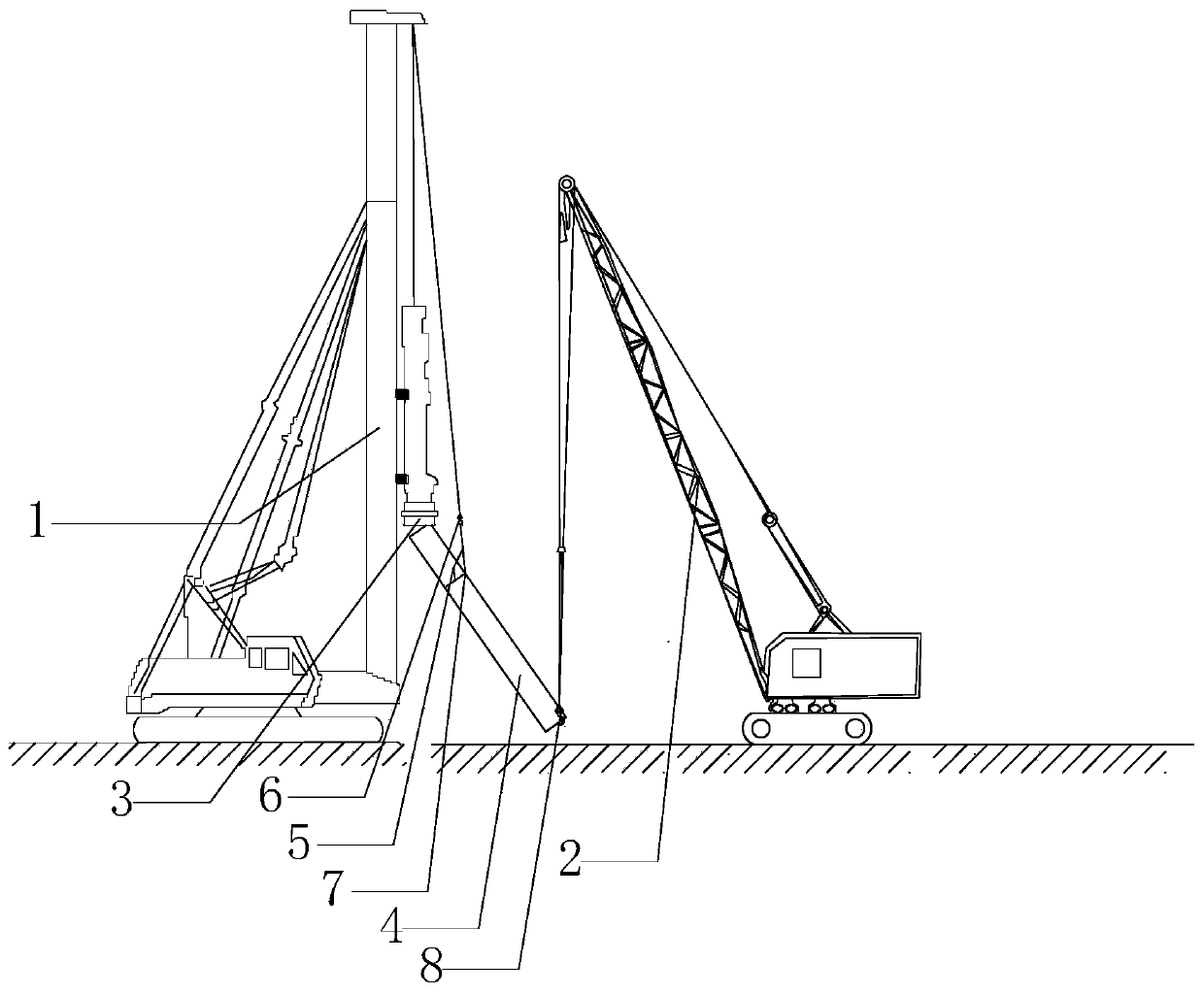

[0028] Such as figure 1 As shown, the embodiment of the present invention discloses a method for feeding PHC piles. The diameter of the PHC pile is 0.8m. The SP135 pile machine and the 10-ton pile hammer are selected, including the following steps:

[0029] a. Wire rope 5 to tie up the connecting end of the first section of PHC pile 4 and the lower section of pile;

[0030] b. Adjust the height of the auxiliary coil hook 6 of the pile driver 1, and hang the wire rope 5 straight; the wire rope 5 is tied to the pile end about 2m.

[0031] c. Hook the tip of the first PHC pile with 8 crane hooks;

[0032] d. The pile crane lifts the PHC pile, and crane 2 simultaneously lifts the tip of the PHC pile material;

[0033] e. The pile driver raises the height of the PHC pile tip, while adjusting the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com