Lens main section calibration device

A technology of calibration device and main section, applied in the direction of testing optical performance, etc., can solve the problems of repeated calibration, poor main section accuracy, inconvenient prism, etc., and achieve the effect of improving work accuracy and reliability, avoiding errors, and avoiding delay errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

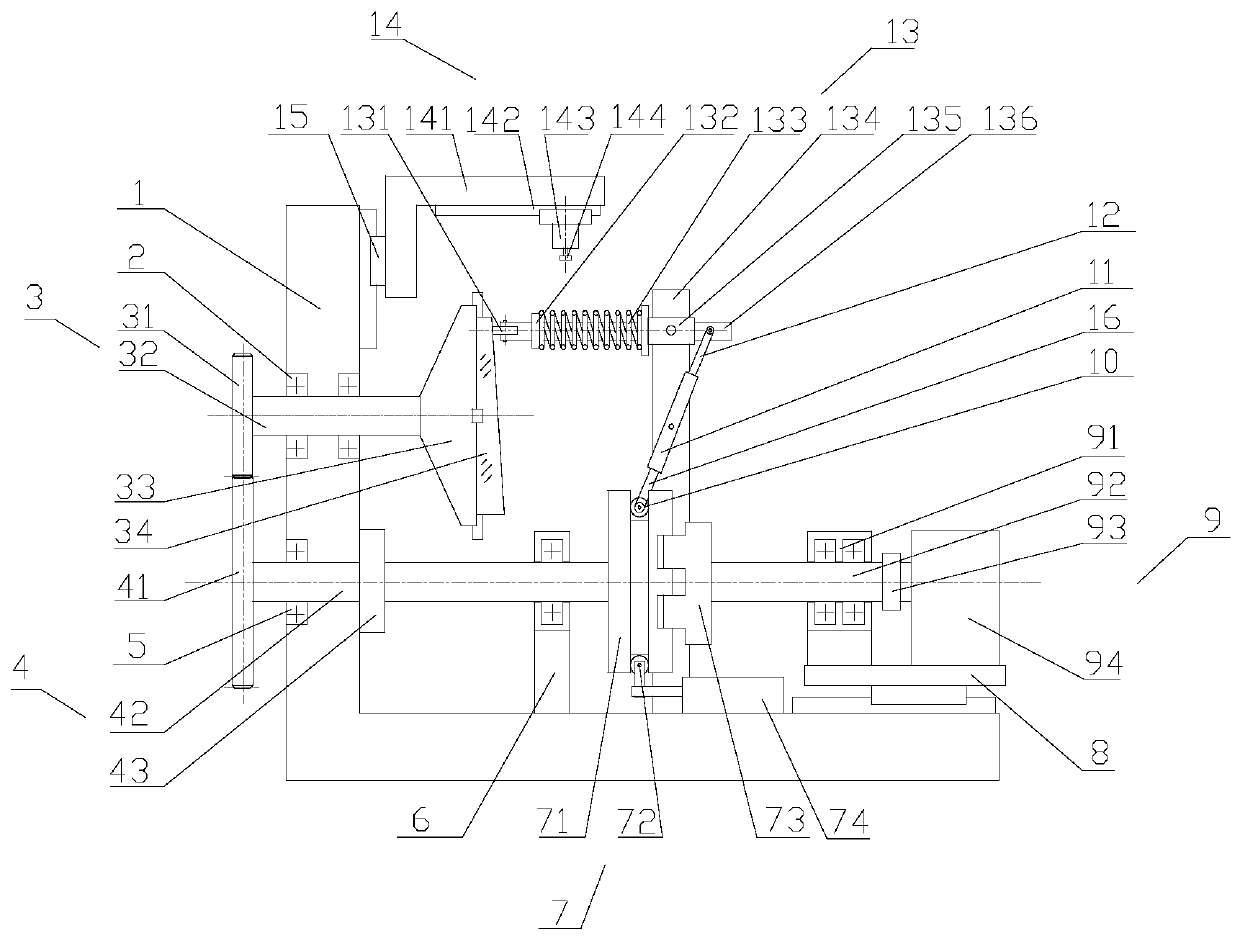

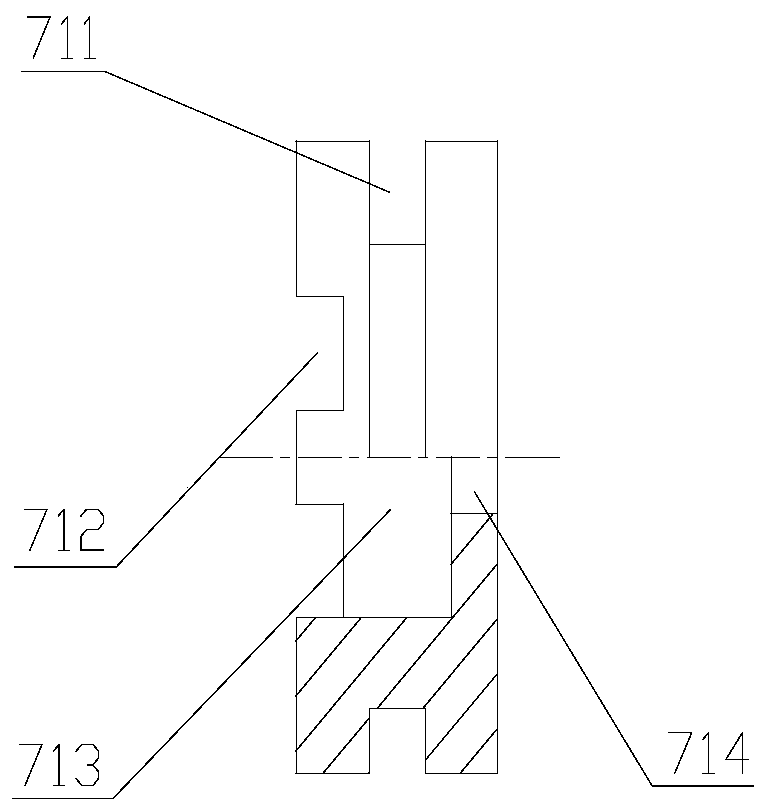

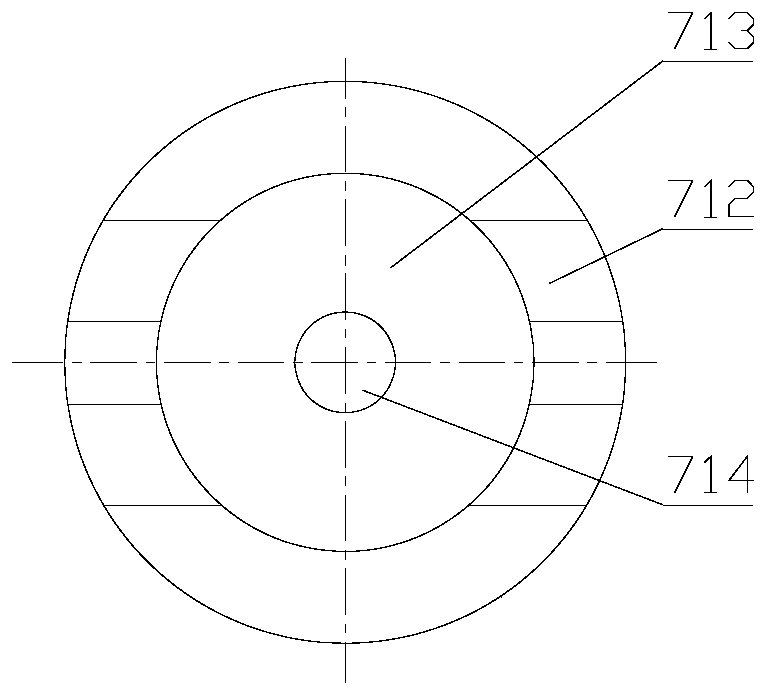

[0044] A lens main section calibration device, including a base 1 and a rotating mirror assembly 3 installed on the base 1, a transmission assembly 4, a clutch assembly 7, a power source assembly 9, a measurement assembly 13 and a marking assembly 14; figure 1 shown. The base 1 is an L-shaped base, including a side surface and a bottom surface. The mirror body 34 to be tested is installed on the rotating mirror assembly 3; the power source assembly 9 drives the rotating mirror assembly 3 to rotate through the clutch assembly 7 and the transmission assembly 4.

[0045] Measuring assembly 13 comprises pressure roller 131, nut 132, spring 133, column 134, slide seat 135 and guide rod 136; Column 134 is vertically fixed on the bottom surface of base 1, and slide seat 135 is flexibly connected to the top of column 134, guide The rod 136 runs through the sliding seat 135 and is slidingly connected with the sliding seat 135; one end of the guide rod 136 is rotationally connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com