Center-outboard wing fuel delivery system pipeline airtight test device and method

A technology of airtight test and oil system, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, which can solve the problems of limited operating space and inconvenient operation of the system

Inactive Publication Date: 2019-08-20

SHAANXI AIRCRAFT CORPORATION

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the operating space of the system is limited and inconvenient to operate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

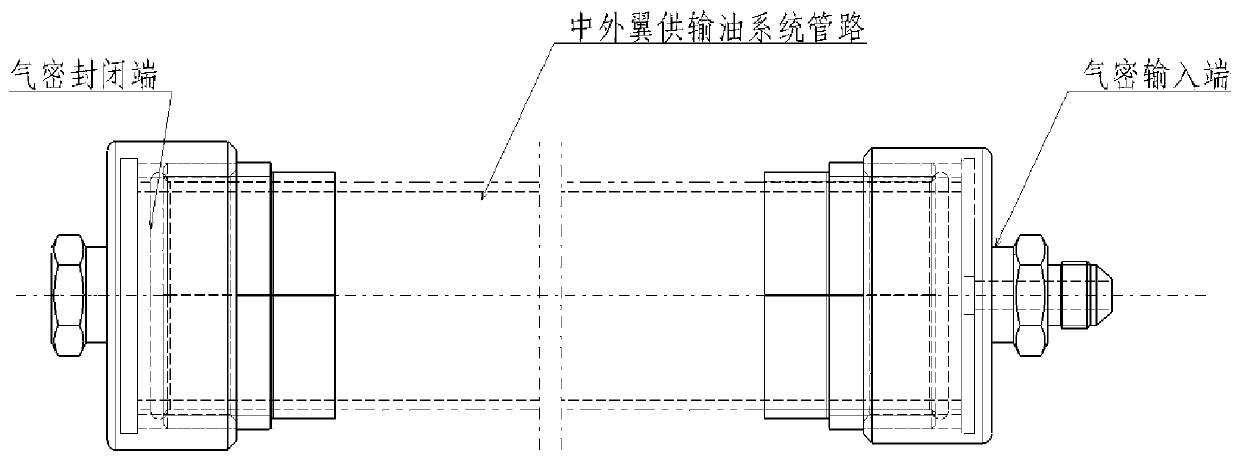

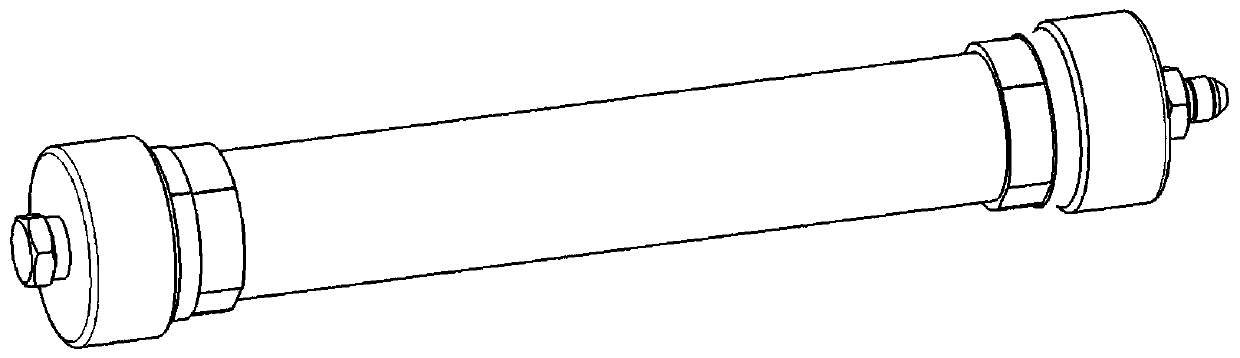

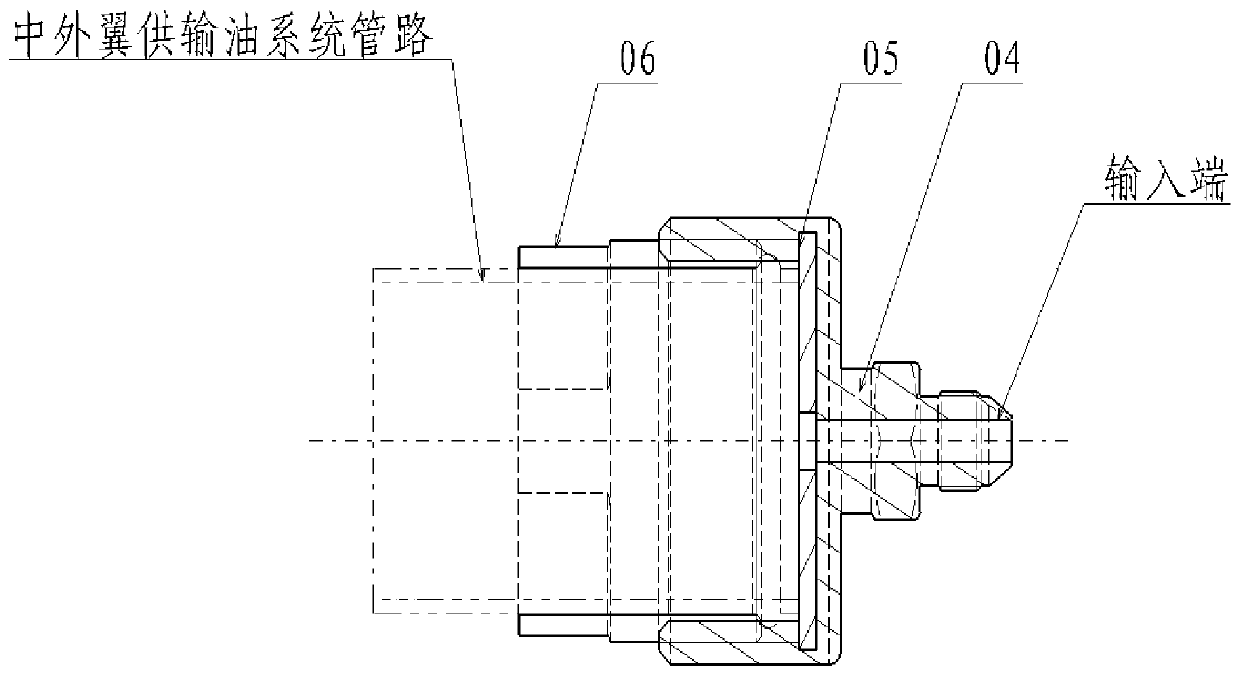

[0035] The invention discloses a method and a device for the airtightness test of the pipeline of the oil supply system of the middle and outer wings. Taking a certain type of transport plane as the platform, it consists of six parts: threaded cap 01, sealing rubber gasket 02, separate screw sleeve 03, threaded plug 04, sealing rubber pad 05 and separate screw sleeve 06.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of aviation manufacturing, and provides a center-outboard wing fuel delivery system pipeline airtight test device and method. The method comprises steps: two half pipe threads of a first split screw sleeve (03) and a second split screw sleeve (06) surround a flared tube of a tested product, close to a small boss, a thread plug cap (01) is connected withthe first split screw sleeve (03) and a thread plug (04) is connected with the second split screw sleeve (06); when an air source enters the input end thread plug (04) from a test bench, airtight test on the system pipeline can be carried out; and when not working, the threaded plug cap (01) and the first split screw sleeve (03) are separated and the thread plug (04) and the second split screw sleeve (06) are separated.

Description

technical field [0001] The invention belongs to the technical field of aviation manufacturing, and relates to an airtight test method and device for fuel system pipelines. Background technique [0002] The oil supply system for the middle and outer wings belongs to the aircraft fuel system, and the tightness of the connection between the pipeline parts is very important. For pipelines designed with threaded or flanged connections, it is better to implement the airtight test of the pipelines by installing gaskets and blocking plates and connecting them with flanges or using threaded plugs. But for the flaring pipe, because the wall thickness of the pipe is thin and the flaring boss is small, it is difficult to locate, so the airtight test is relatively difficult to achieve. For flared pipes, in the past, rubber hoses were mostly used on the outer casing of the pipes, and the outer surface was fixed with clamps. The degree of bonding between the rubber hose and the pipes is n...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M3/02

CPCG01M3/02

Inventor 陈卫红韩金辰李峰苏智韩波王波胡朝阳陈权仁李亚兰王大群

Owner SHAANXI AIRCRAFT CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com