Virtual debugging method of automobile production line based on digital factory

A technology of automobile production line and debugging method, which is applied in the field of virtual debugging of automobile production line, can solve the problems of unpredictable debugging cycle on site and prolonging the project cycle, so as to shorten the project cycle and cost, reduce the debugging time, and verify the rationality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

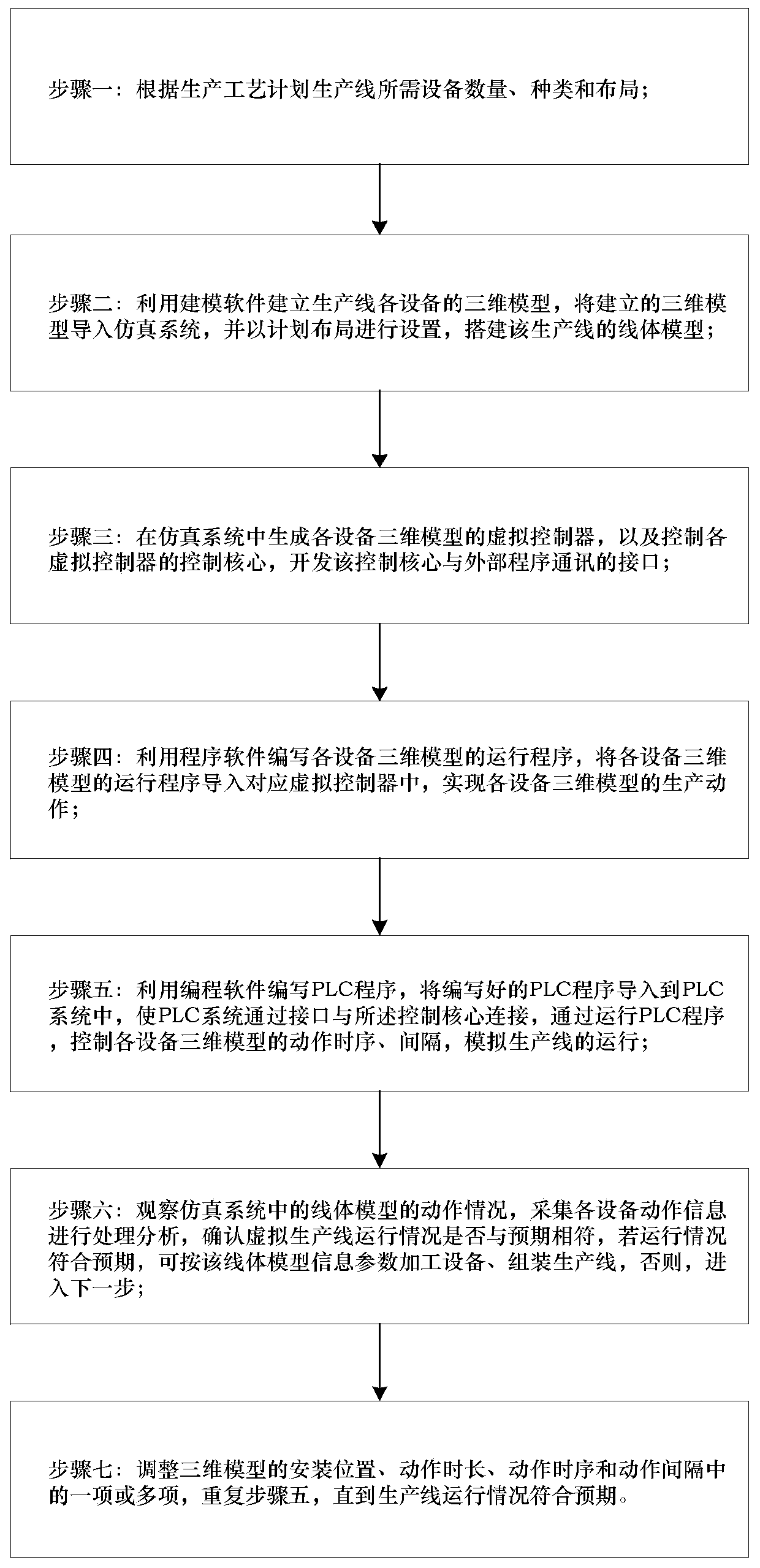

[0015] Such as figure 1 As shown, a virtual commissioning method of an automobile production line based on a digital factory includes the following steps:

[0016] Step 1: Plan the quantity, type and layout of equipment required for the production line according to the production process;

[0017] Step 2: Use modeling software to establish a 3D model of each equipment in the production line, import the established 3D model into the simulation system, and set it up with the planned layout to build a line body model of the production line;

[0018] Step 3: Generate the virtual controllers of the three-dimensional models of each device in the simulation system, and the control cores that control each virtual controller, and develop the communication interface between the control core and external programs;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com