Portable rapid large area thin film photosinterer

A light sintering, area technology, applied in the field of light sintering systems, to achieve the effect of low capital expenditure, low cost, and optimized production parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Overview

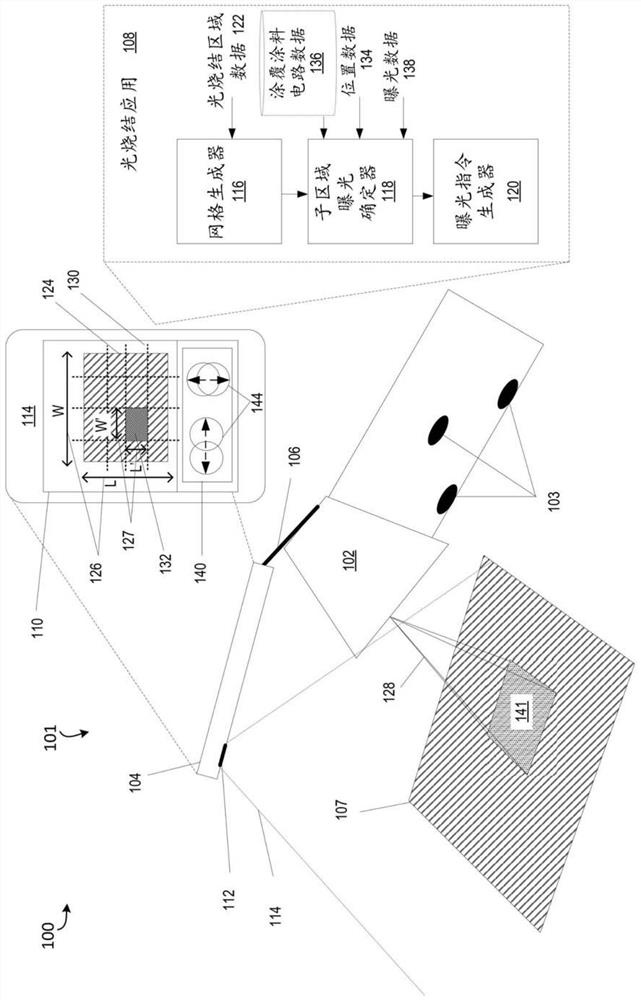

[0021] Described below are systems, devices, and methods for sintering one or more coating layers to produce solar coating circuits. A photo-sintering system may include a hand-held photo-sintering device that may be used to sinter a region including one or more coated paint layers. Operation of the photo-sintering device may be controlled using a user mobile device (or other suitable device) in data communication with the photo-sintering device through a communication port (eg, a serial port).

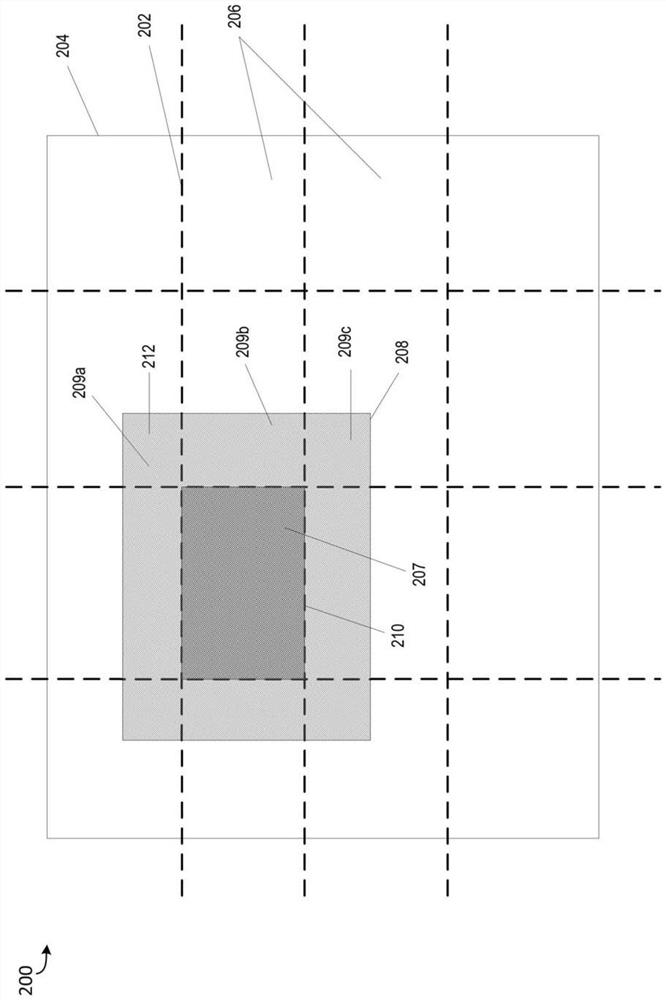

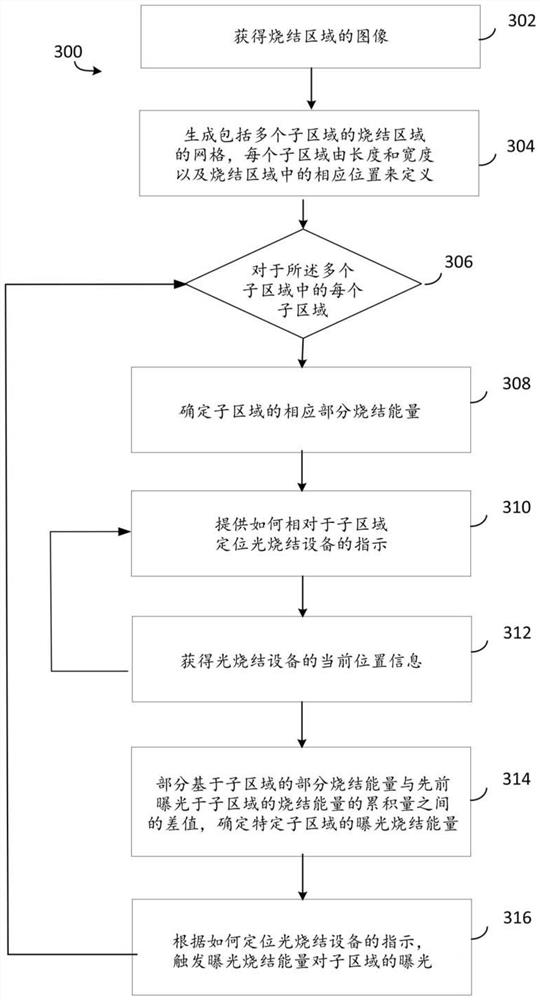

[0022] More specifically, the photo-sintering system can obtain information, such as an image of the area to be sintered (e.g., captured by a camera on the user's mobile device), through the graphical user interface (GUI) of the photo-sintering application on the user's mobile device (or tablet device). ) and the size of the area to be sintered, and generate instructions to assist the user in performing sintering, including, for example, instructions regarding the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com