Engineering construction supervision quality acceptance measurement system and method

A quality and supervision technology, applied in measuring devices, mechanical equipment, mechanical measuring devices, etc., can solve the problems of easy error, human resource consumption, low measurement accuracy, etc., and achieve the effect of improving accuracy and reliability and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

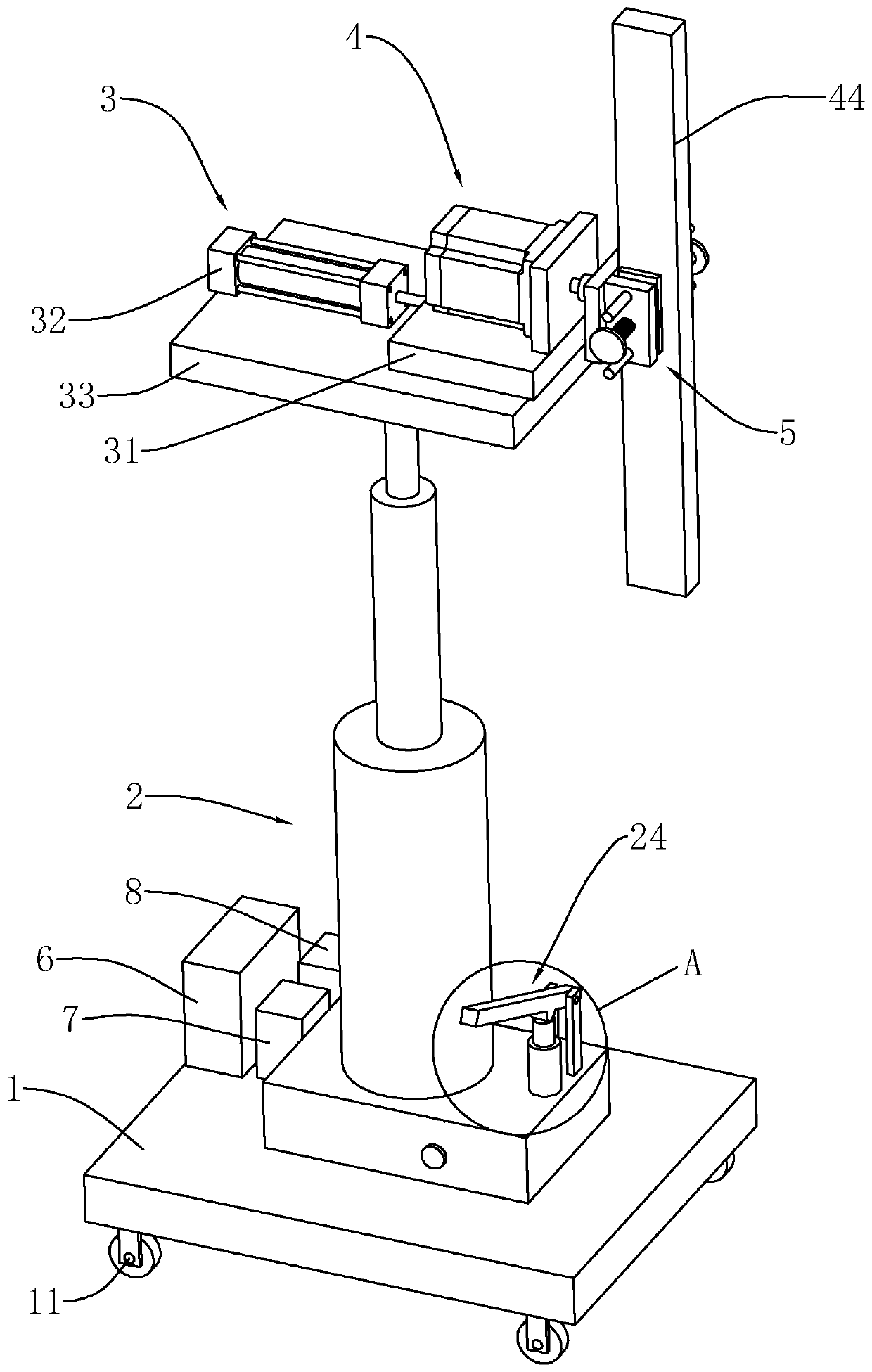

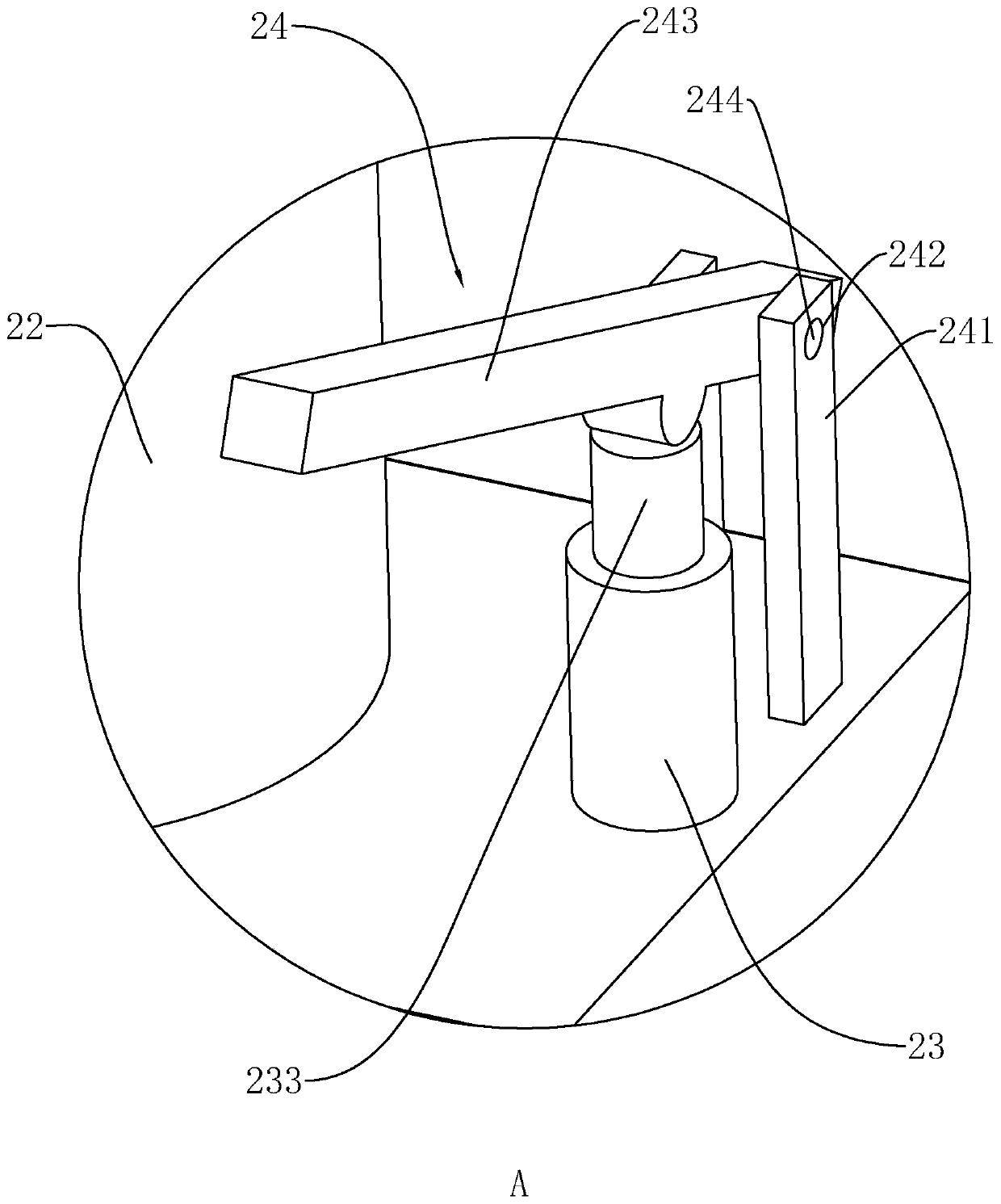

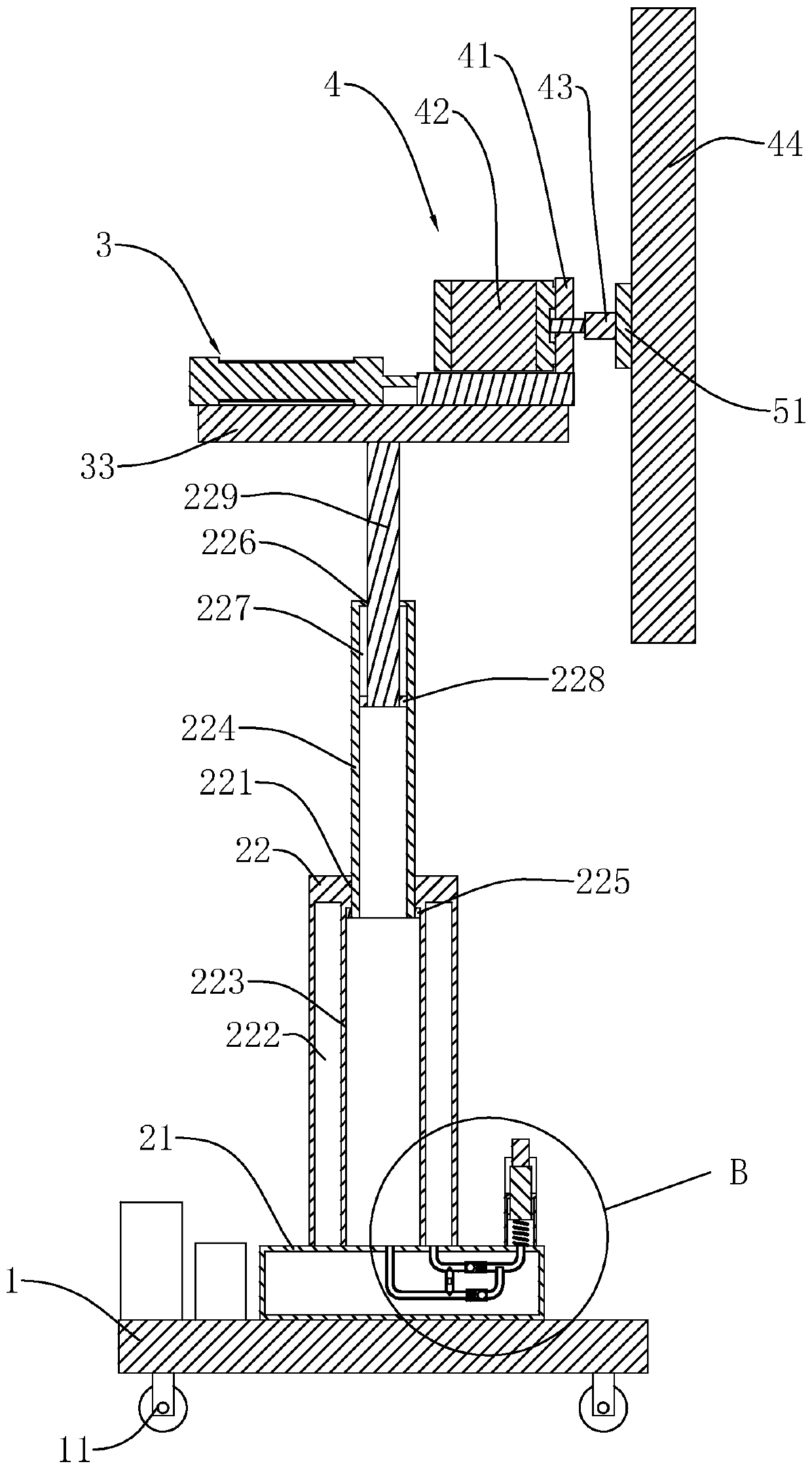

[0040] This embodiment discloses an actual measurement and measurement system for project construction supervision quality acceptance, such as figure 1 with Figure 5 As shown, it includes a bottom plate 1, a vertical movement mechanism 2 is arranged on the bottom plate 1, a horizontal movement mechanism 3 is arranged on the vertical movement mechanism 2, and a detection mechanism 4 is arranged on the horizontal movement mechanism 3. The horizontal movement mechanism 3 includes a slide plate 31 and an air cylinder 32 . The detection mechanism 4 includes a fixed seat 41 fixedly connected to the slide plate 31, a stepper motor 42 is fixedly connected to one end of the fixed seat 41 facing the cylinder 32, and an operating shaft 43 is fixedly connected to the output end of the stepping motor 42, and the operating shaft 43 is far away from the stepper motor. One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com