Device for cooling heating part used for supporting or driving rotary part

A technology for cooling devices and heat-generating components, applied in cooling/ventilation devices, electromechanical devices, bearing cooling, etc., can solve problems such as increasing the risk of high-speed equipment operation, achieve efficient cooling, and achieve cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

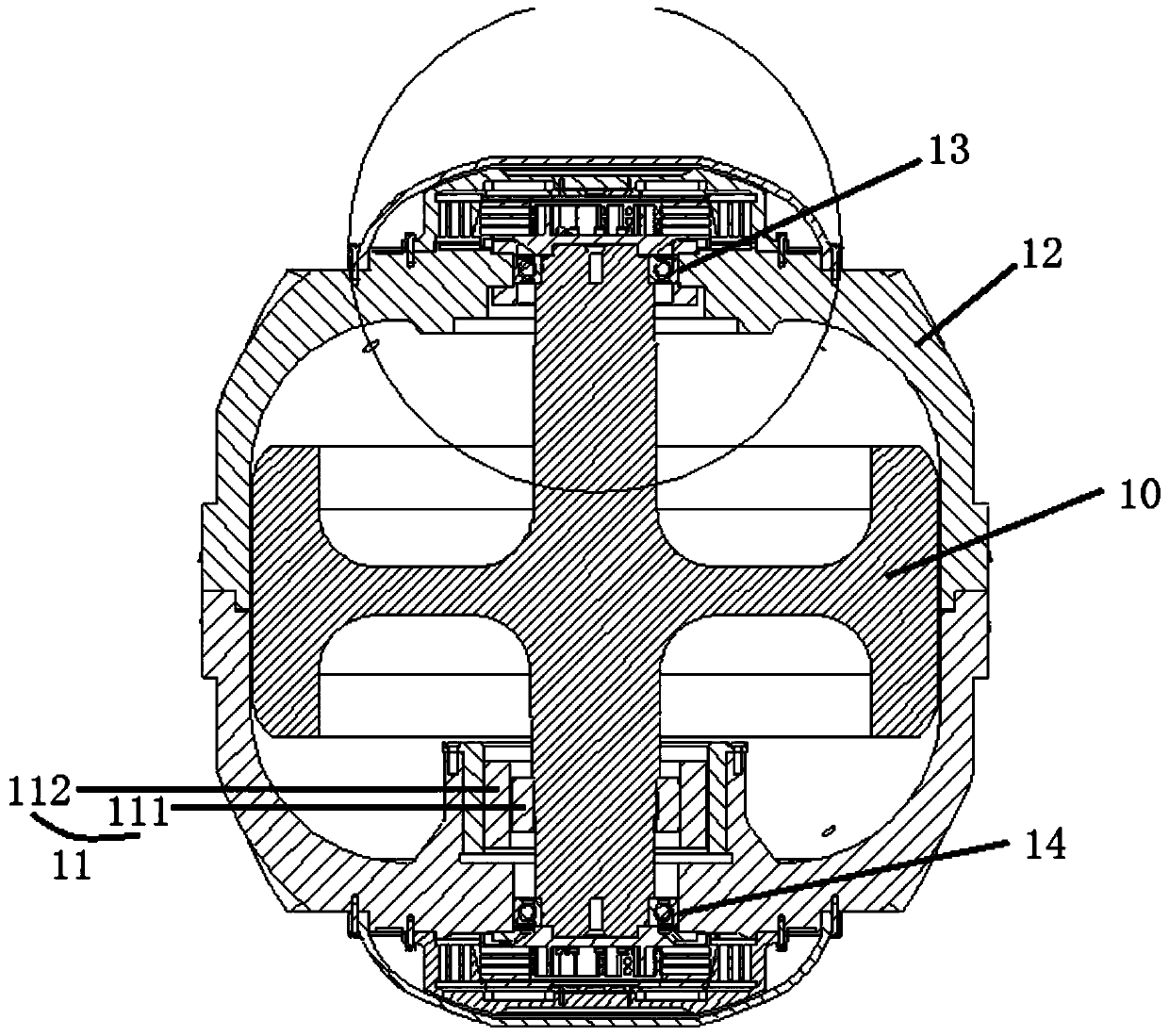

[0044] See Figure 1-Figure 4 , this embodiment provides an implementation of the cooling device.

[0045] figure 1 Shown is a gyro anti-rolling device for a ship, wherein a steel flywheel 10 rotates at a high speed in a housing 12 driven by a high-speed motor 11, and the housing 12 can be used as a closed space to vacuumize to form a low-pressure environment, and can also be filled. Other gases with a density lower than air are injected to reduce the wind resistance of the flywheel 10 rotating at high speed, and the bearings 13 and 14 are used to support the high-speed operation of the flywheel 10.

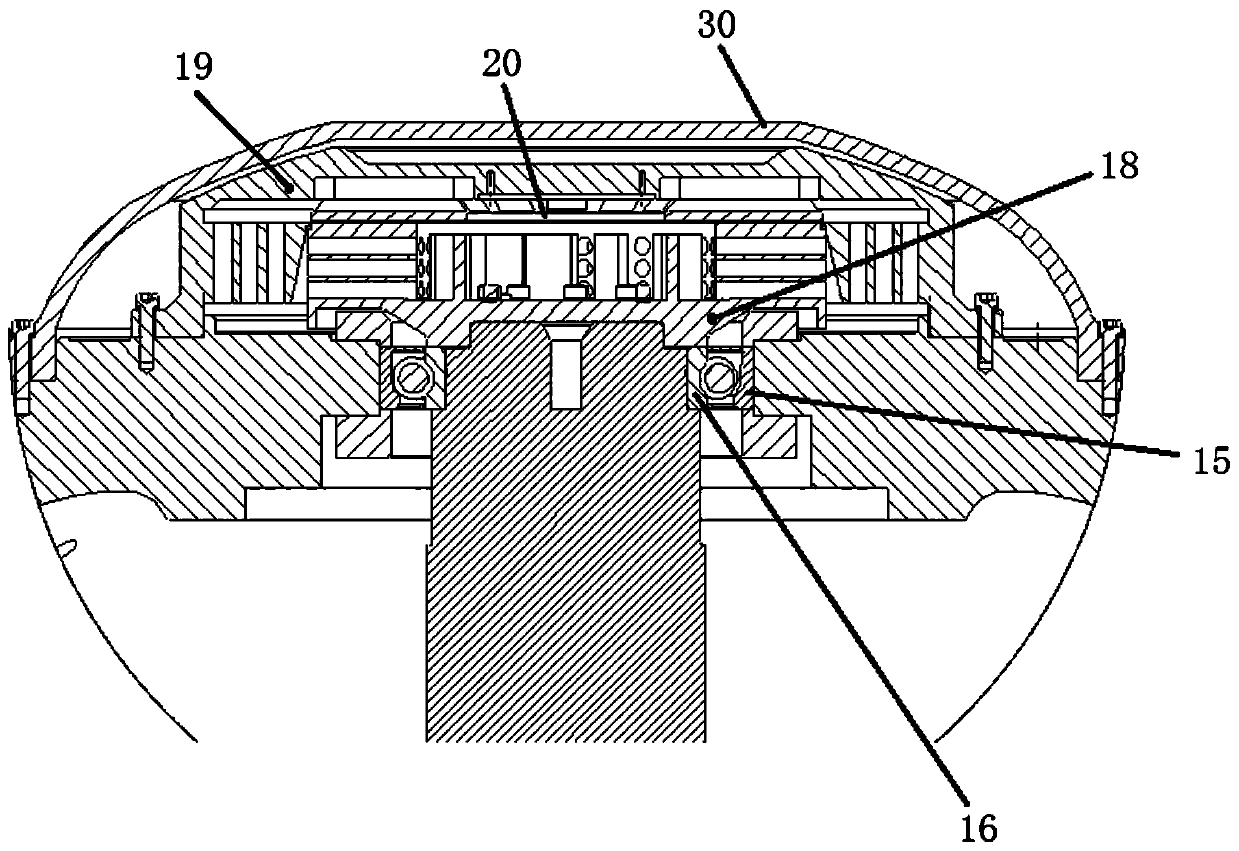

[0046] When the flywheel 10 runs at high speed, a large amount of heat will be generated on the inner / outer rings of the bearings 13, 14 and the motor 11, wherein the bearing outer ring 15 (please refer to figure 2 shown) and the heat of the motor stator 112 can be conducted to the housing 12 and dissipated, but the bearing inner ring 16 (please refer to figure 2 As shown) a...

Embodiment approach

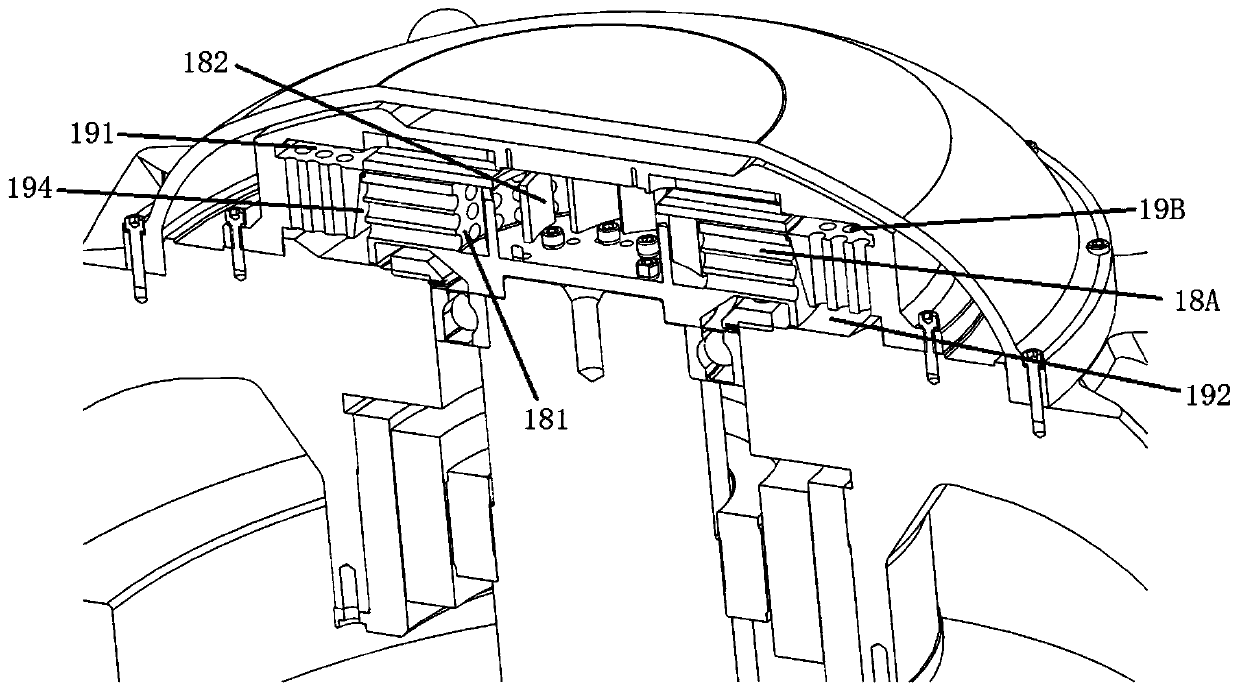

[0065] The design of moving heat sink can also be taken as Figure 6 By reducing the number of blades 182' and increasing the area of each blade 182', the heat dissipation capacity of the moving heat sink is improved.

[0066] The cooling effect evaluation of the cooling device of the present embodiment is as follows:

[0067] In the present embodiment, the total surface area of the movable heat sink is set to be 0.43m 2 , the total surface area of the static heat sink is 0.47m 2 , according to the heat convection calculation formula

[0068] q=h c A dT (1)

[0069] in,

[0070] q heat dissipation power, the unit is (W);

[0071] A heat dissipation surface area, the unit is (m 2 );

[0072] hc convective heat transfer coefficient, unit is (W / (m 2 ℃);

[0073] dT is the temperature difference between the fluid and the cooling surface, in (°C).

[0074] Under the high-speed rotation of the rotor, the gas flow linear velocity will reach more than 60m / s, which is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total surface area | aaaaa | aaaaa |

| Total surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com