Steel pipe scaffold fastener mechanical property testing machine

A testing machine and scaffolding technology, used in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve problems such as fragmentation and poor operator protection, and achieve extended service life, reduced impact, and reduced impact. The effect of small kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

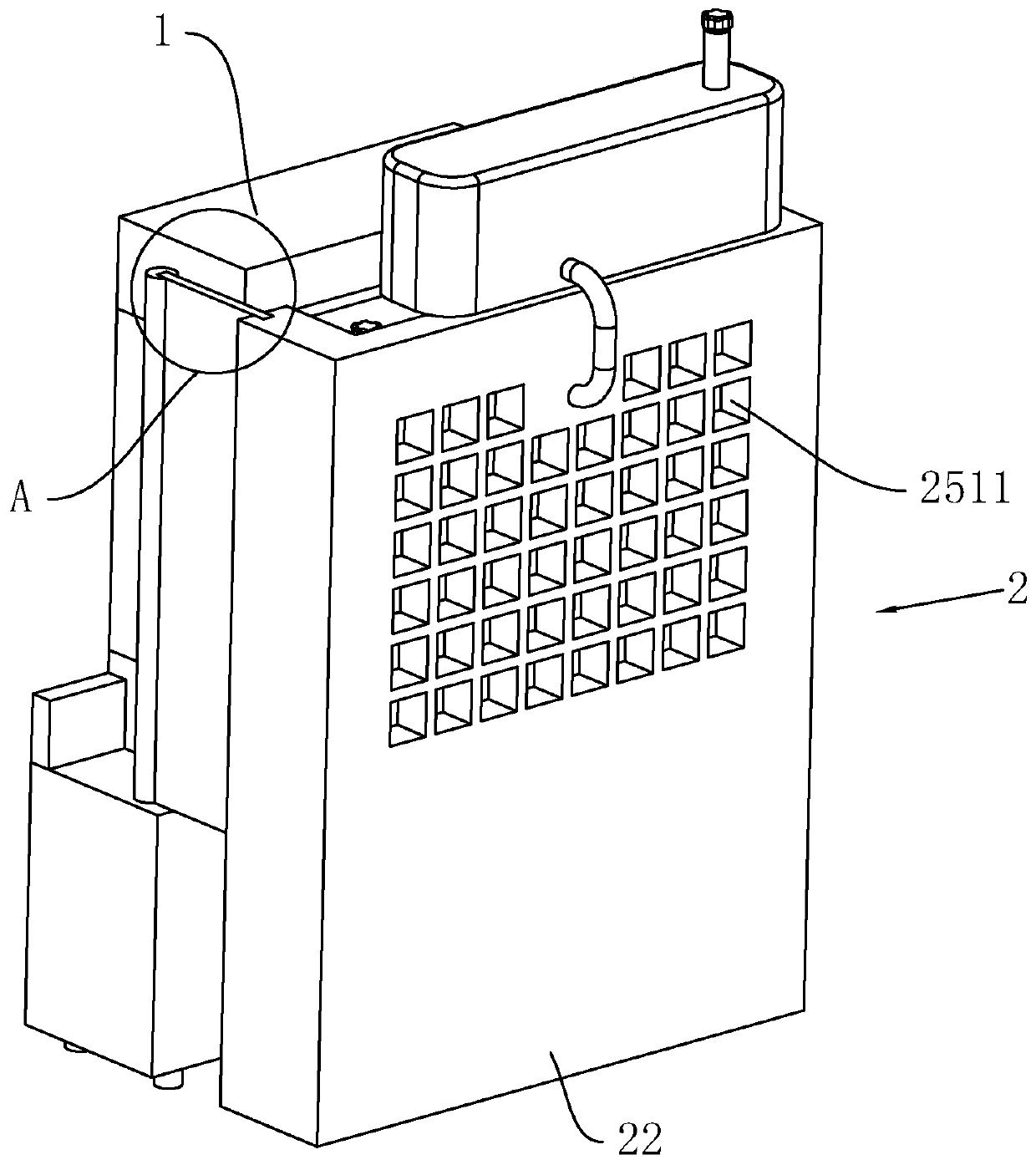

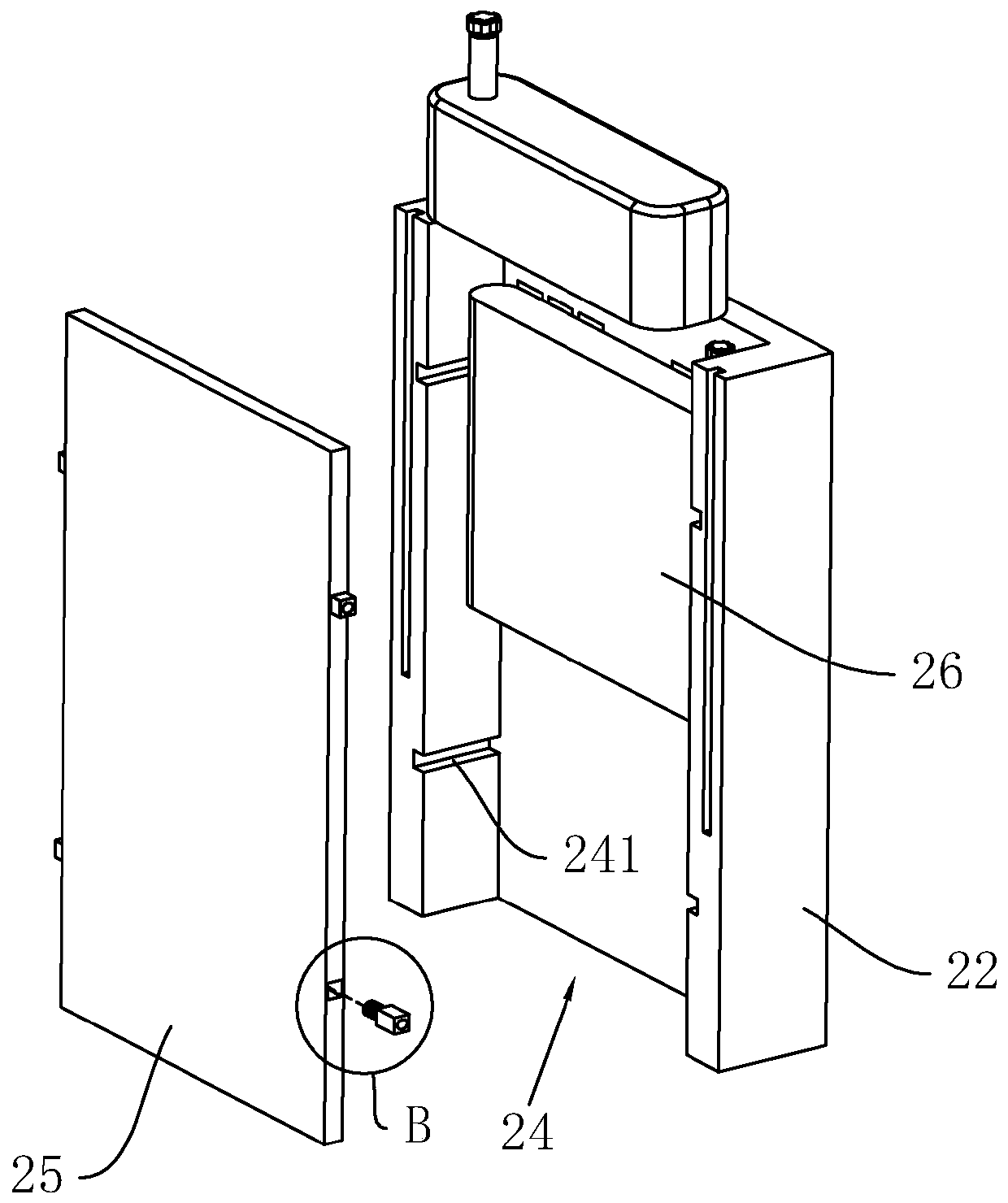

[0038] refer to figure 1 and figure 2 , is a steel pipe scaffold fastener mechanical performance testing machine disclosed in the present invention, comprising a testing machine body 1 and a protective structure 2 installed on the testing machine body 1 .

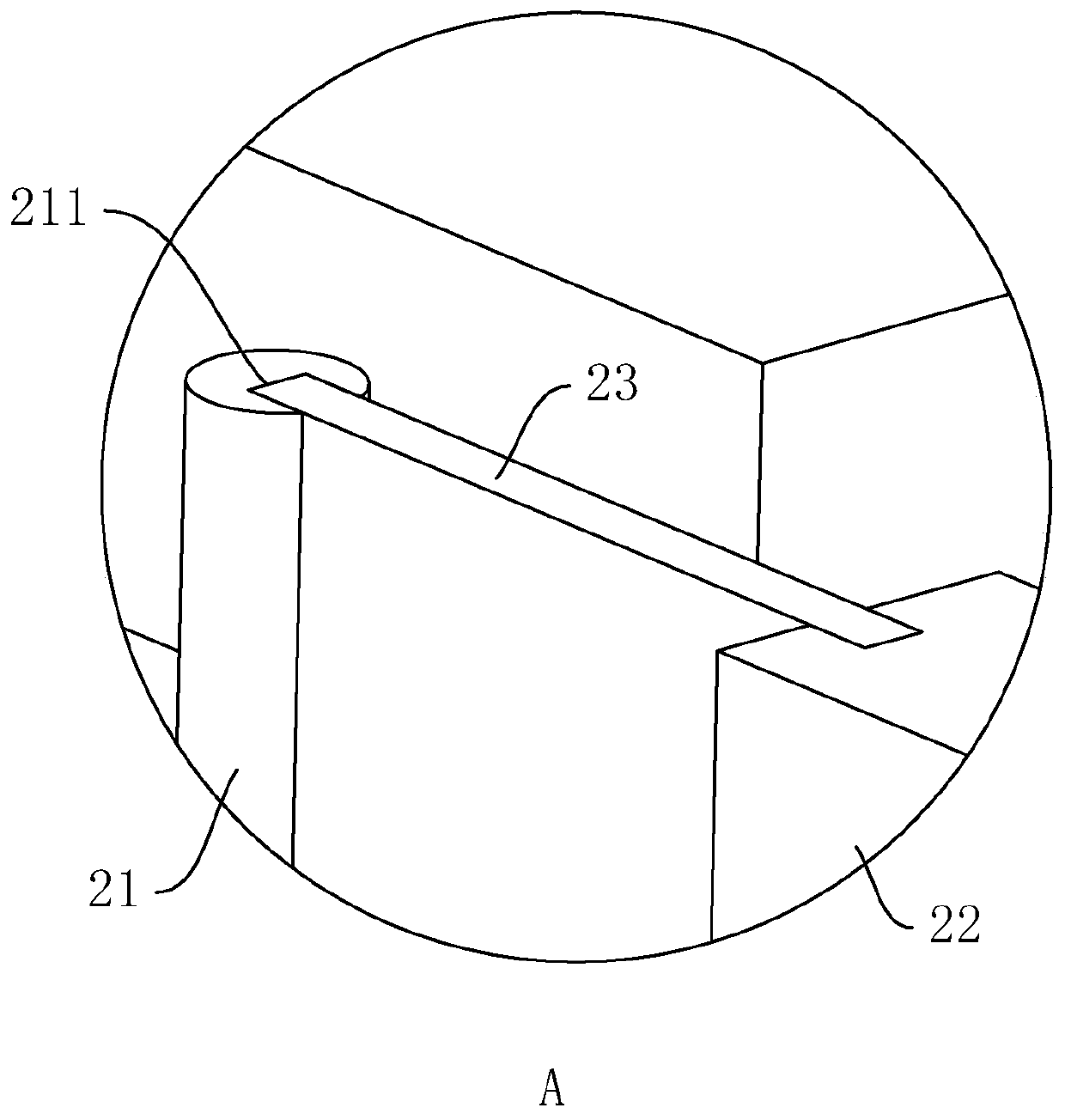

[0039]The protective structure 2 includes a support column 21 welded on the testing machine body 1 and a protective plate 22 connected to the support column 21 , the protective plate 22 and the support column 21 are connected by a rubber sheet 23 . Both the support column 21 and the protective plate 22 are provided with installation grooves 211, and the rubber sheet 23 is installed in the installation grooves 211 and fixedly connected by glue. The rubber sheet 23 covers the gap between the support column 21 and the protective plate 22, preventing the broken pieces of the steel pipe scaffold fastener fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com