Machine vision-based reed quality detection method

A quality inspection method and machine vision technology, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problem that there is no reed quality inspection method and device, it is not suitable for repeated use, and it is impossible to obtain accurate reed reeds total number of teeth etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

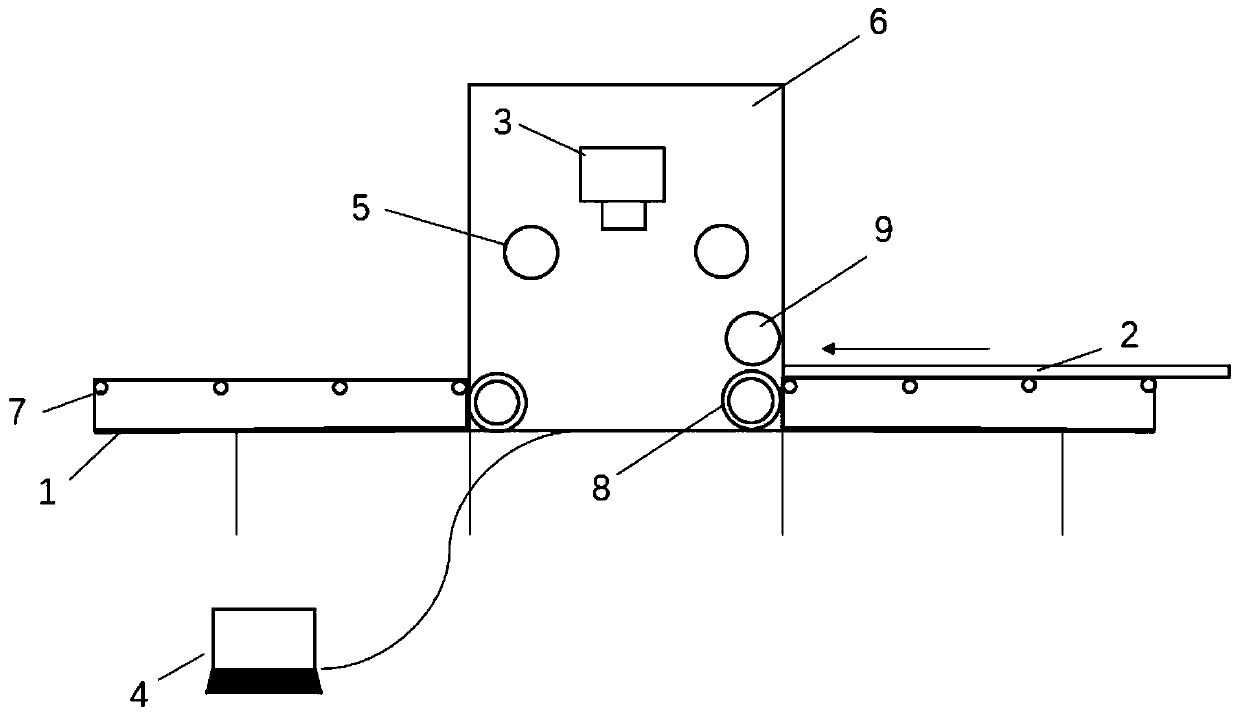

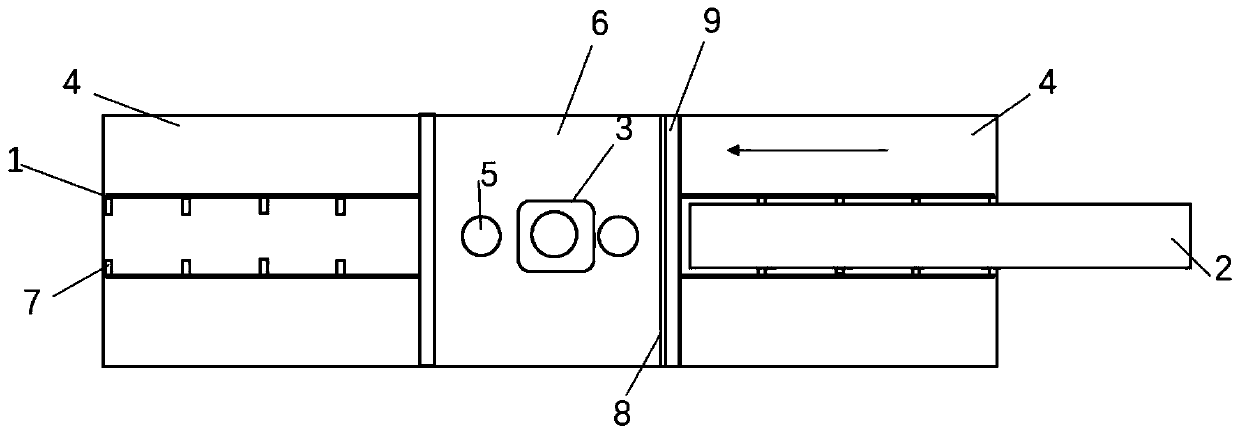

[0036] In order to illustrate the embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the drawings that are required in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only simplified diagrams of some devices of the present invention. For those skilled in the art, they can intuitively understand the operation process of the device of the present invention and It can be operated on the computer.

[0037] The embodiment of the present invention provides a kind of reed quality detection method based on machine vision, comprises the following steps:

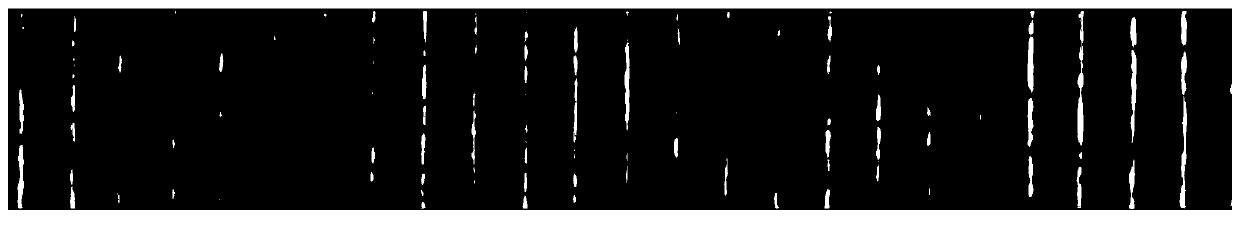

[0038] (1) use figure 1 and figure 2 The device collects reed images, the image size is 1292×256 pixels, and the resolution is 100 pixels / mm. The acquisition frame rate is set so that the overlapping area between adjacent images accounts for 50% of the original image. The collected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com