Robot grinding device and grinding method based on six-dimensional force sensor and binocular vision

A technology of six-dimensional force sensor and binocular vision, which is applied in the direction of grinding machine tool components, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problem of six-dimensional force sensor measuring structural damage, six-dimensional force sensor Damage, incomplete grinding information, etc., to achieve good grinding efficiency, good grinding effect, and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

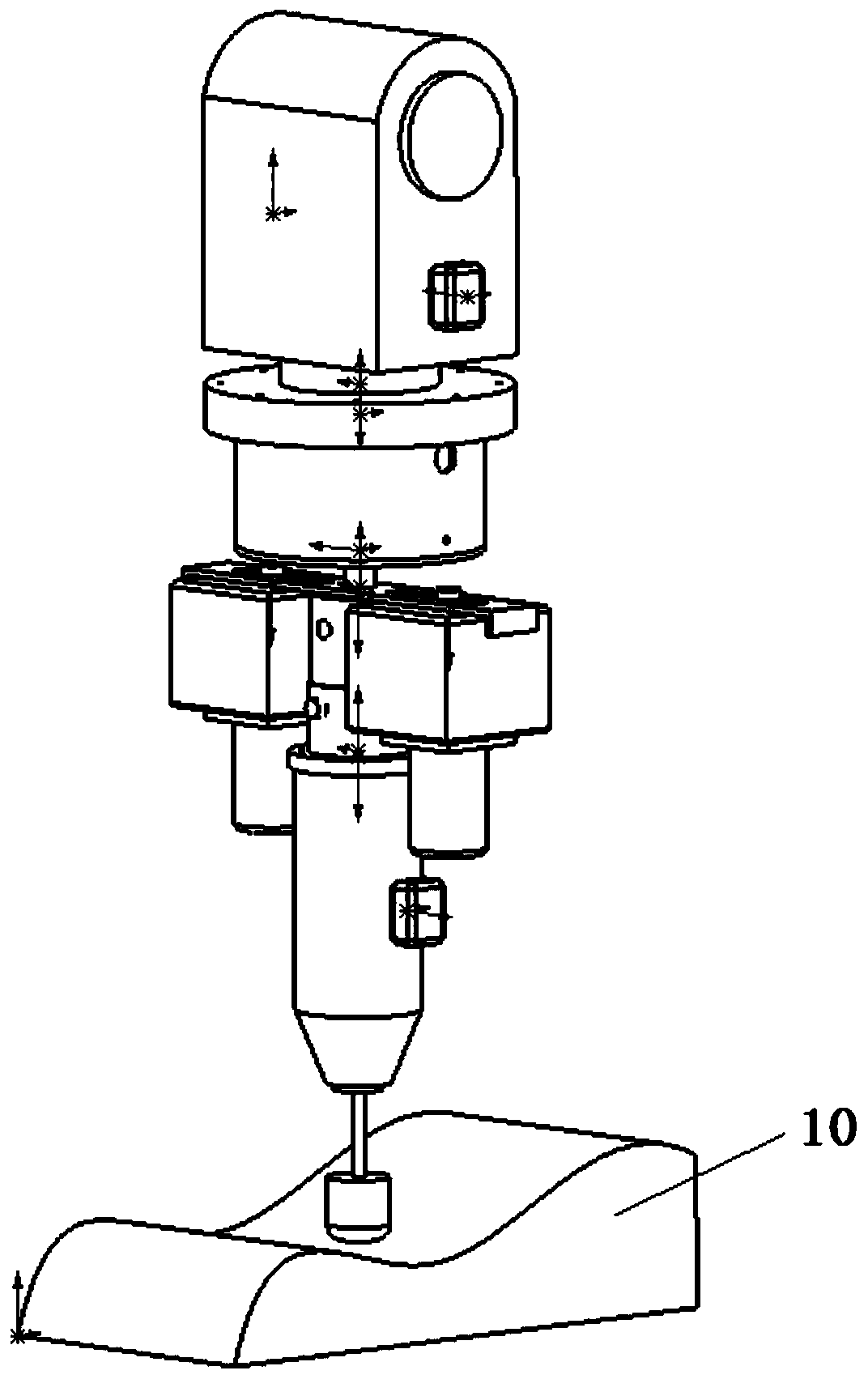

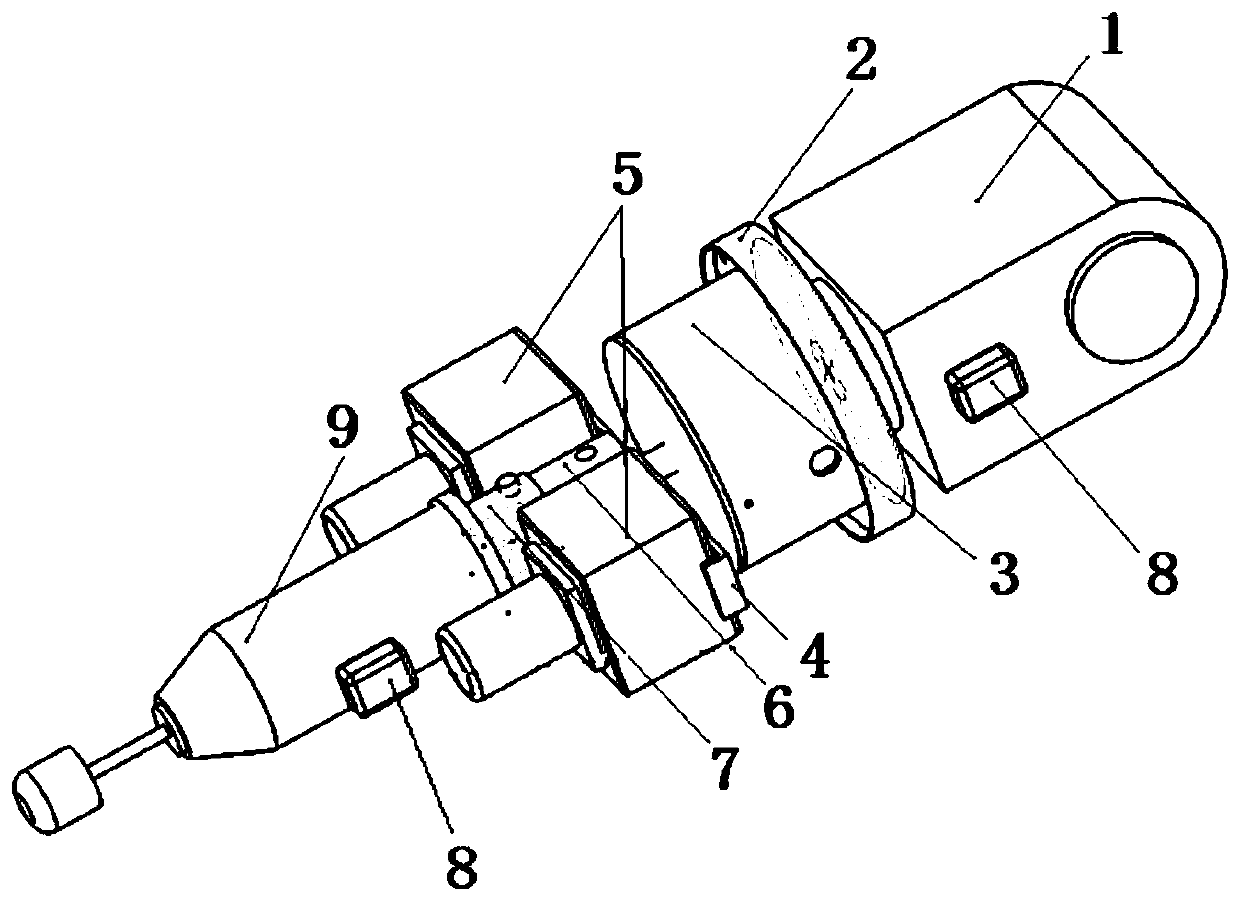

[0053] Such as figure 1 and figure 2 As shown, a robot grinding device based on a six-dimensional force sensor and binocular vision, including a mechanical arm 1, a sensor holder 2, a six-dimensional force sensor 3, a camera bracket 4, an industrial camera 5, a flexible connector 6, and a motor fixing Seat 7, grinding motor 9 and biaxial acceleration sensor 8.

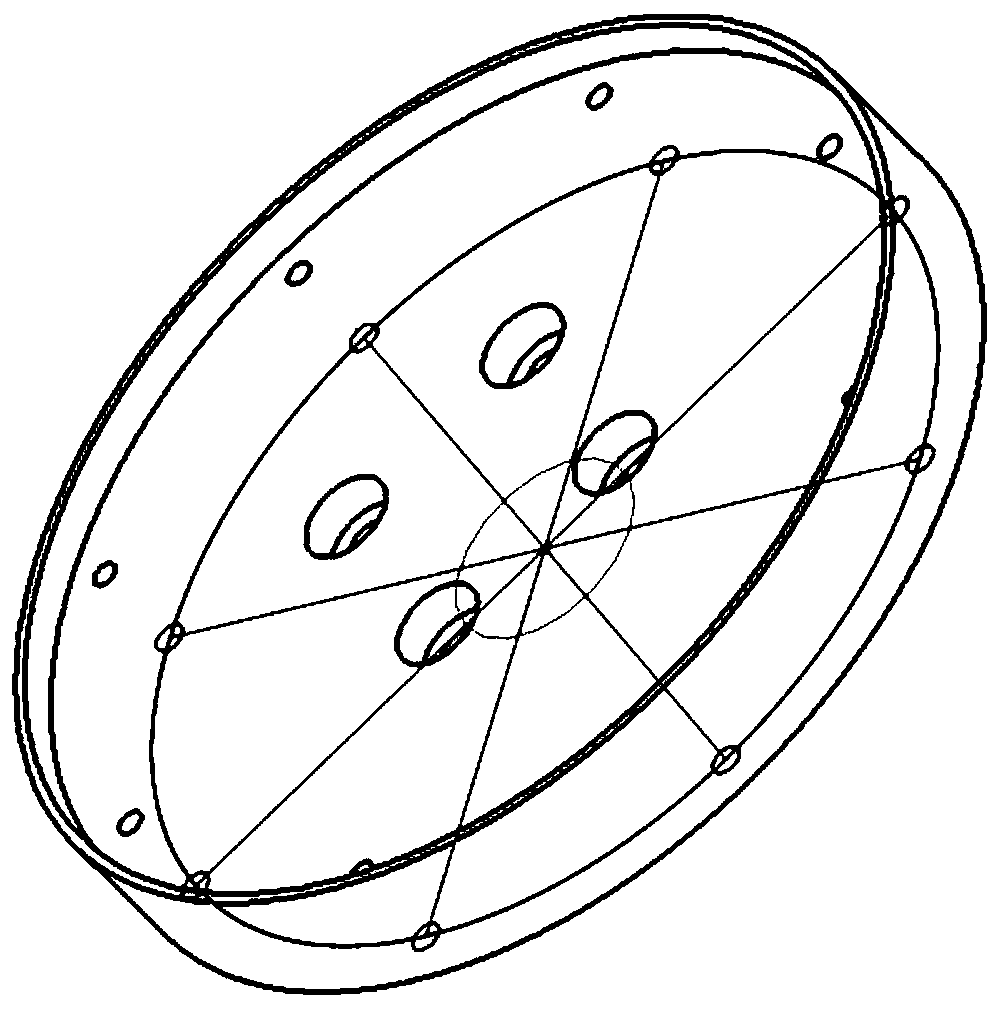

[0054] The six-dimensional force sensor is fixedly connected to the end joint of the mechanical arm through the sensor holder. The structure of the sensor holder is as follows: image 3 shown.

[0055] The six-dimensional force sensor is flexibly connected to the motor holder through a flexible connector. The flexible connector is preferably a cylinder made of rubber material, and the cylinder preferably has a diameter of 30 mm and a height of 50 mm. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com