Construction quality safety supervision method and system based on UWB positioning

A construction quality and safety technology, applied in image data processing, instruments, image analysis, etc., can solve the problems of poor construction quality and safety awareness, low sense of identity, and large investment of manpower and material resources, so as to improve supervision efficiency and convenience Subsequent processing and the effect of simplifying the reporting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

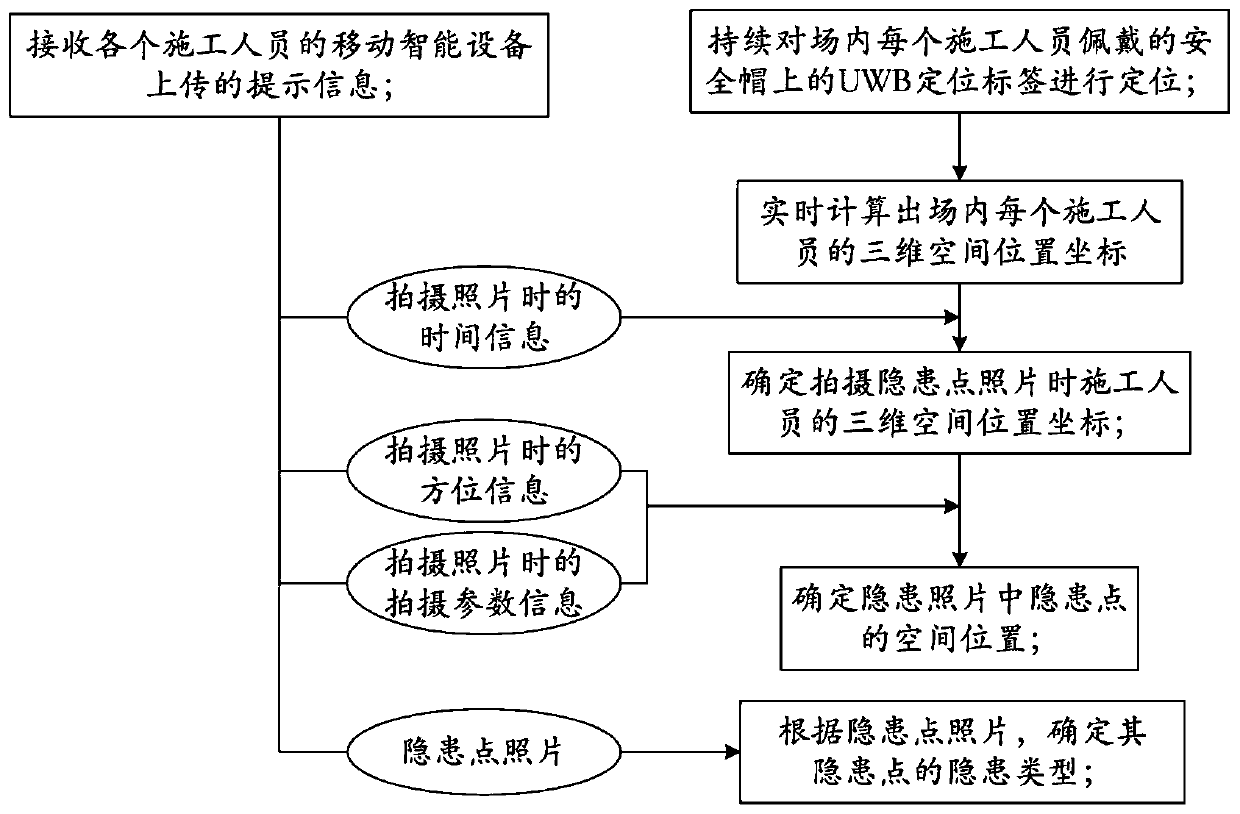

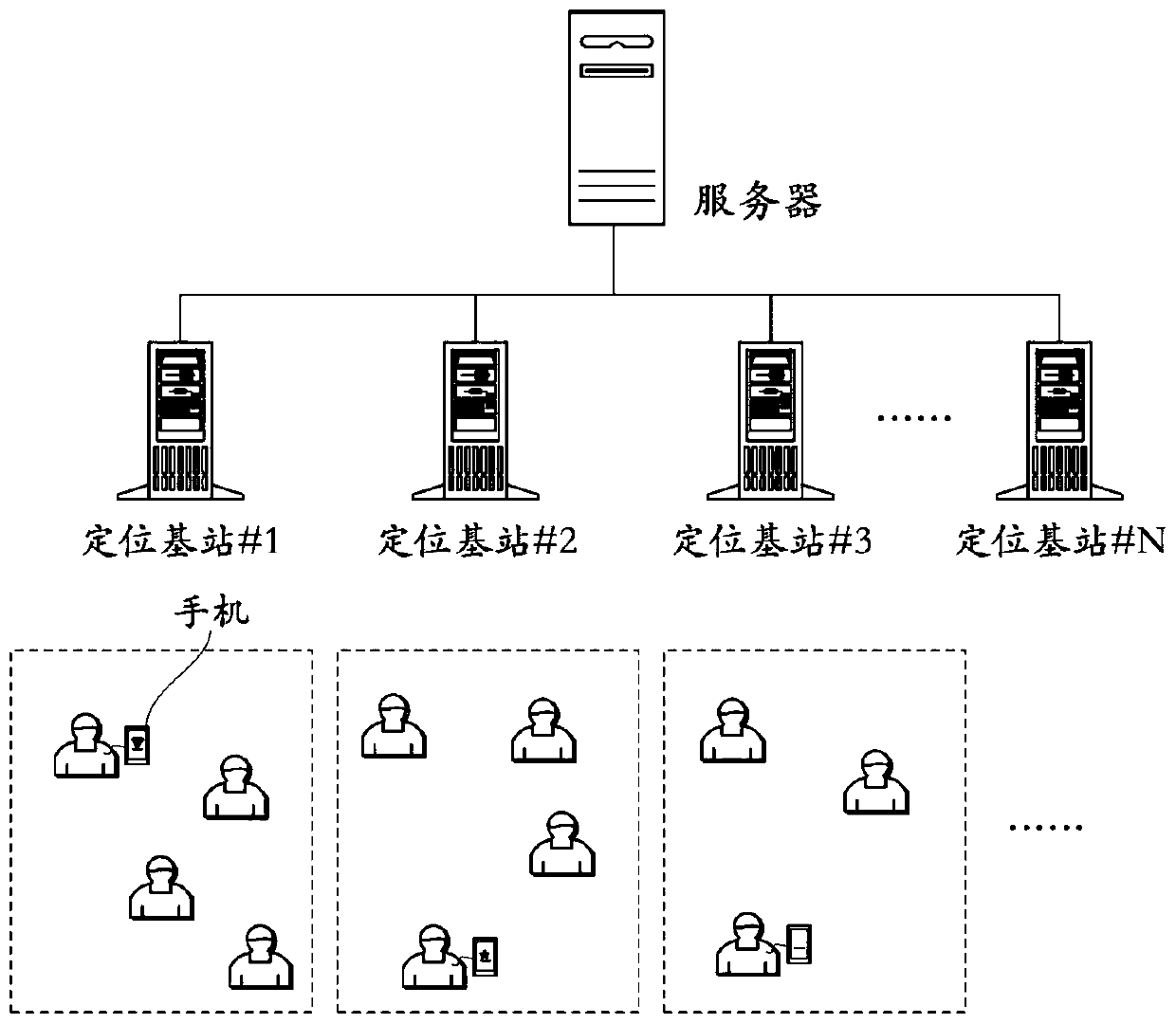

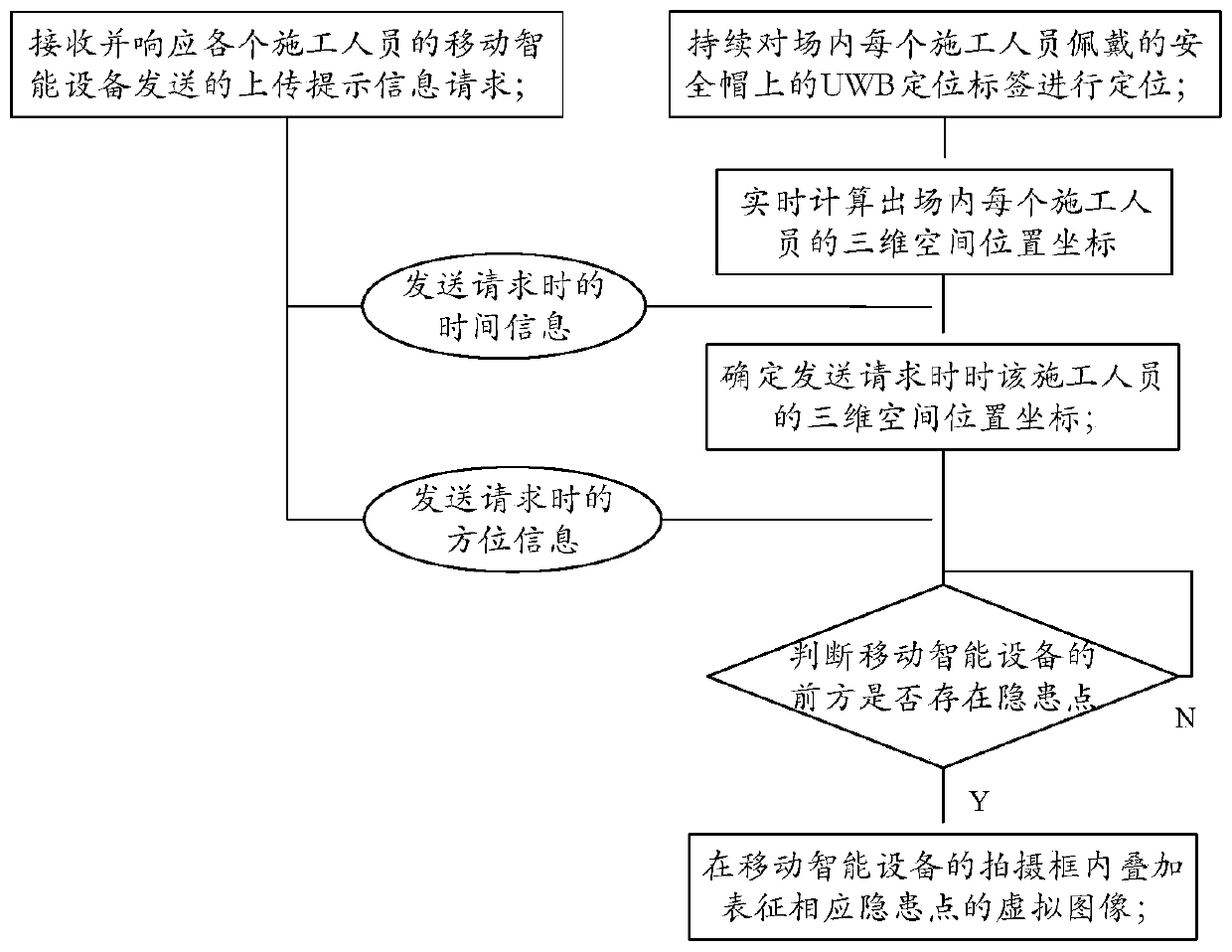

[0025] Such as figure 1 and 2 As shown, the present invention is based on UWB positioning construction quality and safety supervision method and system, the method is specifically:

[0026] On the one hand, the mobile smart devices (such as smart phones or tablet computers) of each construction worker can perform data interaction with the server, and the server receives the prompt information uploaded by the mobile smart devices of each construction worker. Wherein, the prompt information includes: the photo of the hidden danger point taken by the mobile smart device of the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com