Flexible online measuring device for part diameter

A measuring device and aperture technology, which is applied in the field of flexible online measuring device for part aperture, can solve problems such as inability to optimize production parameters in real time, guide production practice, fail to meet continuous processing of large-scale assembly lines, and fail to process and analyze measurement data in real time, etc. Achieve the effect of reducing human measurement error factors, reducing indirect measurement and system complexity errors, and solving high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

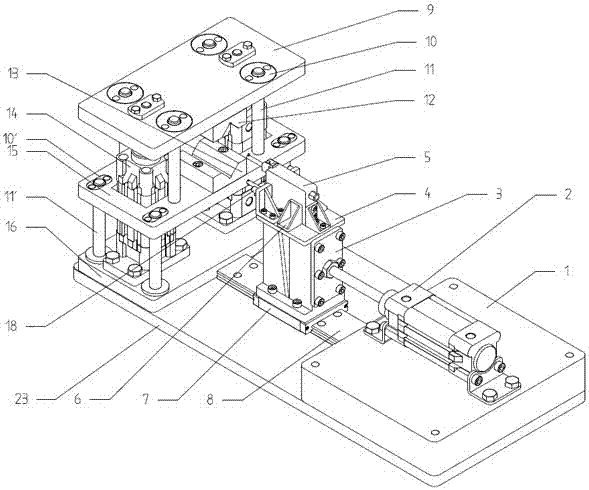

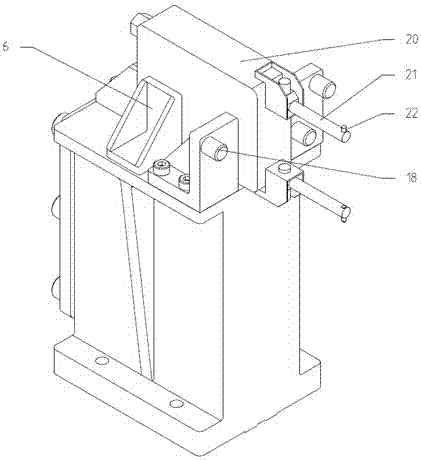

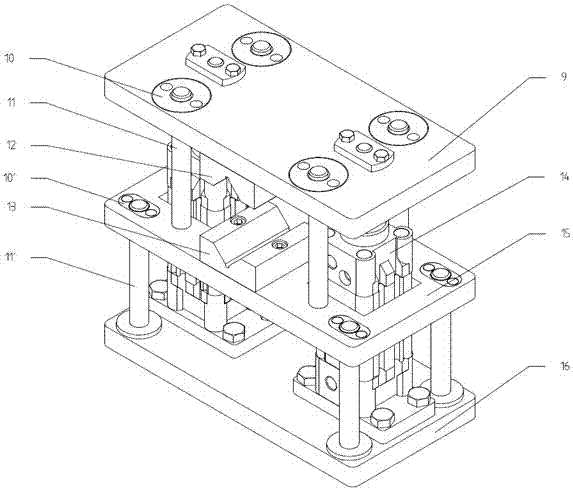

[0024] Such as figure 1 , figure 2 As shown, a flexible on-line measurement device for part aperture of the present invention is equipped with a lift-type adjustable positioning platform on one side of the workbench 23; 7 and the guide rail 8 form a sliding pair, and the base 4 is moved left and right on the guide rail 8 through the push rod movement of the drive cylinder 2. The measurement component 5 is installed on the top of the base 4, and the platform of the base 4 and the measurement component 5 are fixed by the corner seat 6 Connection, the top of the base 4 on both sides of the measuring assembly 5 is equipped with cylindrical pins 18, and the connecting plate 3 is installed on one side of the base 4; the base 1 is installed on the other side of the workbench 23, and the driving cylinder 2 is installed on the base 1, the cylinder ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com