Solid waste crushing device

A crushing device and technology for solid waste, applied in solid separation, magnetic separation, grain processing, etc., can solve the problems of dust re-pollution, complex crushing system, and high construction cost, and achieve high crushing efficiency, good flexibility, and reduced construction costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

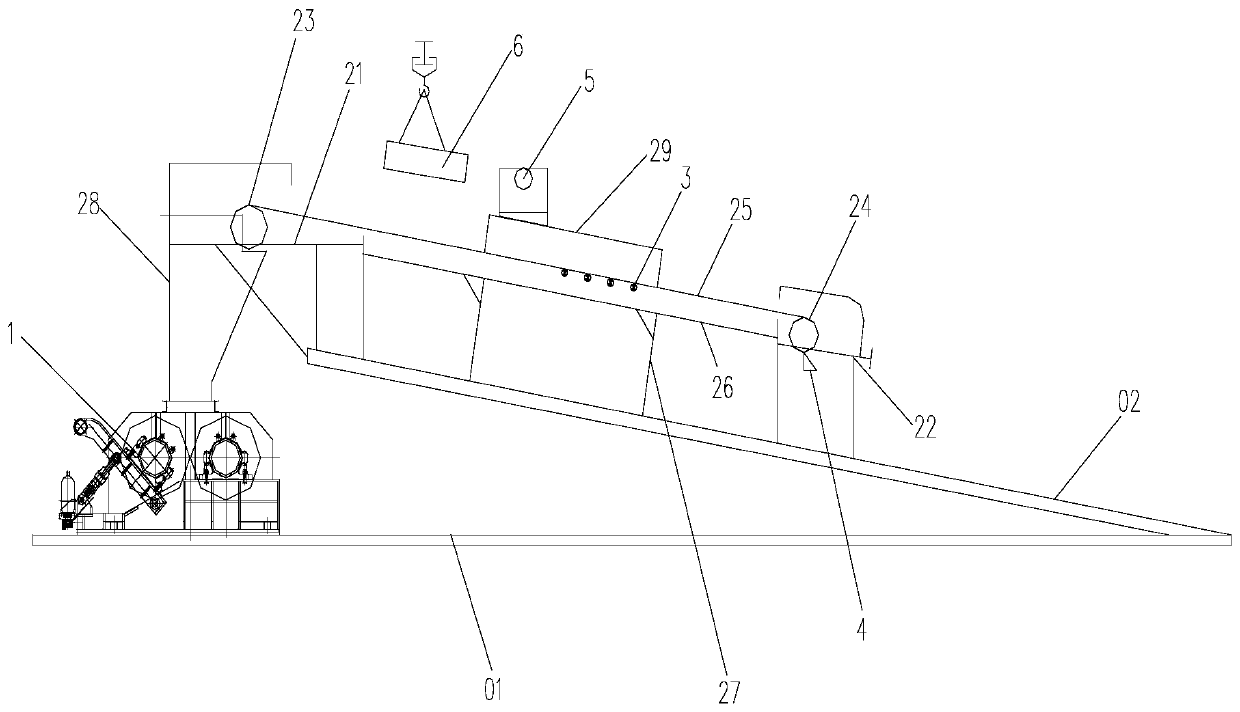

[0012] refer to figure 1 The embodiment of the present invention provides a solid waste crushing device, including a crusher 1, a conveying device, a horizontal platform 01, and an inclined platform 02. The crusher 1 is set on the horizontal platform 01, and the conveying device is set on the On the inclined platform 02, the inclined platform 02 forms an angle of 30° to 40° with the horizontal platform 01; Bracing frame 26, supporting leg 27, funnel 28, feeding trough 29, described head supporting frame 21 is arranged on the high end of described inclined platform 02, and described head...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap