Built-in accommodating groove type electric melting pipe fitting

A technology of electrofusion pipe fittings and holding tanks, which is applied in the direction of pipes/pipe joints/pipe fittings, pipe connection layout, mechanical equipment, etc., which can solve the problems of poor firmness and achieve the effects of convenient alignment and fixing, simple molds, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

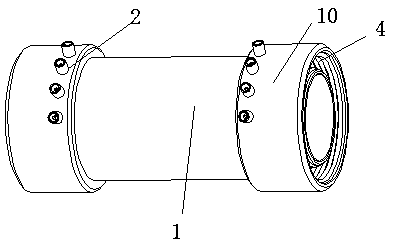

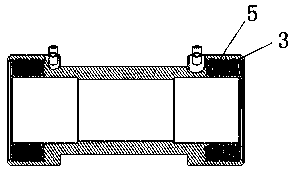

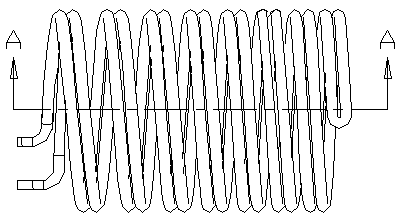

[0052] Such as figure 1 with figure 2 As shown, the present invention discloses a built-in accommodating tank type electrofusion pipe fitting, which includes a pipe body 1 and eight lugs 2 arranged on the pipe body, and the pipe body includes two ends 11 and a first heating wire 3 , the end face walls of both ends are inwardly recessed to form an integral annular accommodation groove 4; the first hot-melt material layer 5 is fixed on the outer surface of the accommodation groove and the inner surface of the accommodation groove; and the first heating wire It is fixed in the first hot-melt material layer; the two ends of the first heating wire are respectively electrically connected to the terminal. The terminal is arranged on the outer wall of the end of the pipe body. The terminals are all installed at the end away from the nozzle. The outer diameters of the two ends of the pipe body are smaller than the outer diameter of the middle part. The included angle between the c...

Embodiment 2

[0056] Such as Figure 4 , Figure 5 ; The difference between Embodiment 2 and Embodiment 1 is that a built-in accommodation tank type electrofusion pipe fitting includes a pipe body and eight terminals arranged on the pipe body, and the pipe body includes two ends and a first heating wire 3. The end walls of both ends are inwardly recessed to form an integral annular accommodation groove 4; the first hot-melt material layer 5 is fixed on the outer surface of the accommodation groove and the inner surface of the accommodation groove; and the first electric heater The wire is fixed in the first heat-melt material layer; both ends of the first heating wire are electrically connected to the terminal head respectively. A second hot-melt material layer 6 is fixed on the inner wall surface of the pipe body, and a second heating wire 7 is fixed on the second hot-melt material layer, and the second heating wire is externally connected to a terminal. There are two pairs of terminals,...

Embodiment 3

[0058] Such as Image 6 , Figure 7 , Figure 8 As shown, the difference between embodiment 2 and embodiment 1 is that the outer diameters at both ends of the tube body are larger than the outer diameter at the middle. The angle between the centerlines of the two ends is 180°. Both ends are provided with annular receiving grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com