A kind of indentation test device and test method

A test method and technology of test device, which are applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problem of long heating/cooling time period, high test cost, displacement measurement value and real value deviation and other problems to achieve the effect of shortening the test cycle, improving the test efficiency and reducing the test cost

Active Publication Date: 2022-08-05

EAST CHINA UNIV OF SCI & TECH

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Through research, it is found that the existing macro-indentation devices at home and abroad are all within a single temperature range, normal temperature, low temperature or high temperature (Zhang T, Wang S, Wang W. et al. Results in Physics, 2018, 8: 716- 727; Qu Z, Yu M, LiuY, et al. Rev Sci Instrum, 2017, 88(4): 045102; Wei Zhongkun, et al., Mechanical Engineering Materials, 2016, 40(1): 32-34), no simultaneous integration High and low temperature indentation devices have been developed to characterize the mechanical properties of various materials at different temperatures; at the same time, the current indentation devices are all single indenters, and only one sample can be made in one experiment, especially in high / low temperature Low-temperature indentation test, the heating / cooling time period is long, and only one sample can be made at a time, which will lead to long time consumption, low efficiency, and high test cost, which cannot meet the urgent requirements of quickly testing the mechanical properties of new structural materials and shortening the research and development cycle; finally, The contact zero point of existing indentation test devices is mostly determined by preloading, and then indirectly and roughly estimated by curve fitting and extrapolation methods or by measuring the first increase in test force or contact stiffness This traditional indirect method cannot directly and accurately determine the zero point of contact between the indenter and the sample before the experiment, resulting in a deviation between the measured value of the displacement and the actual value, which affects the test results the accuracy of

[0006] In view of the problems that existing indentation equipment cannot directly determine the contact zero point, the measurement efficiency is low, and the measurement in a wide temperature range cannot be realized, there is an urgent need in this field to develop a method that can directly determine the contact zero point and can measure material mechanics in a wide temperature range. High-throughput indentation testing device for performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0124] In this embodiment, the high temperature indentation test of the same batch of new metal materials with different compositions is carried out at the same temperature, and the advantages and disadvantages of their high temperature fracture properties are compared, which is used to screen out materials with good high temperature fracture mechanical properties.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

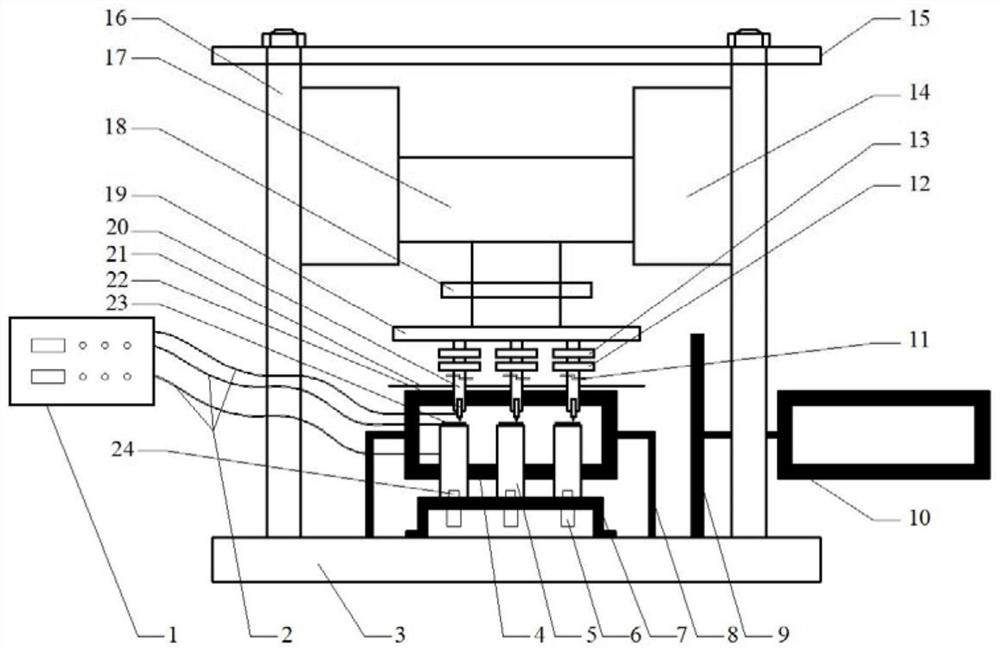

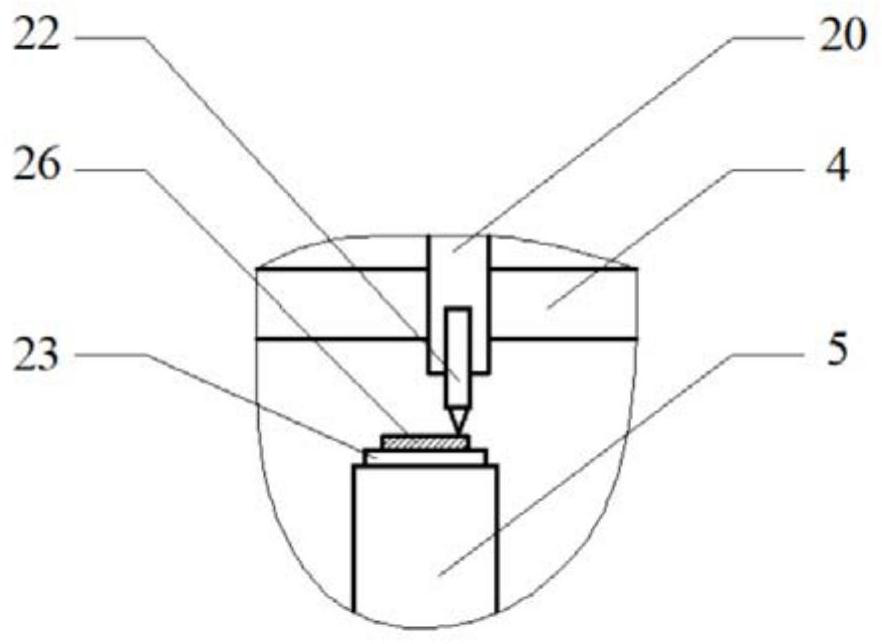

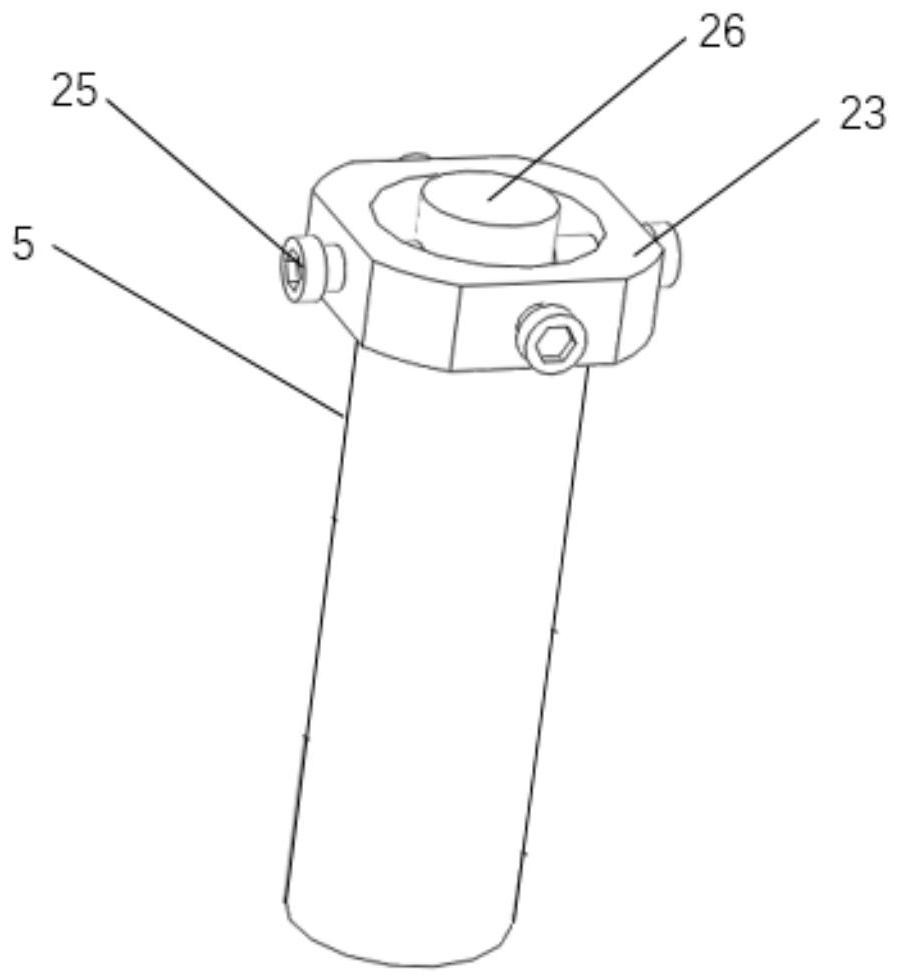

The invention provides a novel high-flux and wide-temperature range indentation testing device and testing method that can measure various mechanical properties of materials (such as elastic modulus, yield strength, tensile strength, fracture toughness, creep performance, etc.). . The device can directly determine the contact zero point between the indenter and the sample through fine-tuning, and can provide a temperature environment from ‑253℃ to 1000℃, and can perform multiple sets of indentation tests at the same temperature environment at the same time. The device includes a base, a sample platform, a force application system, a distance adjustment system, a feedback control system, a measurement system, a temperature control system and / or a thermal insulation system. The invention solves the problem that the existing indentation device cannot directly determine the contact zero point between the indenter and the sample; at the same time, it solves the problem that the existing device cannot carry out the multi-head indentation test at the same time in the same test environment, and provides an The device and test method for indentation testing of multiple samples of the same or different sizes under working conditions; the indentation test in a wide temperature range can also be realized through the conversion of the temperature environment box.

Description

technical field [0001] The invention relates to an indentation testing device and an indentation testing method, in particular to a high-flux and wide-temperature range indentation testing device for testing macroscopic mechanical properties, which can be used for rapid screening of mechanical properties of materials, and belongs to the micro-loss mechanical properties of materials test area. Background technique [0002] In the important industrial fields related to the national economy and people's livelihood, such as energy, chemical industry, transportation and detection, the service environment of related equipment tends to develop in the direction of more extreme temperatures. Commonly used high / low temperature metal materials have been unable to meet the needs of modern industrial development, and new advanced structural materials need to be developed to meet the higher requirements for mechanical properties of materials in the industrial field. [0003] The "Materia...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/18G01N3/02

CPCG01N3/18G01N3/02G01N2203/0003G01N2203/0019G01N2203/0067G01N2203/0094G01N2203/0078G01N2203/0206G01N2203/0226G01N2203/0228G01N2203/0252G01N2203/0482G01N2203/0676G01N2203/0682

Inventor 谈建平朱文波涂善东李思宽王卫泽

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com