A high-speed, high-shear, and high-dispersion two-stage extrusion granulation equipment

A technology of two-stage extrusion and granulation equipment, which is applied in the field of modified plastic particles and two-stage extrusion and granulation equipment. It can solve the problems of uniform mixing and dispersion of materials, and that the speed and torque cannot be improved well, so as to reduce water content. High efficiency, improve the uniformity of mixing and dispersion, and the effect of dense, smooth and full material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

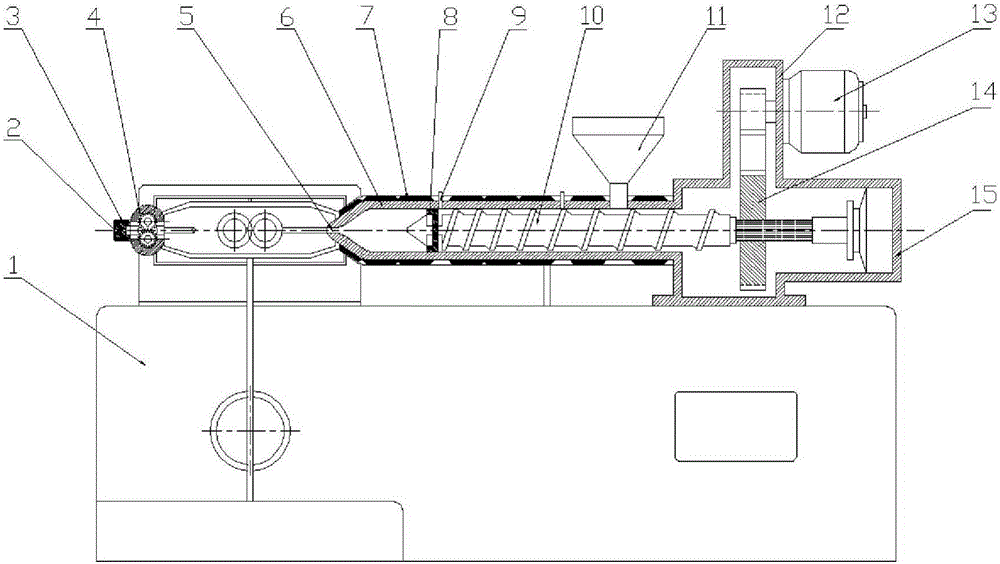

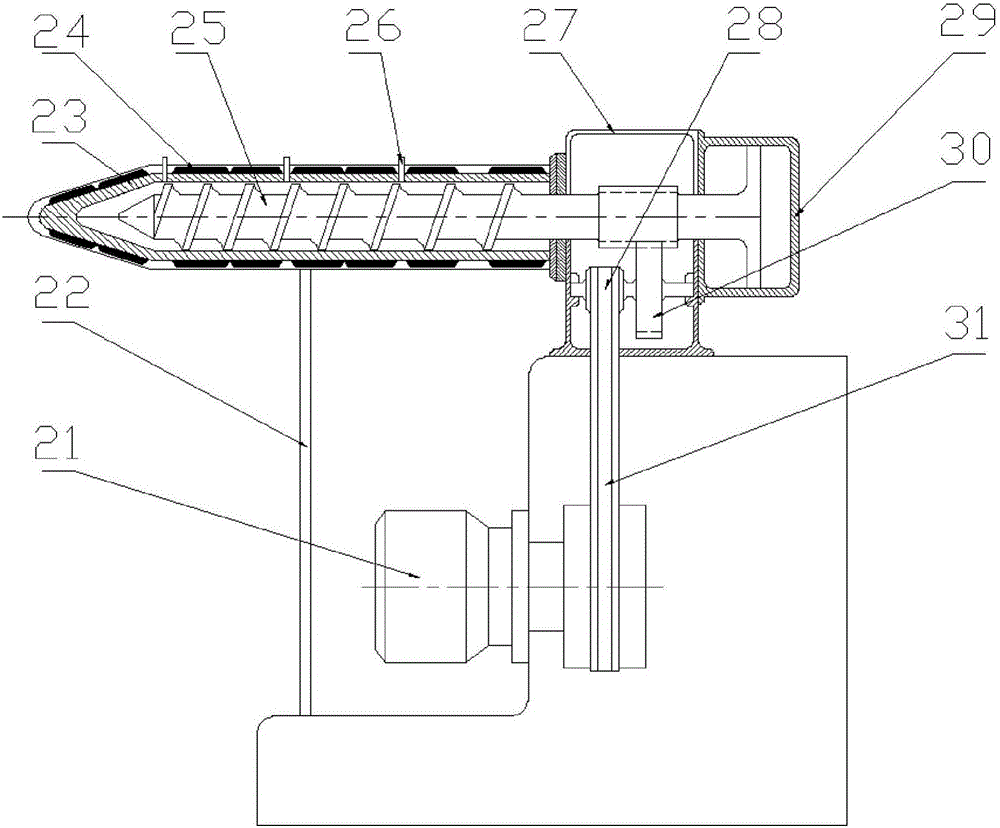

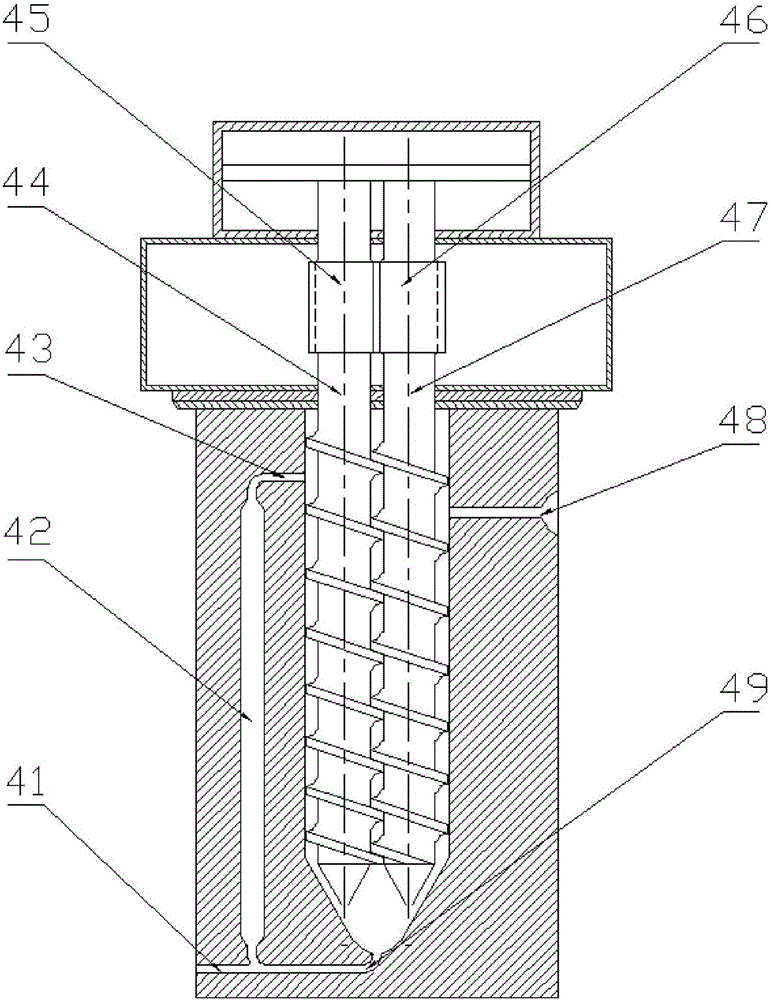

[0023] Such as figure 1 , figure 2 , image 3 As shown, a high-speed, high-shear and high-dispersion two-stage extrusion granulation equipment described in the present invention mainly includes a first-stage single-screw injection system, a second-stage twin-screw deep blending extrusion system, and a cycle blended dispersion system.

[0024]1) The first-stage single-screw injection system is mainly composed of machine base 1, first-stage drive motor 13, first-stage reduction box 12, hydraulic cylinder 15, feeding device 11, screw transmission gear 14, injection single screw 10, check ring 8, injection Machine barrel 6, injection system outlet 5, primary heating system 7, primary exhaust system 9 and other main components. The bottom of the hydraulic cylinder casing is installed on the base 1, the first-stage reduction box 12 is installed on the top of the hydraulic cylinder casing, the first-stage drive motor 13 is installed on the side of the first-stage reduction box 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com