Automatic dispensing method and device based on machine vision

An automatic dispensing and machine vision technology, applied in the field of automation, can solve the problems of a large number of human participation and the inability to intelligently dispensing various workpieces, so as to reduce the manpower load, improve the smoothness of production, and improve the ability of automatic extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

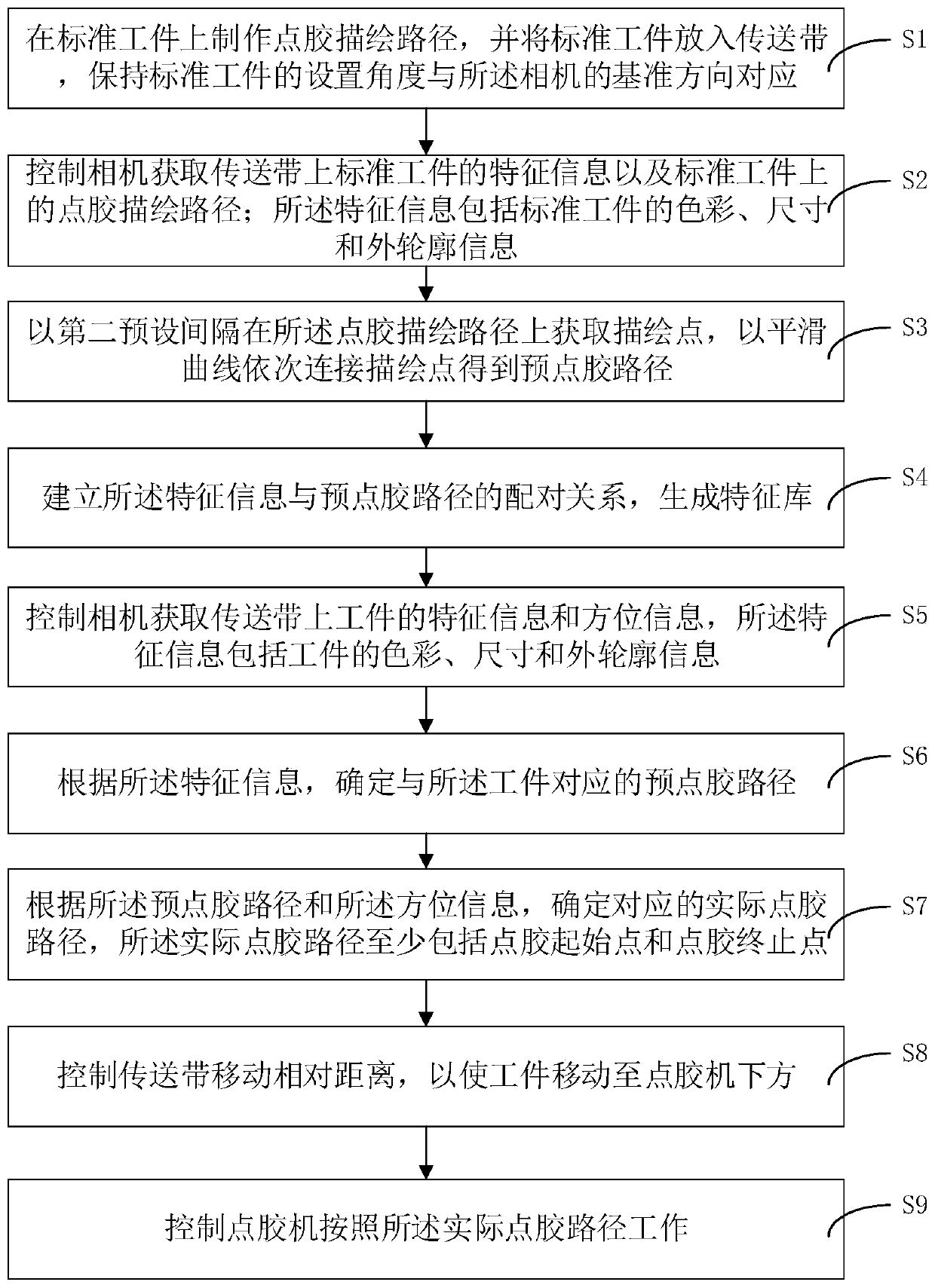

[0059] Please refer to figure 1 As shown, the embodiment of the present invention provides an automatic dispensing method based on machine vision, including:

[0060] S1, make a dispensing and tracing path on the standard workpiece, put the standard workpiece into the conveyor belt, and keep the setting angle of the standard workpiece corresponding to the reference direction of the camera;

[0061] The standard workpiece is used to provide a pre-dispensing path for subsequent workpieces with the same feature information. The dispensing drawing path can be a stroke path or a path formed by punching. In this embodiment, the camera is a line array camera.

[0062] S2, controlling the camera to obtain the characteristic information of the standard workpiece on the conveyor belt and the dispensing and drawing path on the standard workpiece; the characteristic information includes the color, size and outer contour information of the standard workpiece;

[0063] The color of the sta...

no. 2 example

[0118] An embodiment of the present invention provides an automatic dispensing device based on machine vision, including:

[0119] The acquisition module is connected with the first determination module, and is used to control the camera to acquire the feature information and orientation information of the workpiece on the conveyor belt, the feature information including the color, size and outline information of the workpiece;

[0120] The first determination module is connected with the second determination module, and is used to determine the pre-dispensing path corresponding to the workpiece according to the feature information;

[0121] The second determination module is connected with the first control module, and is used to determine the corresponding actual dispensing path according to the pre-dispensing path and the orientation information, and the actual dispensing path includes at least a dispensing start point and a dispensing point termination point;

[0122] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com