A digital fabrication method of condylar fracture nail retention surgical guide

A production method and technology of fracture nails, which are applied in the fields of surgery and medical science, can solve the problems of high cost of use, low popularity of navigation systems, and impossibility of clinical application and promotion, so as to reduce implementation costs, reduce surgical risks, The effect of facilitating clinical application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

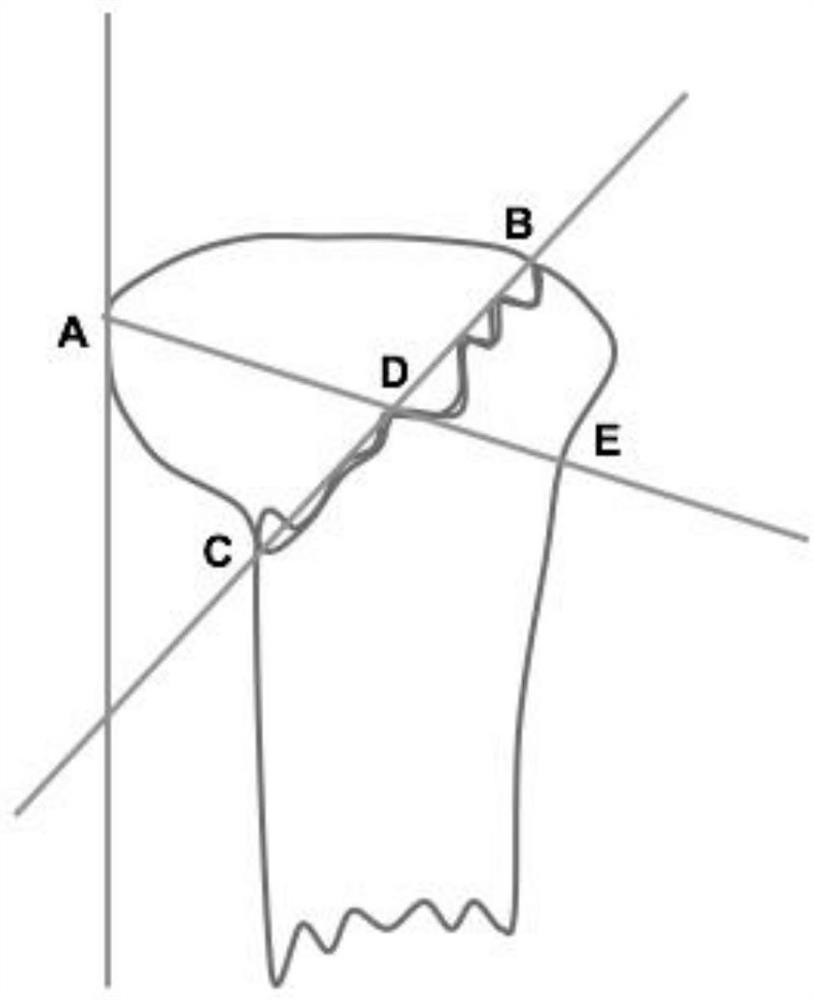

[0031] A digital manufacturing method of a condylar fracture screw fixation surgical guide, comprising the steps of:

[0032] Step 1: Scan the three-dimensional image of the patient's head through CBCT, the scanning parameters are 110kVp, 0.7mA, 3.6s, and obtain the DICOM data of the patient's maxillary and maxillary hard tissues;

[0033] Step 2: Use the open medical imaging software MIMICS to complete the condylar fracture virtual reduction surgery, anatomically reduce the free end of the fracture, and design the direction and depth of the retaining screw, specifically:

[0034] A. Input DICOM data into MIMICS software, and perform condyle free body and mandible modeling respectively through 3D reconstruction model;

[0035] B. Manually adjust the position of the free body until it is perfectly combined with the mandibular fracture, and further confirm the anatomical reduction in the coronal, axial and sagittal positions;

[0036] C. On the coronal position, select the laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com