Geothermal single-well reinforced heat exchange system

A technology that enhances heat exchange and geothermal wells, and is applied in heating systems, geothermal power generation, and heat collectors that use groundwater as a working fluid. The problem of low well output and other problems can be achieved, and the effect of cost reduction, improvement of utilization rate and output power can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

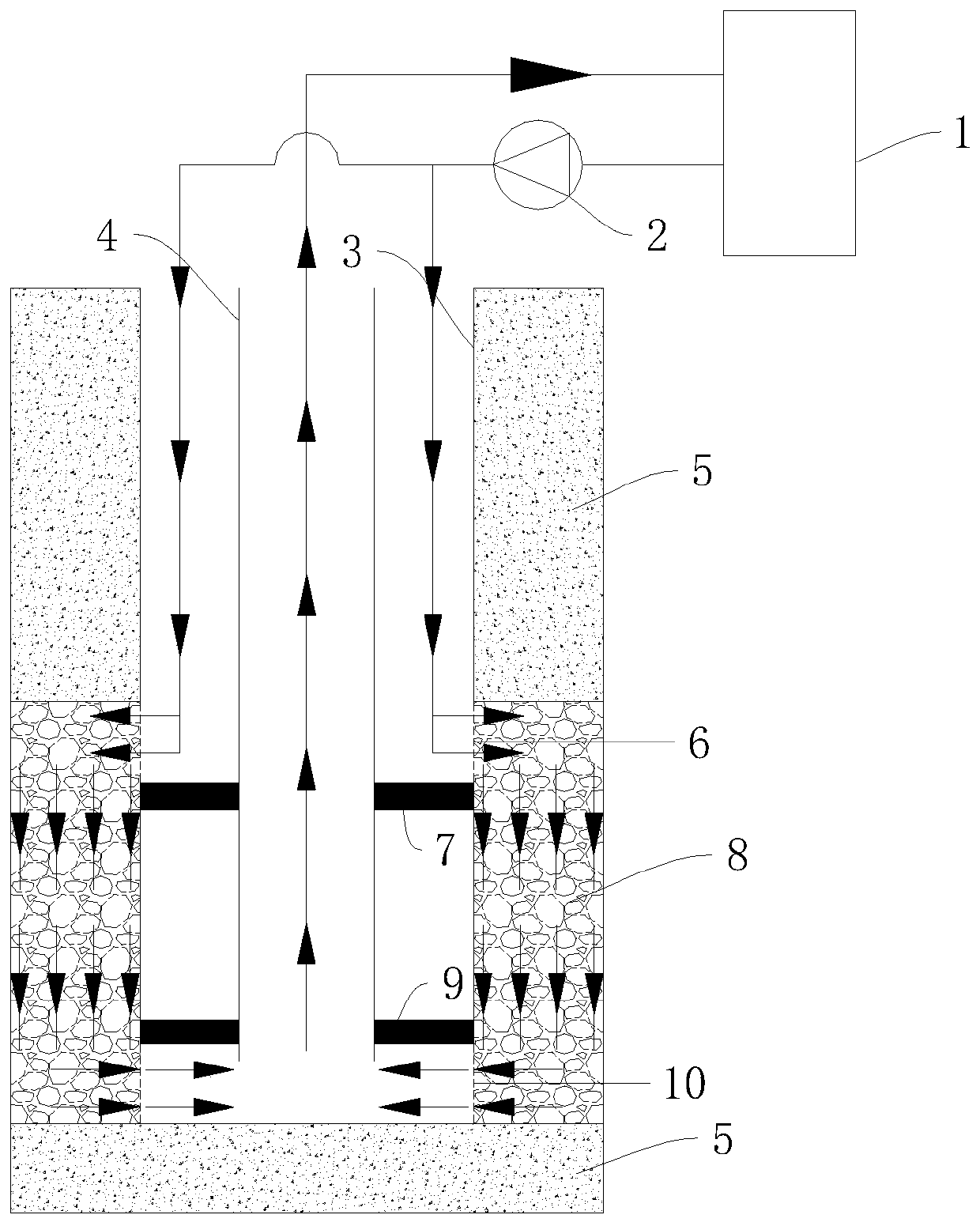

[0018] Such as figure 1 As shown, a geothermal single-well enhanced heat exchange system includes an artificial porous system 8 arranged underground, a heating component arranged on the surface, and an underground heating assembly arranged underground. Below are all tight rock layers 5 . The underground heating components include a geothermal well and an insulation pipe 4 arranged in the middle of the geothermal well. The insulation pipe 4 is made of PPR pipe. The geothermal well needs to penetrate the dense rock layer 5 and the artificial porous system 8 arranged underground to ensure 8 utilization. The inner wall of the geothermal well adopts a metal well wall 3, and the insulation pipe 4 communicates with the wellhead and the bottom of the geothermal well. The water inlet channel, the water outlet channel and the heat-taking and heating components on the surface are combined to form a heat-taking cycle.

[0019] The metal well wall 3 is provided with an upper screen 6 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal thickness | aaaaa | aaaaa |

| Lateral thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com