Simulation model verification, establishment method and application in thin-walled copper pipe welding production process

A technology of simulation model and production process, applied in design optimization/simulation, CAD numerical modeling, instruments, etc., can solve the problem that the temperature field change at the welding seam of thin-walled copper pipe cannot be obtained, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the technical solutions of the present invention, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

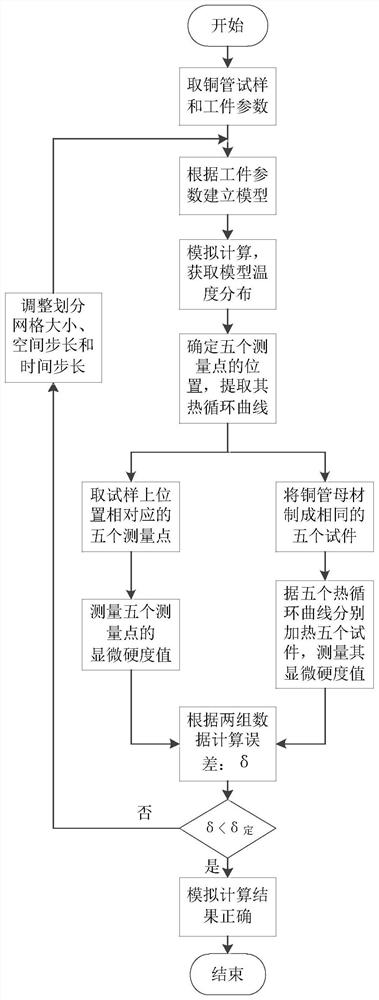

[0041] In an embodiment of the present invention, a method for verifying a simulation model in a thin-walled copper pipe welding production process includes the following steps:

[0042] Step 1, parameter acquisition

[0043] Obtain the base material for the production of thin-walled copper tubes, the thin-walled copper tube samples produced by welding with the base metal, and the process parameters in the welding production process; and measure the microhardness P1 of the thin-walled copper tube samples;

[0044] Step 2, simulation model establishment

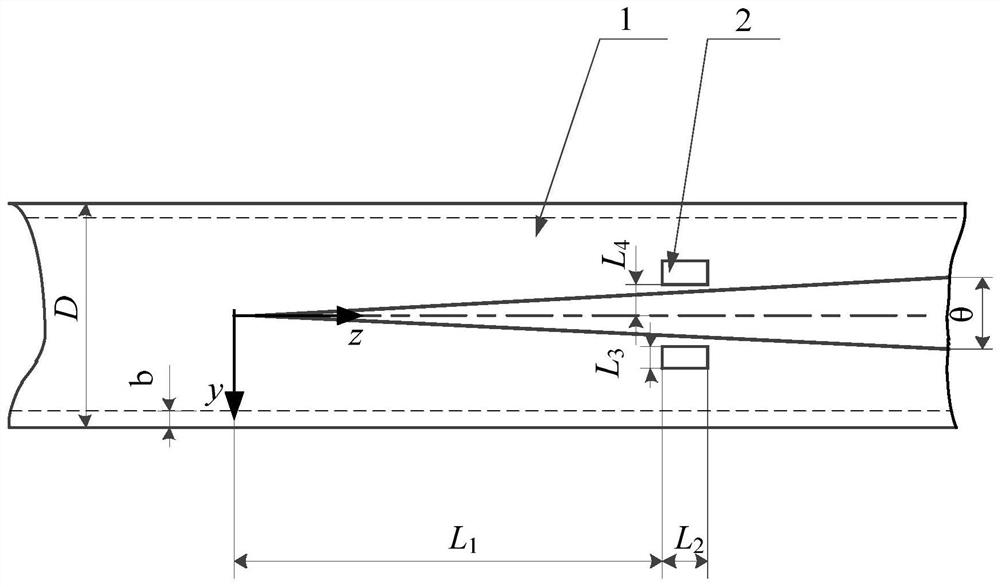

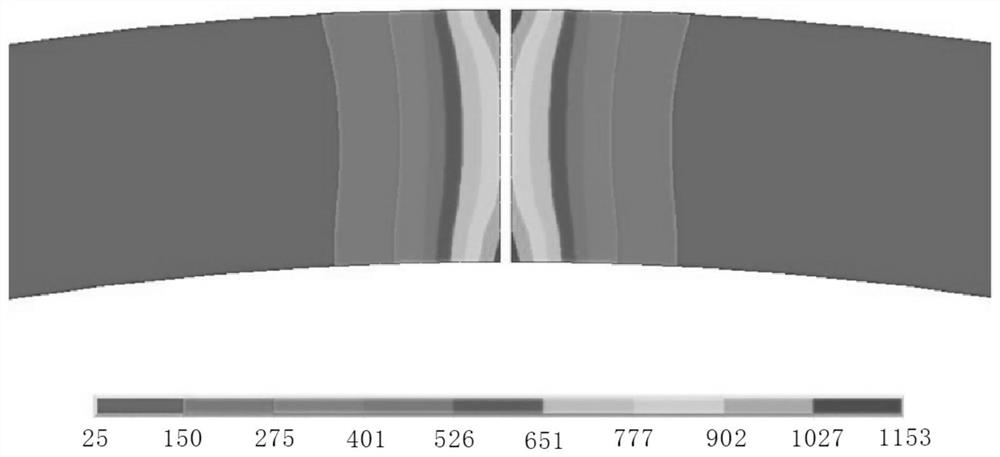

[0045]According to the process parameters obtained in step 1, use DEFORM to establish a simulation model of the thin-walled copper pipe welding production process; and determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com