Method for preparing polypropylene/maleic anhydride melt grafting high condensing pre-mixed master batch

The technology of grafting polypropylene and maleic anhydride is applied in the field of preparation of high-concentration premix masterbatch, and can solve the problems of poor stability of the grafting process, fluctuation of the quality of the grafted material, uneven mixing and dispersion of the grafting components, and the like. Achieve stable graft ratio and melt flow rate, improve graft quality, and improve graft process stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

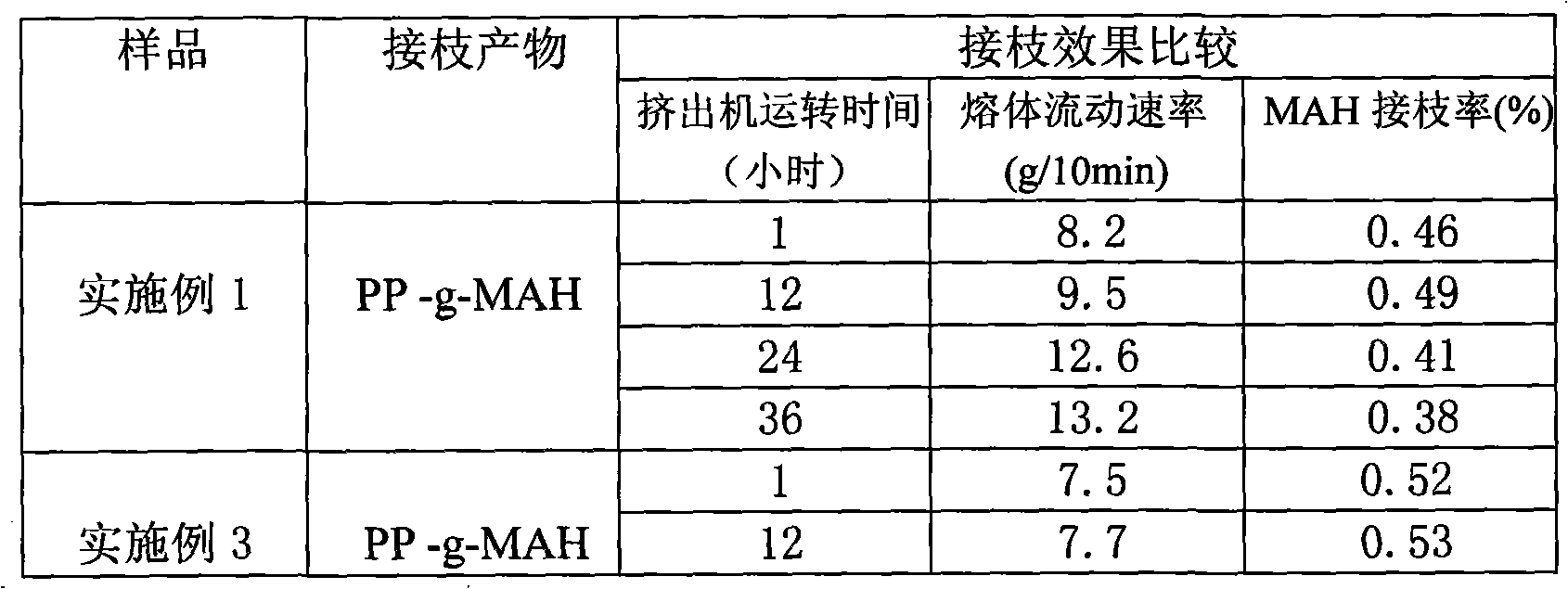

Embodiment 1

[0038] Polypropylene resin (PP, melt flow rate is 3.5g / 10min), maleic anhydride (MAH), initiator 2,5-dimethyl-2,5 bis-tert-butylperoxyhexane (TX101), Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester (antioxidant 1010) and divinylbenzene (DVB) are mixed uniformly in a high-speed disperser, and its formula is as follows : 100 parts PP, 1.2 parts MAH, 0.15 parts TX101, 0.3 parts antioxidant 1010, 0.5 parts DVB.

[0039] The preparation process is as follows: 100 parts of PP, 1.2 parts of MAH, 0.15 parts of initiator TX101, 0.3 parts of antioxidant 1010, and 0.5 parts of DVB are weighed according to the proportion, added to a high-speed disperser and mixed evenly, and then added to a twin-screw extruder The temperature of each section of the twin-screw extruder is 150°C in zone I, 180°C in zone II, 200°C in zone III, 210°C in zone IV, and 210°C in zone V. The head temperature is 210°C, the feeding screw speed is 30r / min, and the host screw speed ...

Embodiment 2

[0041] Dissolve and mix initiator TX101 and divinylbenzene (DVB) in a certain proportion, and mix maleic anhydride and antioxidant 1010 in a high-speed disperser in a certain proportion. Add ethylene / octene copolymer (POE, melting point 70°C, melt flow rate 10g / 10min) from the main feed inlet of the twin-screw extruder, and use a weight-loss electronic metering feeding device to feed maleic anhydride / antioxidant The mixture of agent 1010 is continuously added from the side feed port of the twin-screw extruder mixing section, and the initiator / divinylbenzene mixed solution is continuously injected from the lower feed port of the twin-screw extruder mixing section through a high-pressure metering pump. Each component is forced to disperse and mix in the extruder, and is wrapped by molten POE. The extrudate is cooled and pelletized to obtain a premixed masterbatch. The composition of the premix masterbatch is: 100 parts of POE, 12 parts of MAH, 1.5 parts of TX101, 5.0 parts of D...

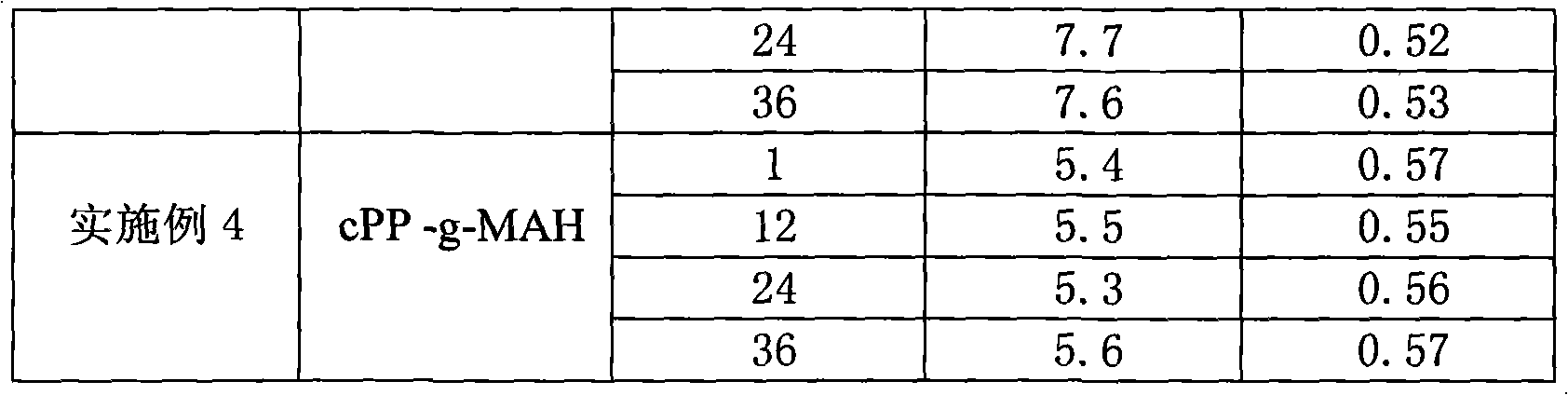

Embodiment 3

[0044] The pre-mixed masterbatch prepared in Example 2 and polypropylene homopolymer resin (PP, melt flow rate 3.5g / 10min) are uniformly mixed in a high-speed disperser according to a certain proportion, and then melted on a twin-screw extruder. branch to prepare maleic anhydride grafted polypropylene products. The preparation process is as follows: Add 90 parts of PP and 10 parts of premixed masterbatch into a high-speed disperser and mix them. Since the two materials are granular, they are easy to mix evenly. Put the mixed material into the twin-screw extruder for melt extrusion and grafting. The temperature of each section of the twin-screw extruder is: the temperature in zone I is 150°C, the temperature in zone II is 180°C, the temperature in zone III is 200°C, and the temperature in zone IV 210°C, V zone temperature 210°C, head temperature 210°C; feeding screw speed 30r / min, host screw speed 150r / min. The residence time of the material in the twin-screw extruder is 1.2 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com