Low shear single well mixed liquid injection allocation equipment

A low-shear, liquid-mixing technology, used in wellbore/well components, production fluids, earth-moving drilling, etc., can solve problems such as easy blockage of the device, inability to accurately adjust the viscosity of the dispensing device, and failure to meet the requirements of polymer injection. Accurate pressure regulation, compact structure and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

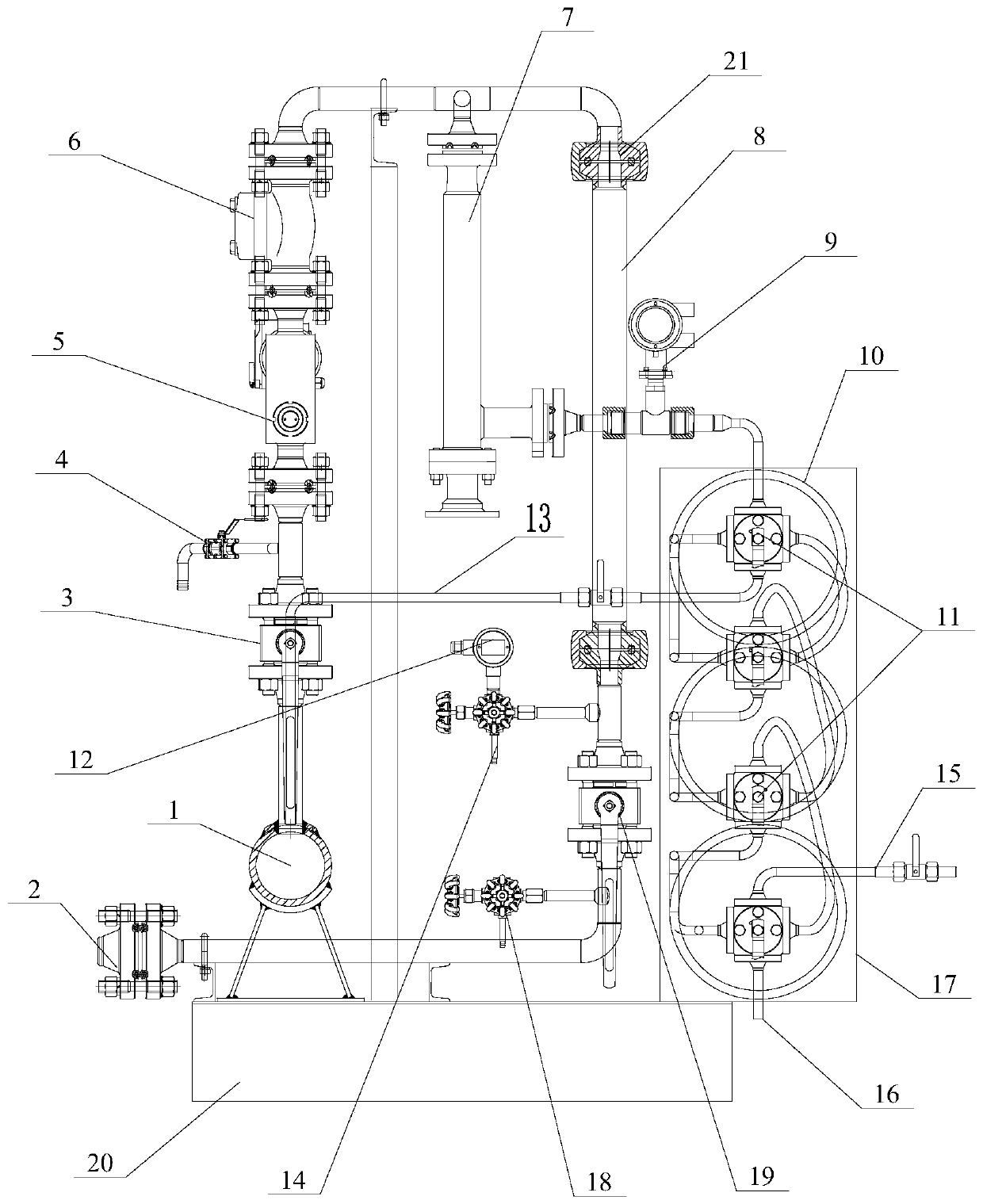

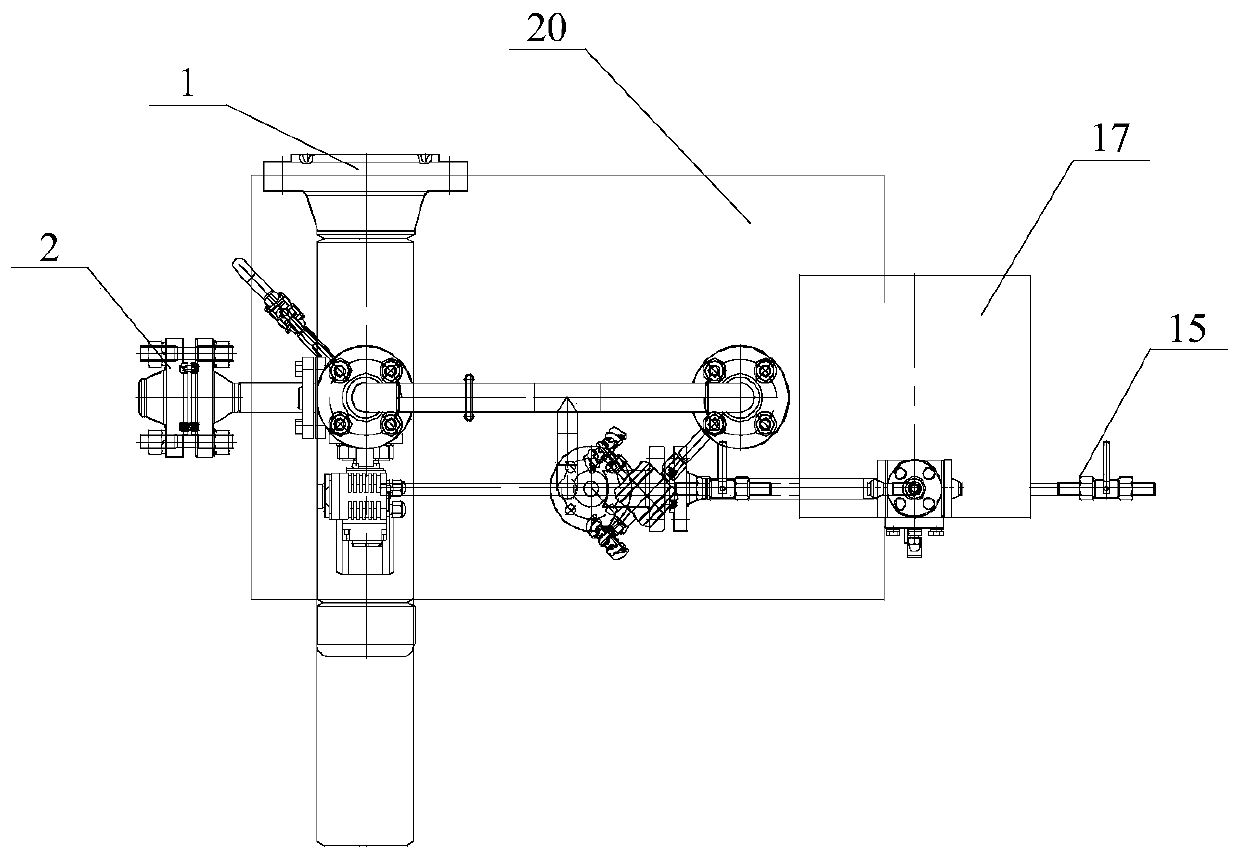

[0032] The invention provides a low-shear single-well mixed-fluid dispensing device. The whole device has a compact structure, is easy to install, and can be adjusted flexibly. gathering requirements. The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as figure 1 and figure 2 As shown, the present invention provides a low-shear single-well mixed liquid injection device, which includes a liquid injection pipeline and a pressure regulating polymer injection device. Now the two parts of the structure are explained separately.

[0034] 1. Liquid injection pipeline

[0035] The liquid injection pipeline is provided with a high-pressure ball valve and a pressure transmitter 21, and also includes a flow measurement and control assembly 5, a check valve 6, a mixed liquid inlet and a mixer 8 arranged sequentially on the liquid injection pipeline along the liquid injection direction. The flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com