Distributed monocular camera laser measuring device and method for assembling rotation angle of cylindrical parts

A technology of laser measurement and cylindrical parts, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

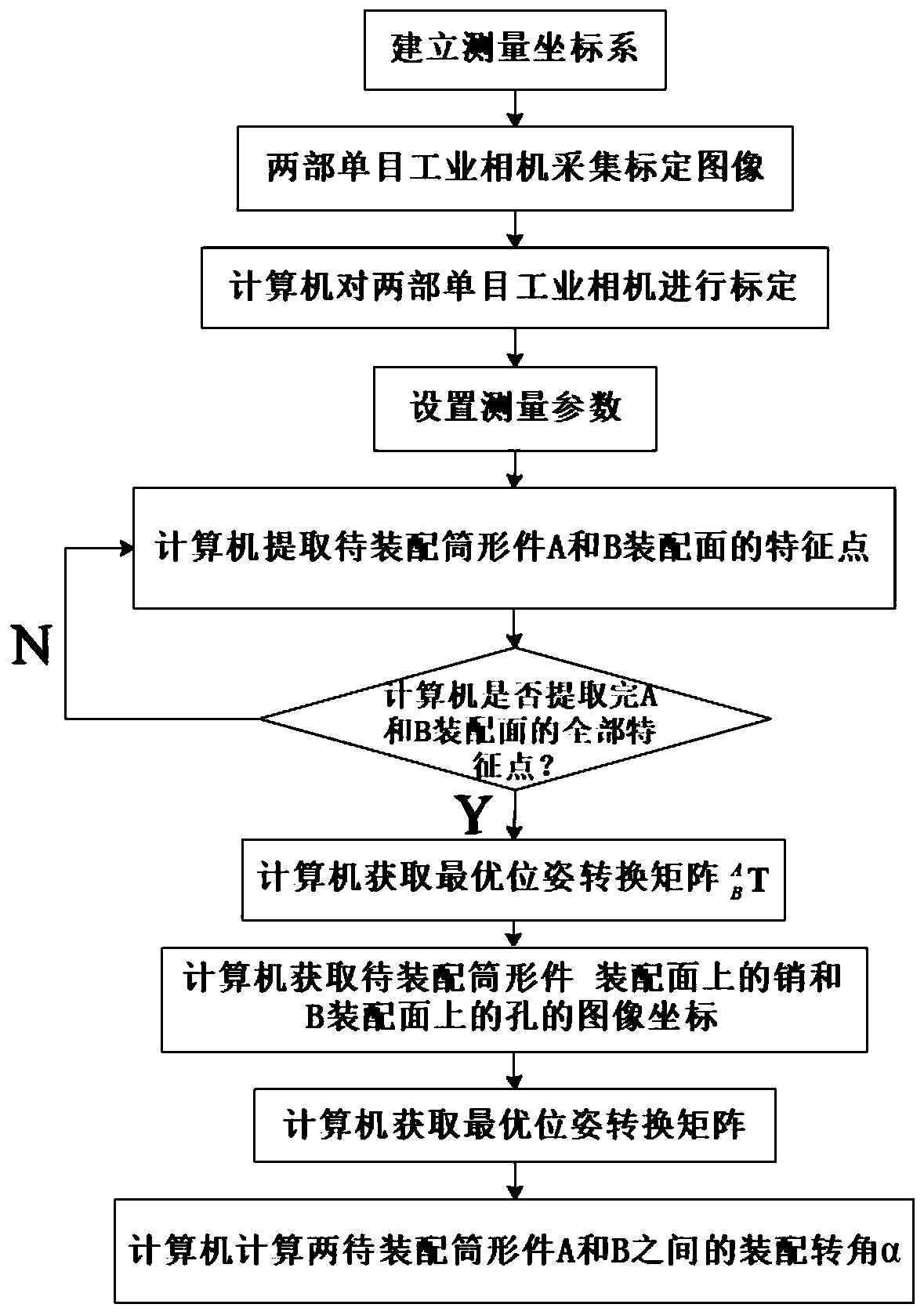

[0059] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail:

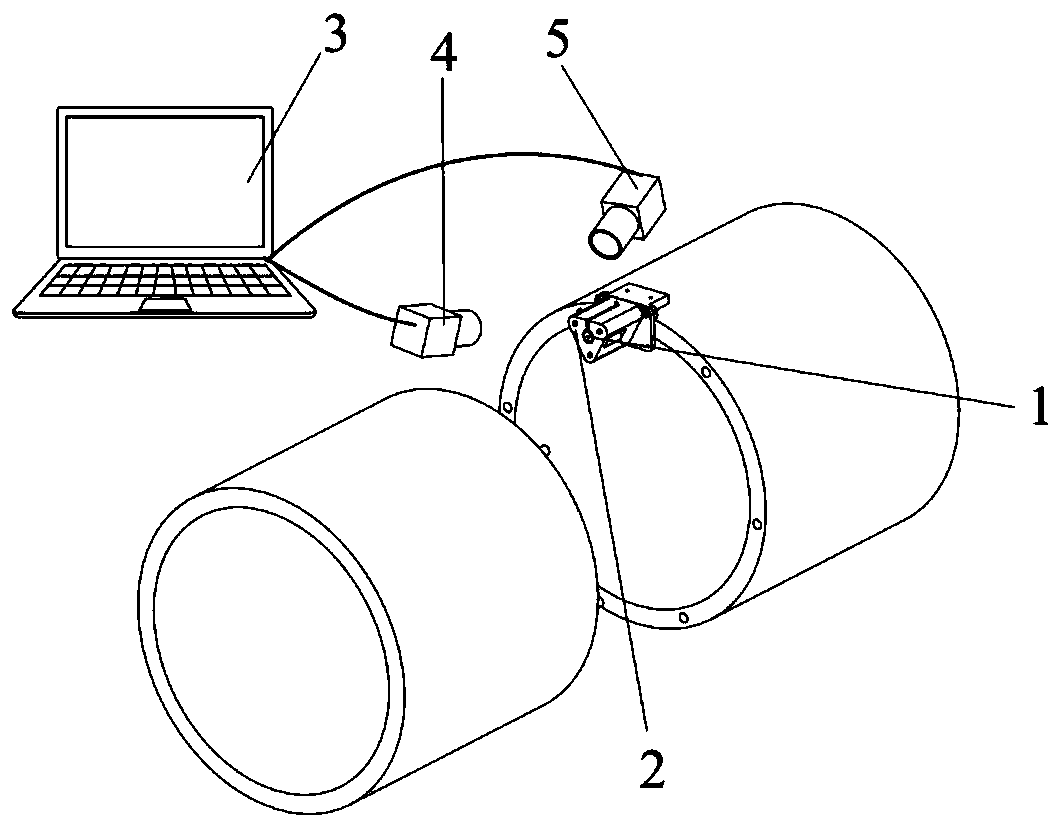

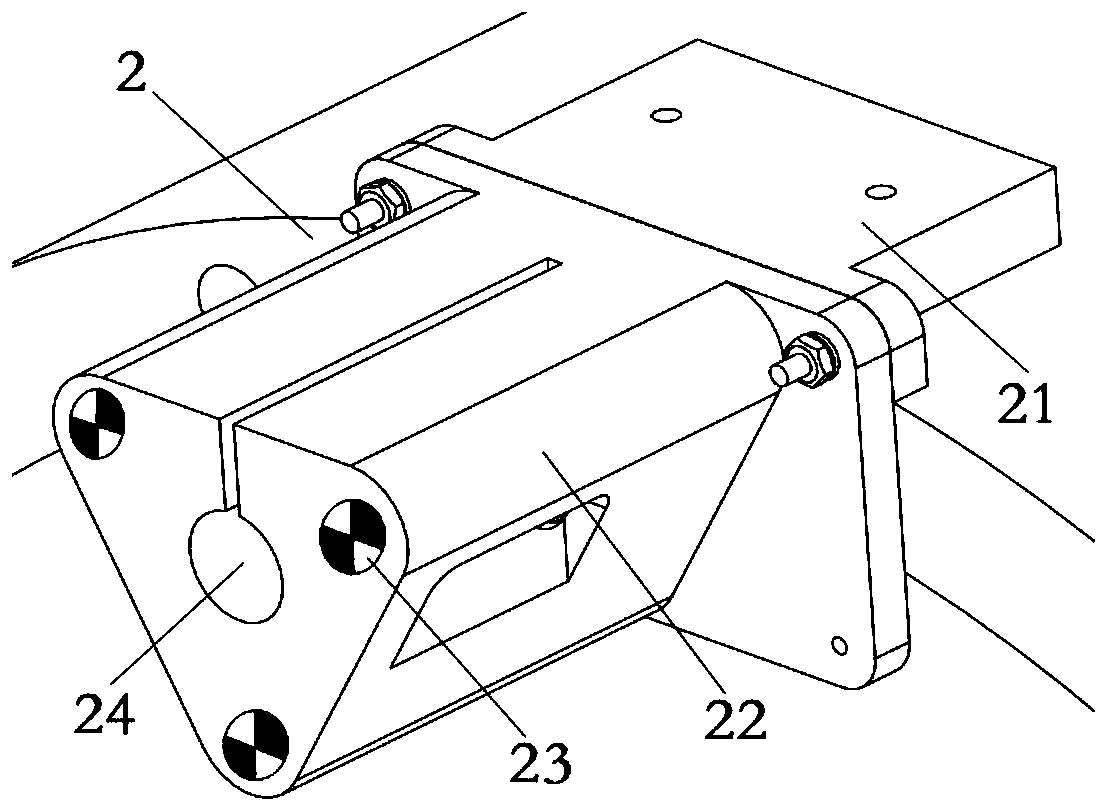

[0060] refer to figure 1 , a distributed monocular camera laser measuring device for the assembly angle of cylindrical parts, including the first cylindrical part A to be assembled and the second cylindrical part B to be assembled that are collinear in axis, equal in diameter and opposite to the assembly surface The laser device 1, the laser device support 2 and the computer 3 of relative rotation angle measurement, and the first monocular industrial camera 4 and the second monocular industrial camera 5 connected with the computer 3, wherein:

[0061] The diameter of the first cylindrical part A to be assembled and the second cylindrical part B to be assembled is 340 mm, the wall thickness of the cylinder is 15 mm, and the axes of the first cylindrical part A and the second cylindrical part B to be assembled are The X-axis of the three-dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com