Electric unidirectional stress loading device

A unidirectional stress and loading device technology, applied in the direction of measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., can solve the problems that the loading speed and loading force cannot be accurately measured, and the loading quality cannot be guaranteed. Achieve the effect of simple structure, avoiding occupying space and compact volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

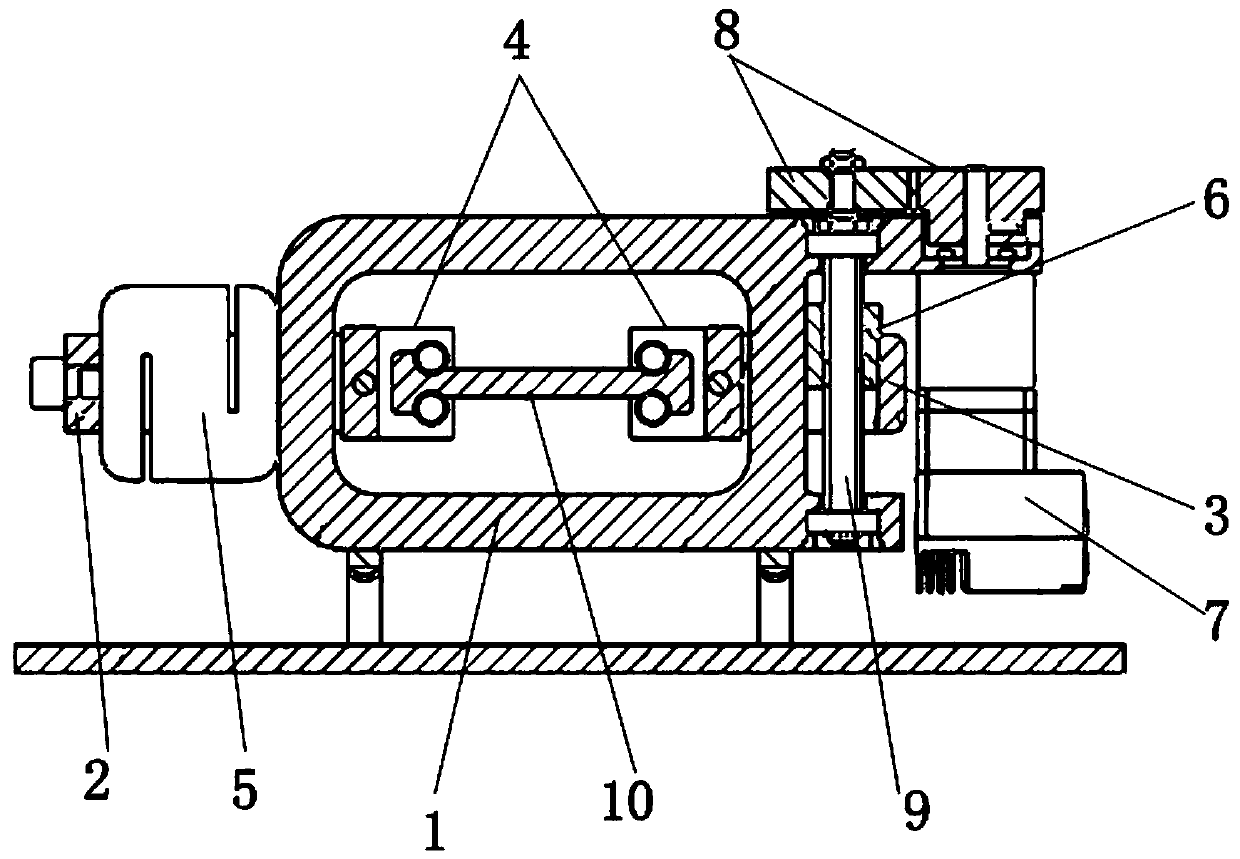

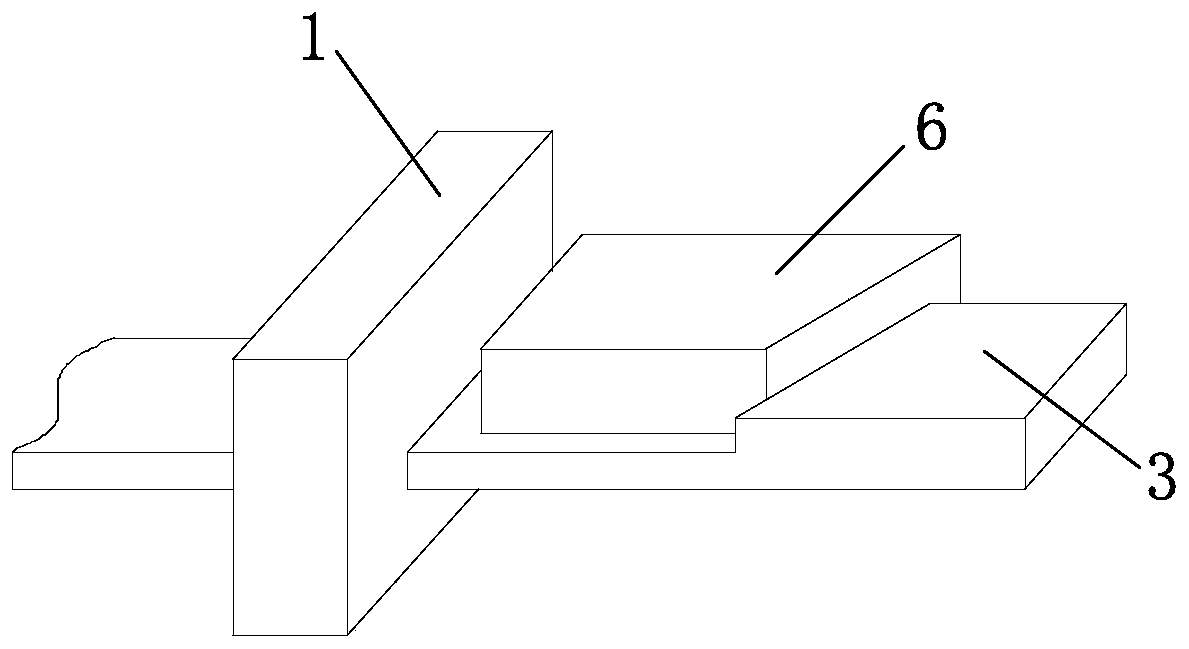

[0032] Such as figure 1 , 2 As shown, an electric one-way stress loading device disclosed in the present invention includes a bearing frame 1 with a rectangular frame structure, and coaxial chutes are arranged on the vertical sides of the bearing frame 1, and are positioned through the chute respectively. The force-measuring slider 2 on the left side of the load frame 1 and the inclined-plane loading slider 3 on the right side of the load-bearing frame 1 are respectively connected to the force-measuring slider 2 and the inclined-plane loading slider 3 and located inside the load frame 1 The sample holder 4, the pressure sensor 5 arranged in the cavity outside the force-measuring slider 2 and the bearing frame 1, and the inclined-plane screw nut 6 arranged in the cavity outside the inclined-plane loading slider 3 and the bearing frame 1 , the deceleration stepping motor 7 installed on the right side of the bearing frame 1, a gear transmission mechanism 8 fixed on the output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com