Vacuum drier suitable for drying positive electrode material of lithium ion battery and application method thereof

A vacuum dryer and lithium-ion battery technology, applied in the direction of drying solid materials without heating, drying solid materials, non-progressive dryers, etc., can solve the problems of long drying time and poor stirring uniformity, and achieve improved drying The effect of improving efficiency, shortening drying time, and improving the uniformity of stirring and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

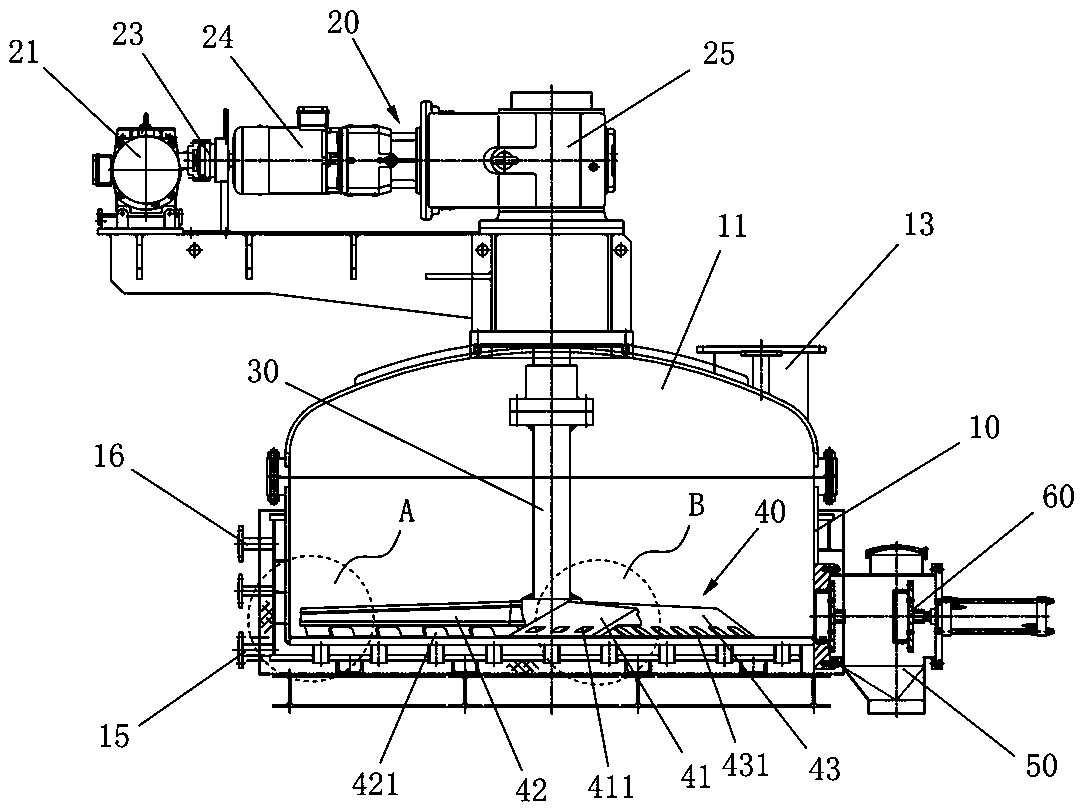

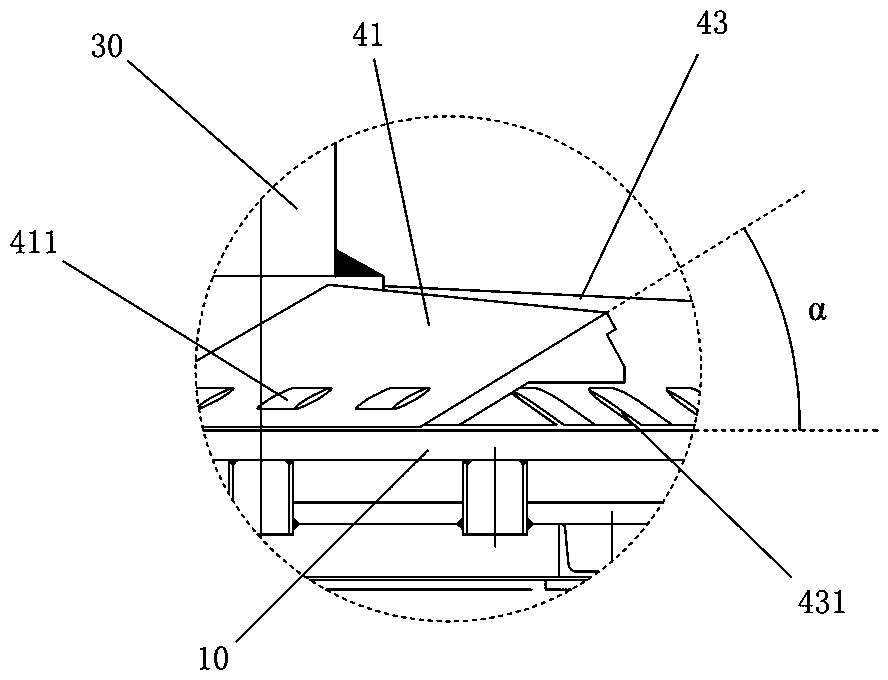

[0055] see Figure 1 to Figure 8 , an embodiment of the vacuum dryer suitable for drying lithium-ion battery positive electrode materials of the present invention, the vacuum dryer includes a cylinder body 10, an upper cover 11 is provided above the cylinder body 10, and a vacuum pumping device is provided on the upper cover 11. Inlet 12, feed inlet 13 and manhole 14, the outside of the cylinder 10 is provided with a jacket, and the jacket is provided with a heating medium inlet 15 and a heating medium outlet 16 (the heating medium is steam or heat transfer oil). Cylinder 10 is provided with stirring device, and this stirring device comprises stirring drive mechanism 20, and the output end of stirring drive mechanism 20 is connected with a stirring shaft 30, and this stirring shaft 30 stretches in the cylinder body 10, and at the lower end of stirring shaft 30 A stirring paddle 40 is installed. The stirring paddle 40 includes a first stirring paddle 41 , a second stirring pad...

Embodiment 2

[0072] see Figure 9 to Figure 12 , an embodiment of the vacuum dryer suitable for drying lithium-ion battery cathode materials of the present invention. The main structure of this vacuum drier is the same as that of the vacuum drier of embodiment 1. Compared with Embodiment 1, the main difference of the vacuum dryer in this embodiment is that the vacuum dryer also includes a discharge cooling device, which includes a cooling furnace body 100 and a cooling and stirring device 102 . Wherein, the cooling furnace body 100 is provided with a cooling feed port 101 communicated with the blanking chamber 50, and the cooling feed port 101 communicates with the furnace cavity of the cooling furnace body 100; the cooling stirring device 102 is installed on the cooling furnace body 100, It is used to stir and turn the materials in the cooling furnace body 100; There are a cooling medium inlet 104 and a cooling medium outlet 105 respectively communicating with the inside of the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com