Preparation process of duck egg powder

A preparation process, duck egg technology, applied in skin care preparations, medical preparations containing active ingredients, cosmetic preparations, etc., can solve the problem of poor powder dispersion and mixing uniformity, powder agglomeration and agglomeration, and spreadability To improve the uniformity of dispersion and mixing, avoid agglomeration and agglomeration, and improve the spreading performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

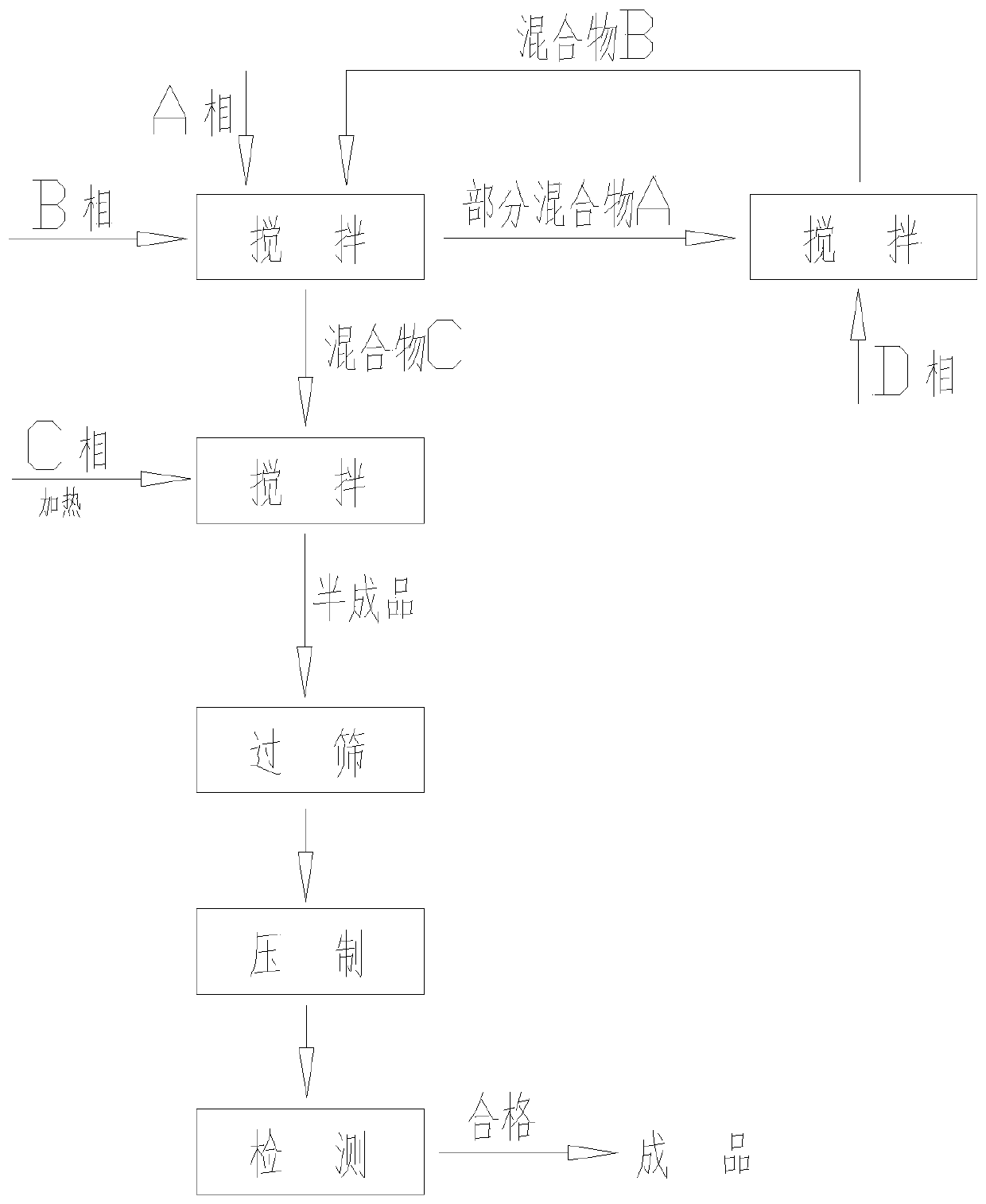

Image

Examples

Embodiment 1

[0027] A kind of preparation technology of duck egg powder, comprises the following steps:

[0028] Step 1: Weigh 92% of phase A, 2.3% of phase B, 5% of phase C, and 0.7% of phase D according to mass percentage, dissolve phase D at room temperature, and sterilize for 25 minutes, and pulverize phase B by airflow, and set aside;

[0029] Step 2: Mix phase A and phase B with vibration and stirring for 1 min to form mixture A, the vibration frequency is 10HZ, and the frequency of vibration and stirring is 2 times;

[0030] Step 3: Mix part A of the mixture in step 2 with phase D to form mixture B, pass through a sieve once with a mesh size of 70 mesh, then add mixture B to the remaining mixture A in step 2 and vibrate and stir for 1.5 minutes to form mixture C , the vibration frequency is 10HZ, and the frequency of vibration and stirring is 2 times;

[0031] Step 4: Heat and dissolve phase C at 65°C, then add phase C to the mixture C in step 3 and vibrate and stir for 2 minutes t...

Embodiment 2

[0036] A kind of preparation technology of duck egg powder, comprises the following steps:

[0037] Step 1: Weigh 93% of phase A, 2.7% of phase B, 4% of phase C, and 0.3% of phase D according to the mass percentage, dissolve phase D at room temperature, and sterilize for 30 minutes, and pulverize phase B by airflow, and set aside;

[0038] Step 2: Mix phase A and phase B with vibration and stirring for 2 minutes to form mixture A, the vibration frequency is 12HZ, and the frequency of vibration and stirring is 3 times;

[0039] Step 3: Mix part A of the mixture in step 2 with phase D to form mixture B, pass through a sieve once with a mesh size of 80 mesh, then add mixture B to the remaining mixture A in step 2 and vibrate and stir for 2 minutes to form mixture C, The vibration frequency is 12HZ, and the frequency of vibration and stirring is 3 times;

[0040] Step 4: Heat and dissolve phase C at 70°C, then add phase C to the mixture C in step 3 and vibrate and stir for 3 minu...

Embodiment 3

[0045] A kind of preparation technology of duck egg powder, comprises the following steps:

[0046] Step 1: Weigh 94% of phase A, 3.1% of phase B, 2% of phase C, and 0.9% of phase D according to the mass percentage, dissolve phase D at room temperature, and sterilize for 35 minutes, crush phase B by airflow, and set aside;

[0047] Step 2: Mix phase A and phase B with vibration and stirring for 2.5 minutes to form mixture A, the vibration frequency is 14HZ, and the frequency of vibration and stirring is 4 times;

[0048] Step 3: Mix part A of the mixture in step 2 with phase D to form mixture B, pass through a sieve once with a mesh size of 90 mesh, then add mixture B to the remaining mixture A in step 2 and vibrate and stir for 2.5 minutes to form mixture C , the vibration frequency is 14HZ, and the frequency of vibration stirring is 4 times;

[0049] Step 4: Heat and dissolve phase C at 75°C, then add phase C to the mixture C in step 3 and vibrate and stir for 4 minutes to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com