Redundant series-parallel electro-hydraulic hybrid drive anthropomorphic mechanical leg

An electro-hydraulic hybrid, mechanical leg technology, applied in the field of anthropomorphic mechanical legs, can solve the problems of large exercise load, inflexible movement, small driving force, etc., and achieve the effect of reducing joint load, reducing energy consumption, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

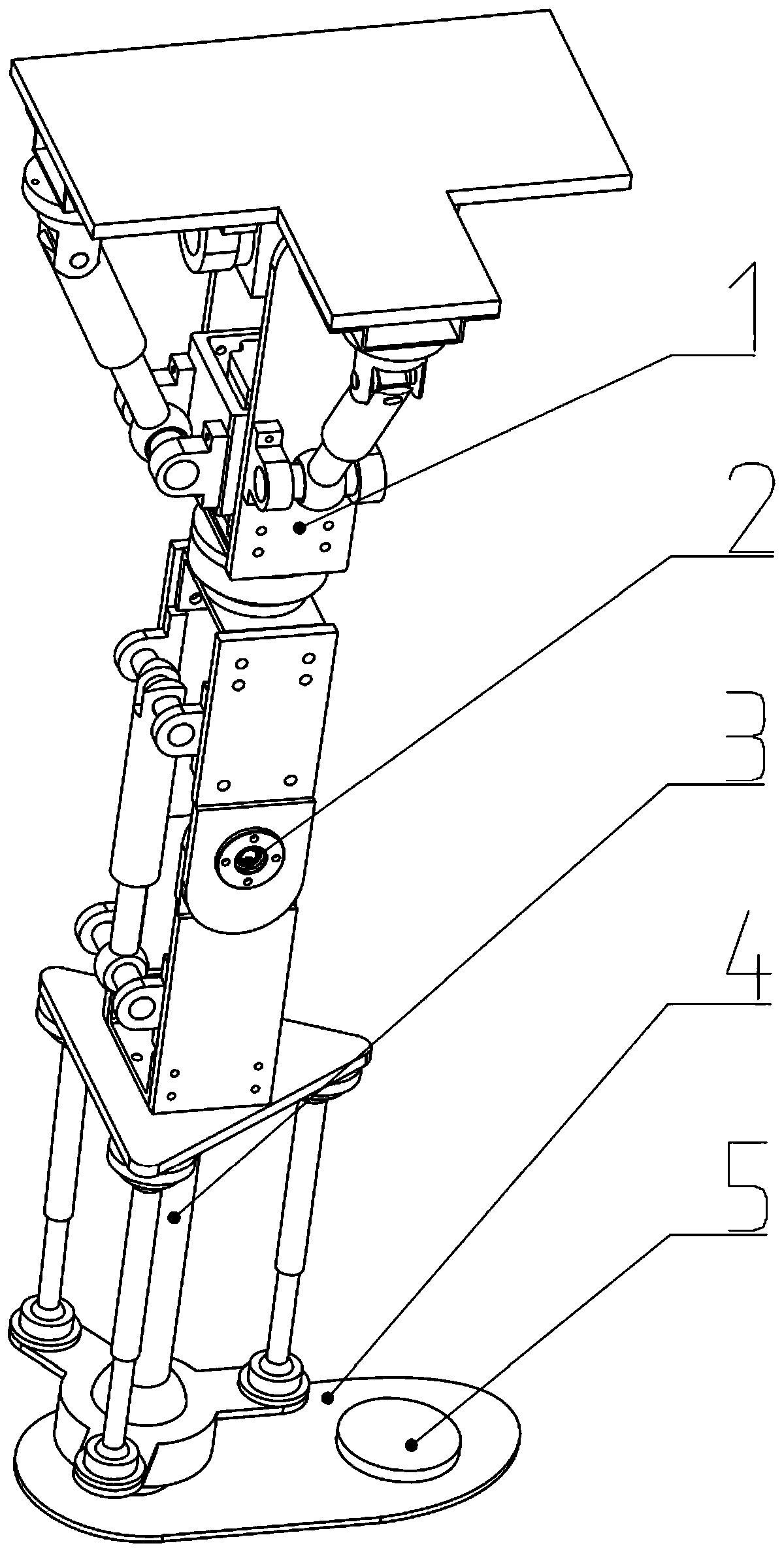

[0025] Such as Figure 1~4 As shown, a redundant hybrid electro-hydraulic hybrid drive anthropomorphic mechanical leg, including a hip joint module 1, a knee joint module 2, an ankle joint module 3, a foot 4 and a six-dimensional sensor 5; the hip joint module 1 is fixed on the robot's Physically, the knee joint module 2 is connected under the hip joint, the ankle joint is fixed on the knee joint module 2 , the sole 4 is fixed on the ankle joint, and the six-dimensional force sensor 406 is fixed on the sole 4 .

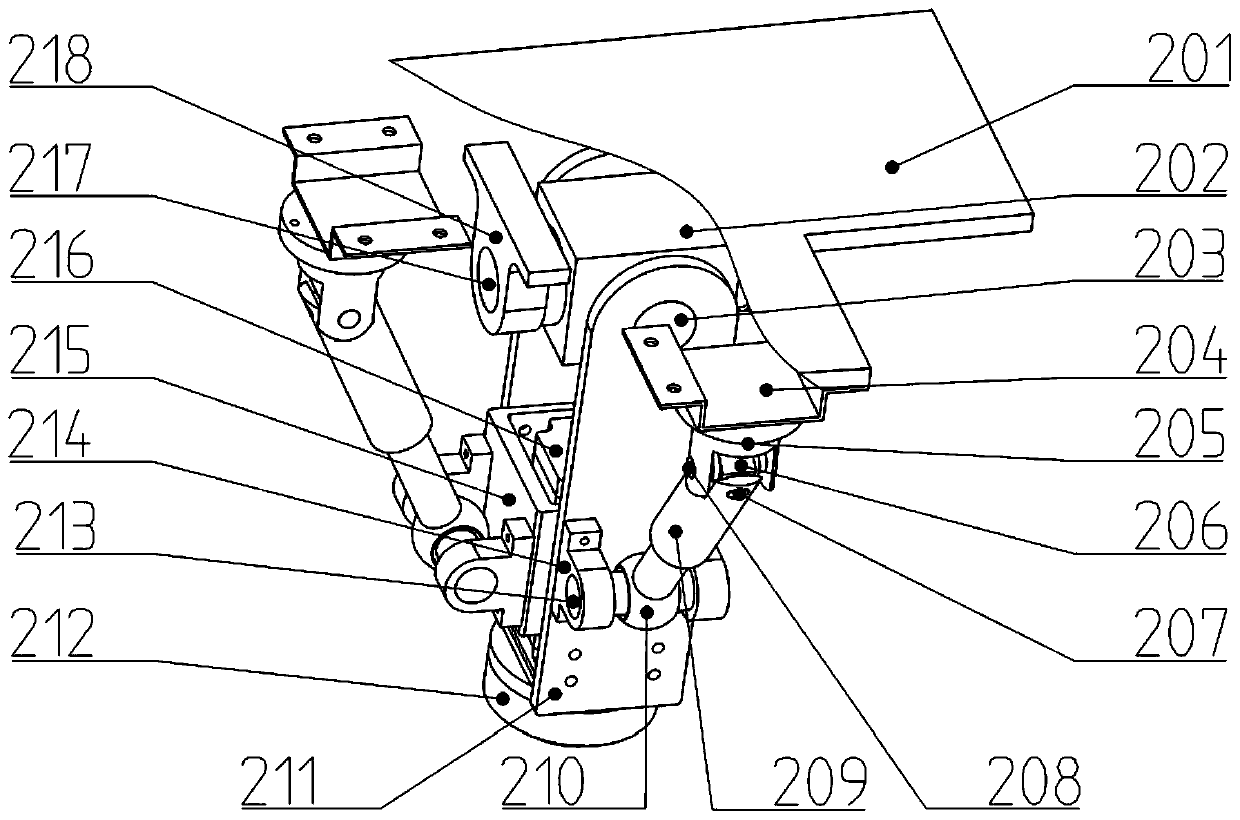

[0026]The hip joint module 1 includes a hip joint fixed platform 201, a hip joint direction changing branch chain, a first middle block 202, a first main shaft 203, a first thigh rod 211, a harmonic reducer 212, a side connecting plate 215, a first Motor 216, first side shaft 217 and side shaft support 218; two side shaft supports 218 are all fixed on the hip jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com