Machining method of high aroma tea

A processing method and high-fragrance tea technology, applied in the field of high-fragrance tea processing, can solve the problems of inability to retain the floral or fruity aroma of camellia, low floral or fruity aroma, low sweetness of tea leaves, and the like, achieving no bitterness, Improve sweetness and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

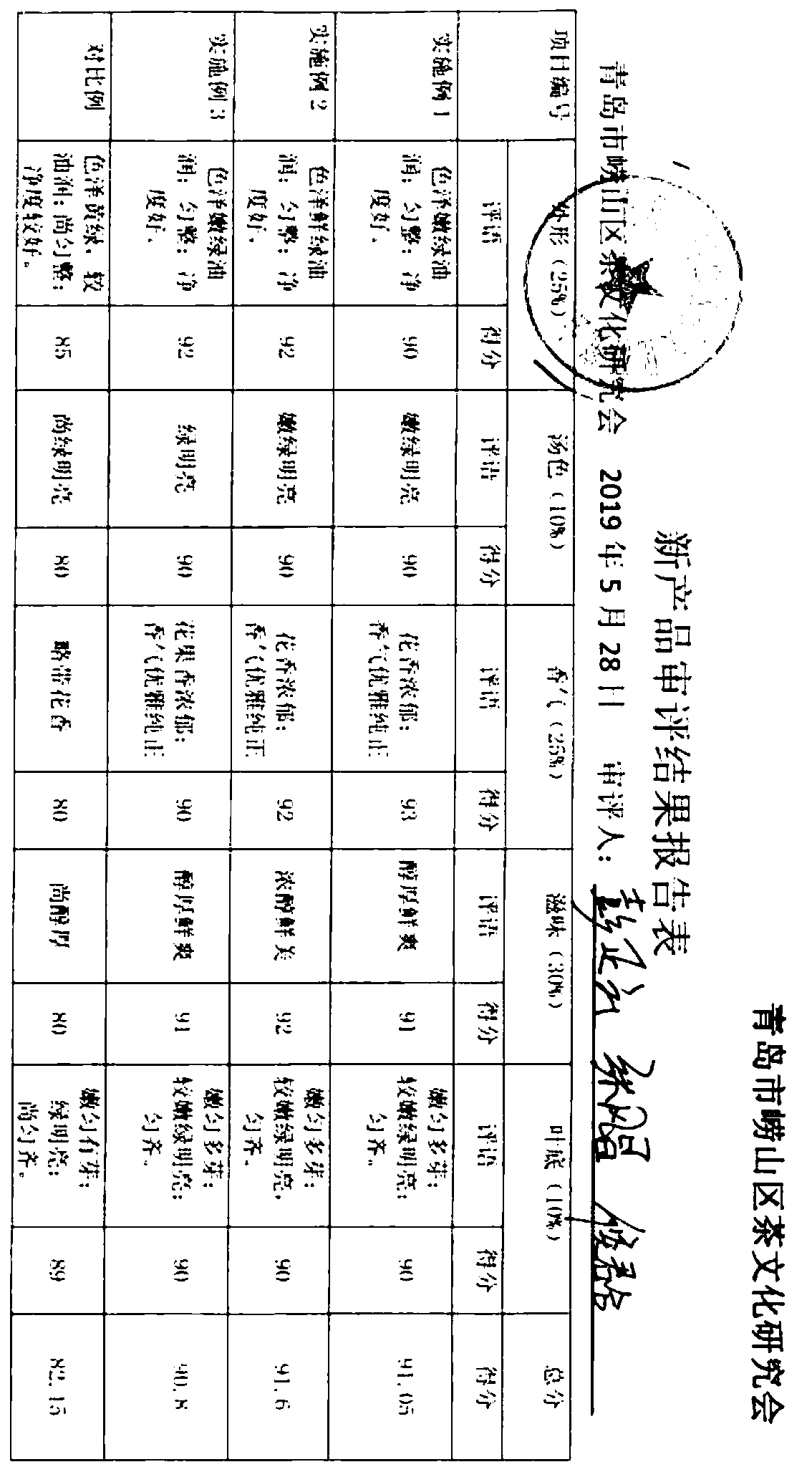

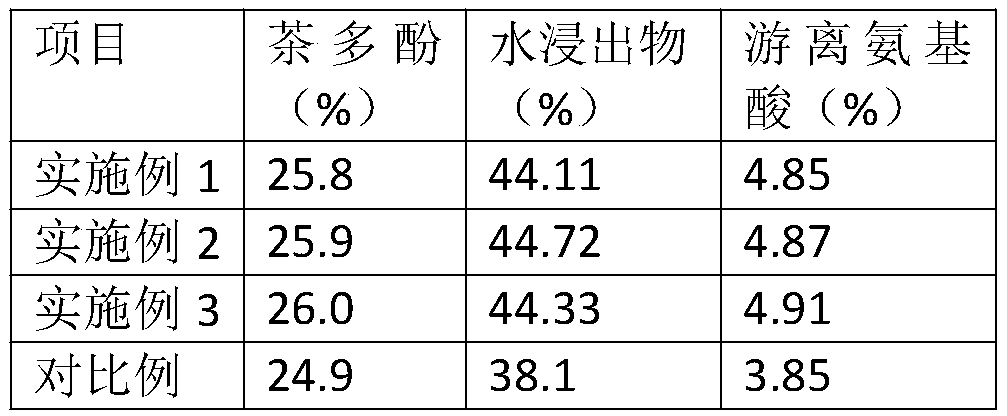

Embodiment 1

[0038] A processing method for high-fragrance tea, specifically comprising the following steps:

[0039] (1) Spreading and airing: picking fresh leaves with one bud and one leaf or one bud and two leaves from pollution-free or green tea gardens, using fresh leaves as raw materials, controlling the temperature of spreading and airing at 18°C and humidity ≤ 60%, according to the humidity of fresh leaves, old leaves The degree of tenderness is spread and aired for 6 hours; when the raw materials are spread to dry, avoid light, spread and air evenly, until the leaves begin to wither and have the fragrance of tea;

[0040] (2) Shaking green: according to the degree of tenderness of fresh leaves, use a tea shaker to control the low speed of 6rpm, shake green at low speed for 3 minutes each time, stop until the fresh leaves are about to appear red edges, and shake green again at low speed for 3 minutes after an interval of 1 hour, until Stop after the fresh leaves are about to appe...

Embodiment 2

[0050] A processing method for high-fragrance tea, specifically comprising the following steps:

[0051] (1) Spreading and airing: pick fresh leaves with one bud and one leaf or one bud and two leaves from pollution-free or green tea gardens, use fresh leaves as raw materials, control the room temperature of spreading and airing at 25°C, humidity ≤ 60%, according to the humidity of fresh leaves, old leaves The degree of tenderness is aired for 5 hours; when the raw materials are aired, they are protected from light, and aired evenly and ventilated until the leaves begin to wither and have a tea fragrance;

[0052] (2) Shake the green: according to the tenderness of the fresh leaves, use the tea shaker to control the low speed of 8rpm, shake the greens at a low speed for 3 minutes each time, stop when the fresh leaves are about to appear red edges, and shake the greens at a low speed for 3 minutes after an interval of 1 hour, until Stop after the fresh leaves are about to appea...

Embodiment 3

[0062] A processing method for high-fragrance tea, specifically comprising the following steps:

[0063] (1) Spreading and airing: picking fresh leaves with one bud and one leaf or one bud and two leaves from pollution-free or green tea gardens, using fresh leaves as raw materials, controlling the temperature of spreading and airing at 26°C and humidity ≤ 60%, according to the humidity of fresh leaves, aging The degree of tenderness should be aired for 4 hours; when the raw materials are aired, they should be protected from light, and aired evenly and ventilated until the leaves begin to wither and have a tea fragrance;

[0064] (2) Shaking green: according to the degree of tenderness of fresh leaves, use a tea shaker to control the low speed of 8rpm, shake green at low speed for 2 minutes each time, stop when the fresh leaves are about to appear red edges, and shake green again at low speed for 2 minutes after an interval of 1 hour, until Stop after the fresh leaves are about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com