Magnetron sputtering coating device

A magnetron sputtering coating and equipment technology, applied in the field of magnetron sputtering, can solve the problems of the reduction of high-energy electrons bombarding the substrate, the difficulty of ensuring uniformity and consistency, etc., to achieve expanded utilization efficiency, ideal structure, and reduce investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

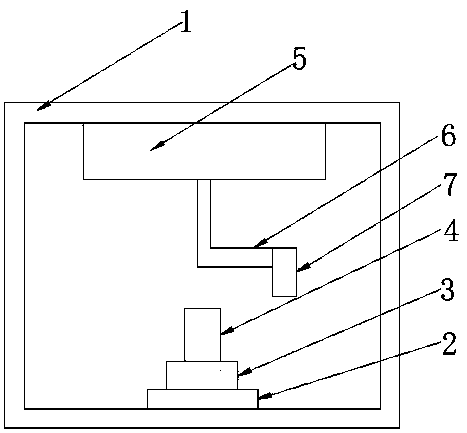

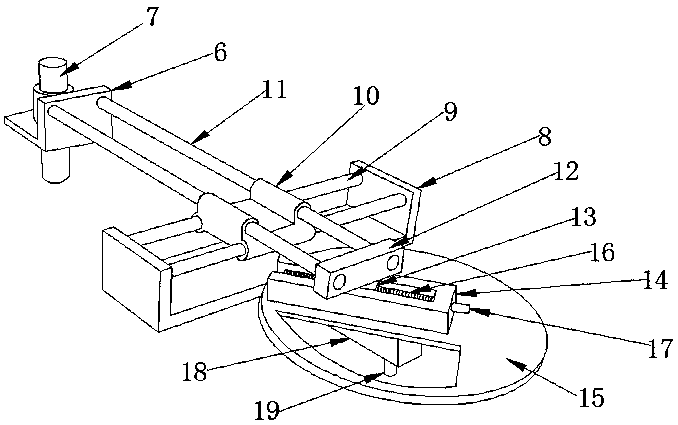

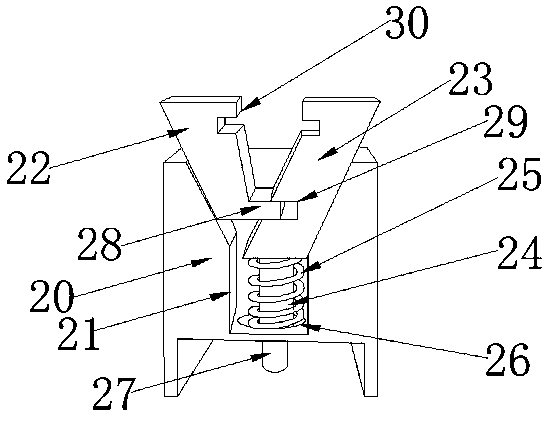

[0022] Embodiment one, such as Figure 1-3 As shown, a magnetron sputtering coating device according to an embodiment of the present invention includes a vacuum chamber 1, a substrate stage 2 is provided at the inner lower end of the vacuum chamber 1, and a target holder is provided at the upper end of the substrate stage 2. 3. The upper end of the target base 3 is provided with a fixing device 4, the inner upper end of the vacuum chamber 1 is provided with a rotating device 5, the lower end of the rotating device 5 is provided with a connecting piece 6, and one end of the connecting piece 6 is provided There is a magnetron target 7, wherein the rotating device 5 includes a fixed frame 8, and the upper end of the fixed frame 8 is connected to the inner upper end of the vacuum chamber 1, and two groups of The fixed rod 9 is provided with a slide plate 10 on the fixed rod 9, and two sets of movable rods 11 are interspersed on both sides of the top of the slide plate 10, and one ...

Embodiment 2

[0023] Embodiment two, such as figure 2 As shown, and, the slide plate 10 has a double-layer structure, two sets of fixed rods 9 penetrate the lower end of the slide plate 10, two sets of movable rods 11 penetrate the upper end of the slide plate 10, and the The fixed rod 9 and the movable rod 11 are perpendicular to each other.

Embodiment 3

[0024] Embodiment three, such as figure 2 As shown, the joints of the screw mandrel 16, the slider 13 and the chute 14 are provided with internal threads matched with the screw mandrel 16, and the lower end of the movable plate 15 is connected to the fixed frame. 8 are fixedly connected by a support frame 18, and a movable shaft 19 is provided at the bottom of the lower end of the movable disk 15, and a drive motor is connected to the lower end of the movable disk 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com