Wheel type stop force feedback control method and device and wearable device

A control method and force feedback technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve problems such as failure to reach the required value, damage to the execution of the object to be executed, etc., to achieve quick response, improve on-the-spot immersion, and good The effect of practicality and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

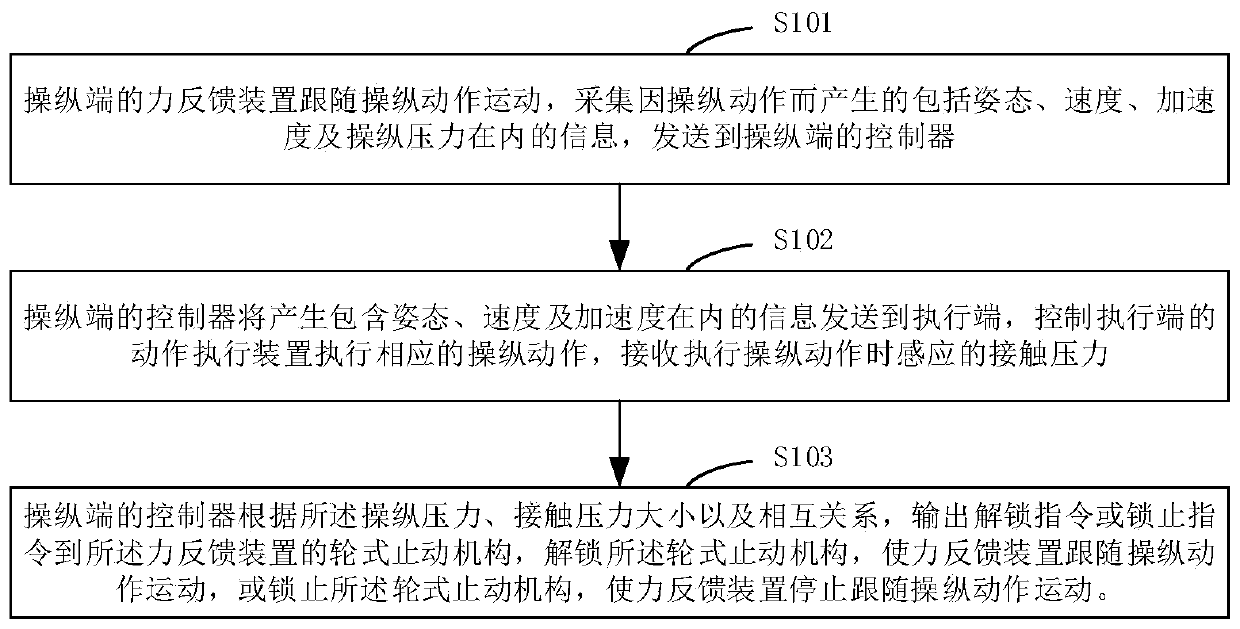

[0042] This embodiment discloses a force feedback control method for a wheel stop, such as figure 1 shown, including the following steps:

[0043] Step S101, the force feedback device at the control end follows the movement of the control action, collects information including posture, velocity, acceleration and control pressure generated by the control action, and sends it to the controller at the control end;

[0044] Step S102, the controller at the manipulation end sends the generated information including attitude, velocity and acceleration to the execution end, controls the action execution device at the execution end to execute the corresponding manipulation action, and receives the contact pressure sensed during the execution of the manipulation action;

[0045] Step S103, the controller at the manipulating end outputs an unlocking command or a locking command to the wheel stop mechanism of the force feedback device according to the manipulating pressure, the magnitude...

Embodiment 2

[0077] This embodiment discloses a joint remote control device based on force feedback, including a manipulation end and an execution end;

[0078] The control end includes a force feedback device and a controller;

[0079] The force feedback device is used to follow the movement of the manipulation action, collect information including attitude, speed, acceleration and manipulation pressure generated by the manipulation action, and send it to the controller at the manipulation end;

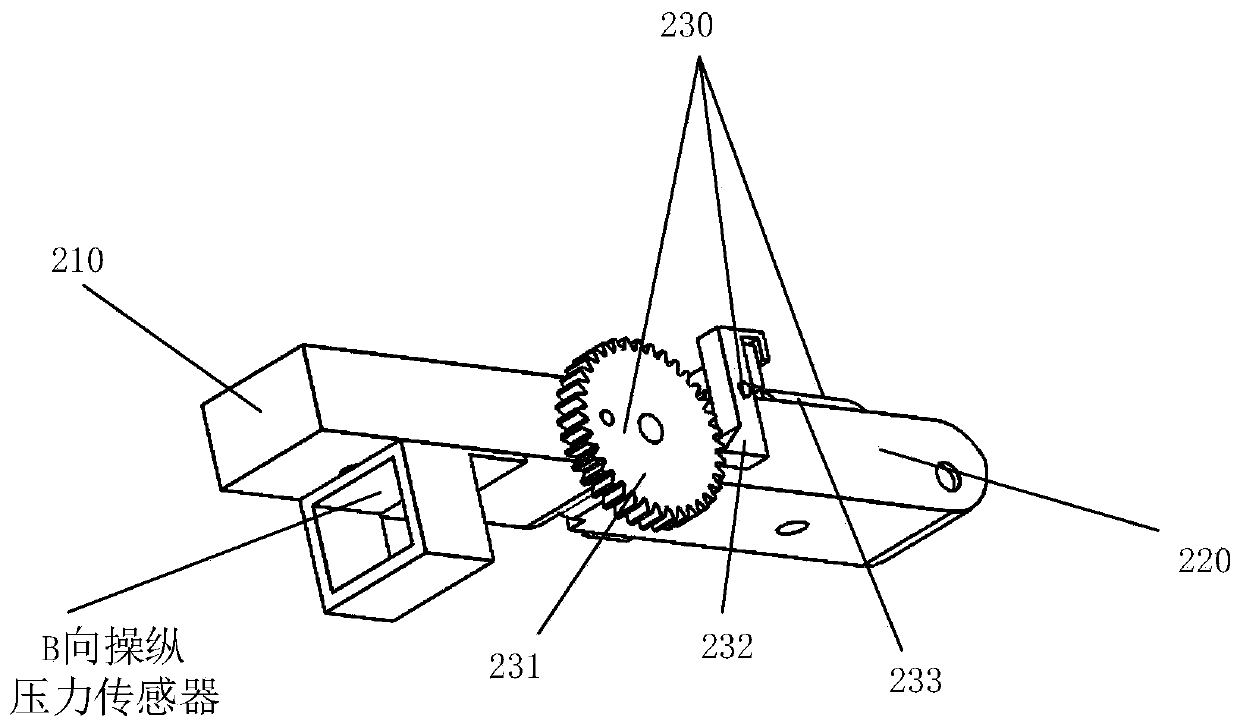

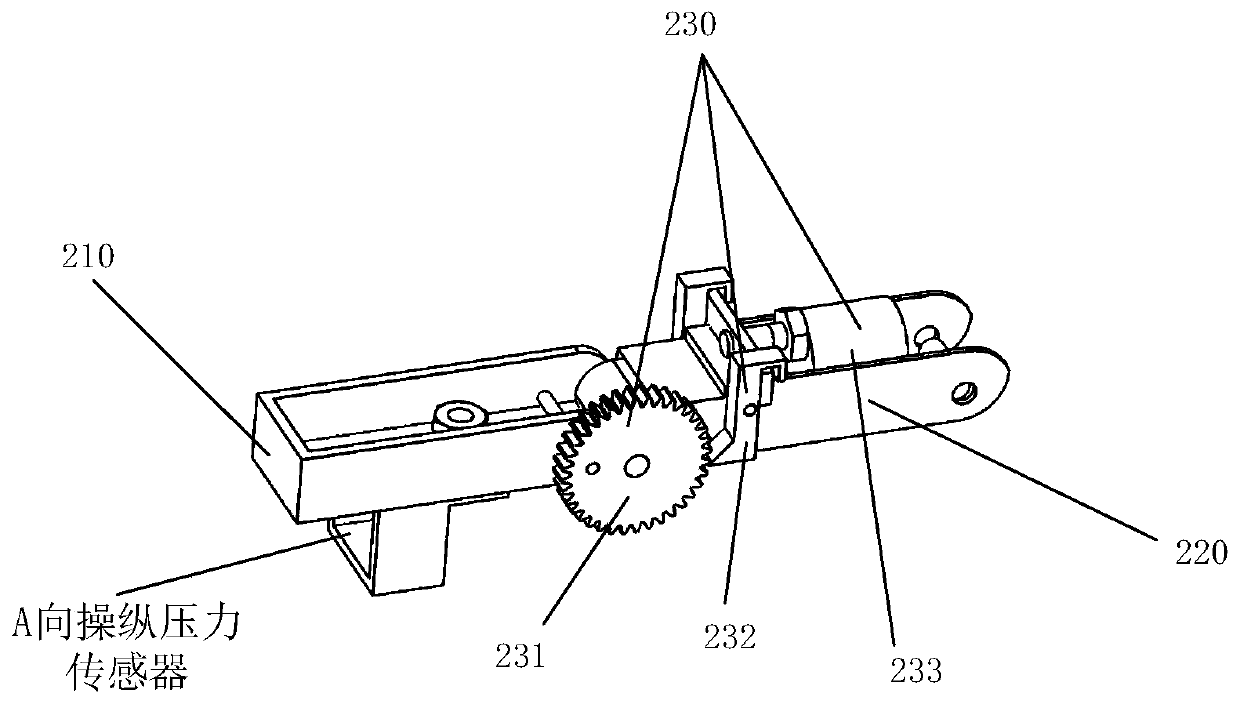

[0080] Preferably, the force feedback device at the control end is composed of connections such as figure 2 or 3;

[0081] The controller is used to send the generated information including posture, velocity and acceleration to the execution end, control the action execution device on the execution end to execute the corresponding manipulation action, and receive the contact pressure sensed when performing the manipulation action; and according to the manipulation pressure , the contact pressu...

Embodiment 3

[0085] This embodiment discloses a wearable remote control device. This embodiment takes the remote control of a robot hand as an example, such as Figure 7 As shown, it is a driving device that can be worn on the palm, and each joint of the driving device includes a force feedback device as in Embodiment 2; all force feedback devices generate the palm movements collected by the driving device, including gestures , speed, acceleration and operating pressure, and send them to the controller of the driving device;

[0086] Such as Figure 7 As shown, it is the driven robot limb, that is, the robot palm. Each joint of the robot palm includes an action execution device as in Embodiment 2; the action sent by the drive device wearable on the palm is executed through the controller, and the feedback Perceived external force.

[0087] When the drive device wearable on the palm controls the driven robot limbs to perform actions, sample the force feedback control method based on the whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com