Textile workshop air conditioner system PLC automatic control method

A technology for air-conditioning systems and workshops, which is applied in the direction of control input involving air characteristics, space heating and ventilation control input, heating and ventilation control systems, etc. It can solve problems such as insufficient control precision of control strategies, lagging workshop temperature and humidity adjustment, etc. , to achieve the effect of ensuring production process requirements, solving hysteresis and high energy consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

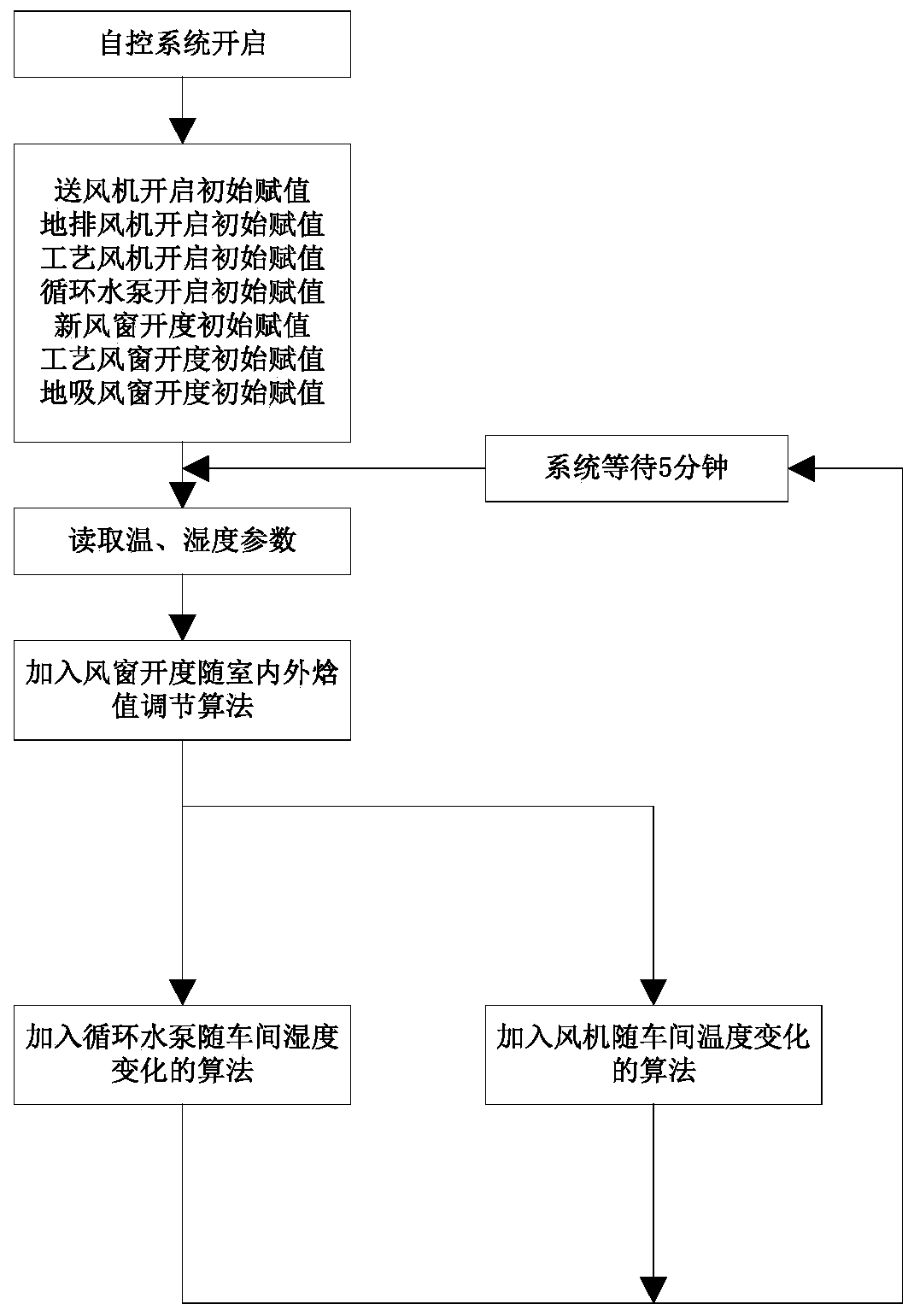

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

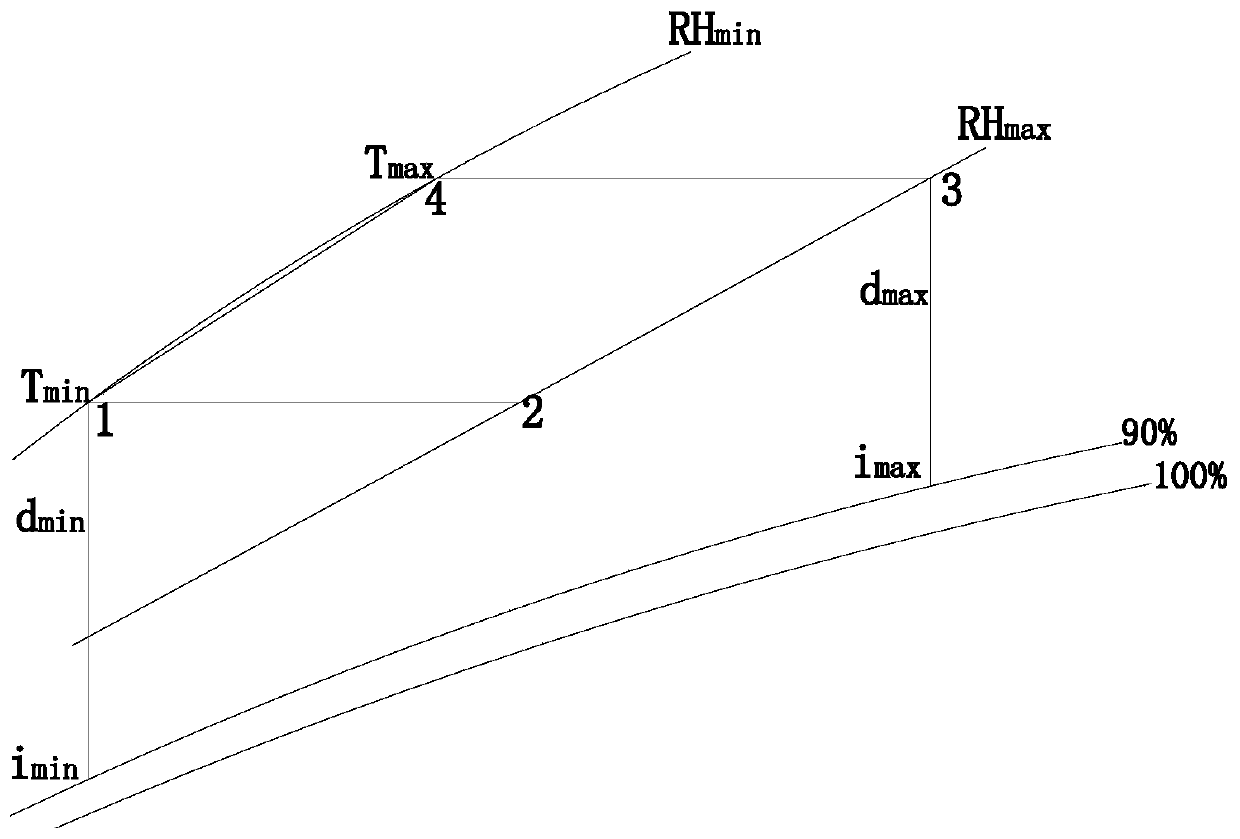

[0041]Since the meteorological parameters outside the workshop vary greatly, the dew point automatic control energy-saving strategy of the textile air-conditioning system in the present invention is divided into three control modes: winter, transitional season and summer according to the meteorological parameters outside the workshop:

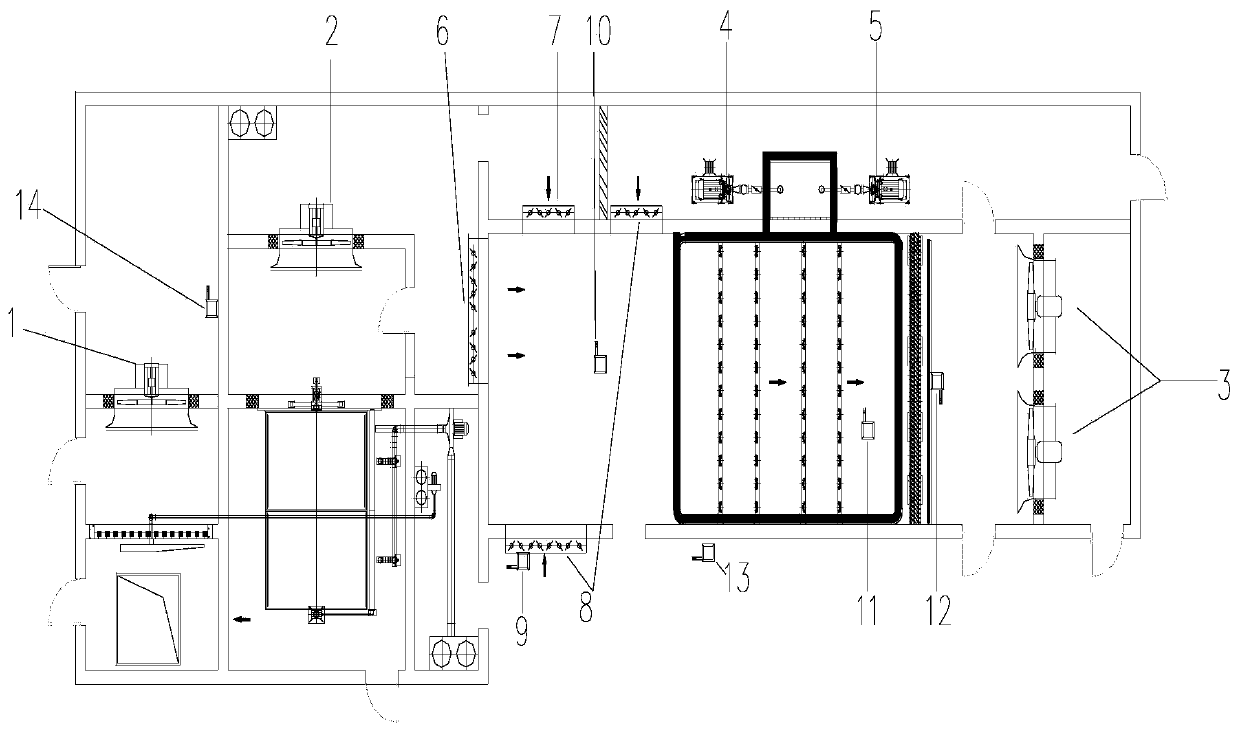

[0042] When the PLC control system is powered on, each device of the air-conditioning system performs an initial assignment, fresh air temperature and humidity sensor 9, mixing point temperature and humidity sensor 10, water temperature sensor 11 in the return pool of the spray room, dew point temperature and humidity sensor 12, and workshop temperature and humidity sensor 13 , The process return air temperature and humidity sensor 14 starts to return the parameters collected in real time to the PLC control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com