Filter-paper dispensing line drying mechanism

A filter paper and glue dispensing technology, applied in the field of filters, can solve the problems of reduced filter paper life and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

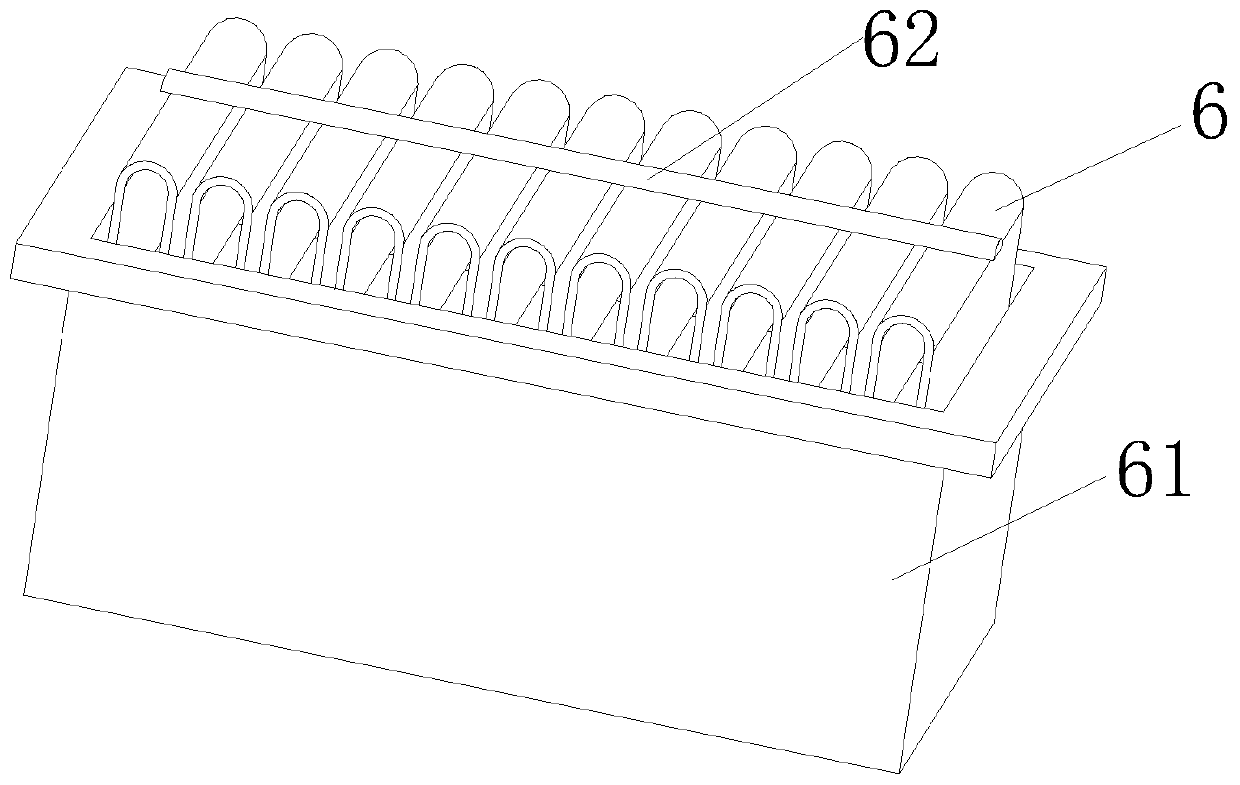

[0027] Such as image 3 As shown: the filter paper 6 targeted by the present invention is placed in a filter paper box 61 , and after the filter paper box 61 holds the filter paper 6 , glue is dispensed on the upper center of the filter paper 6 to form a glue strip 62 .

[0028] A drying mechanism for a filter paper dispensing line,

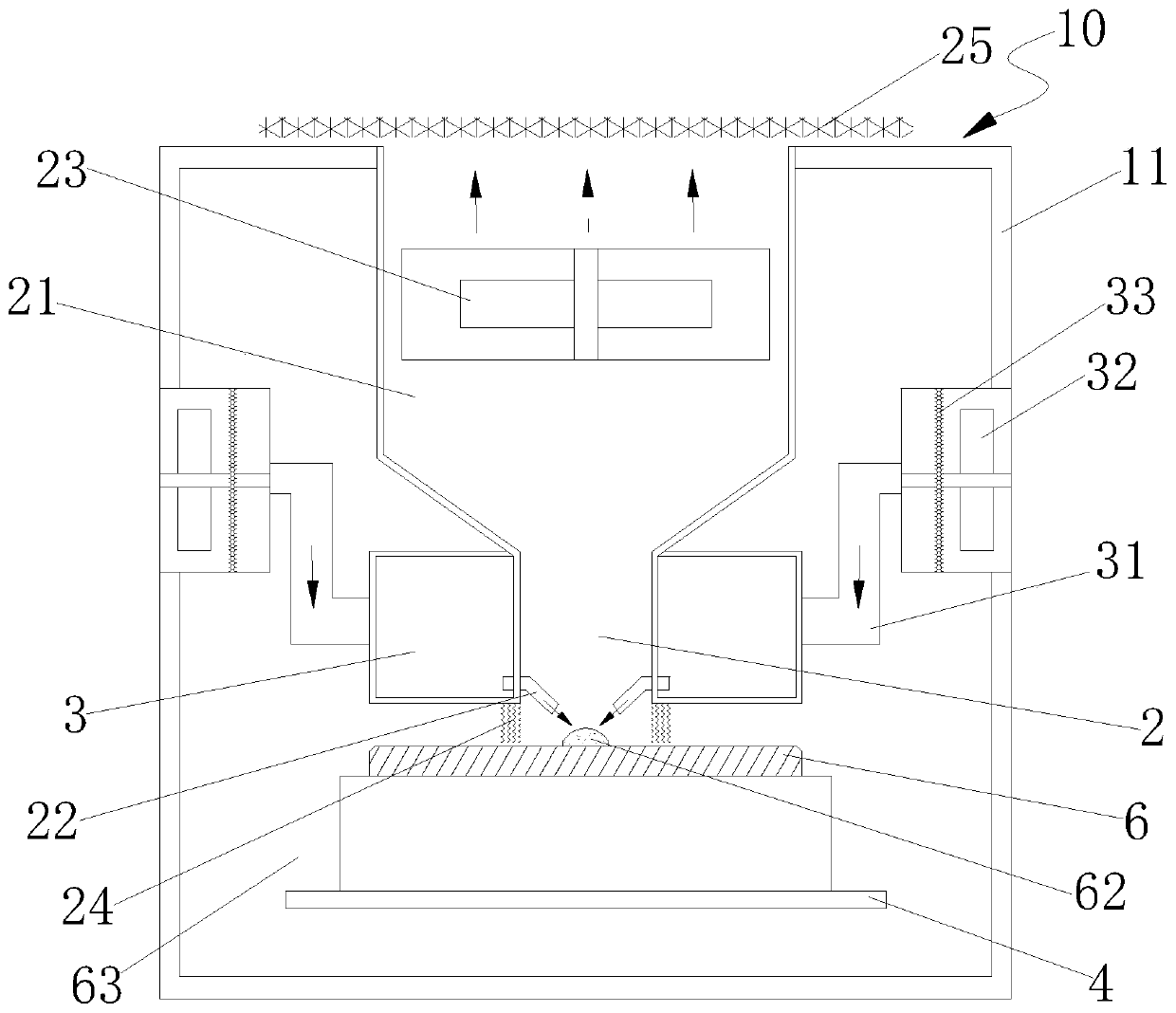

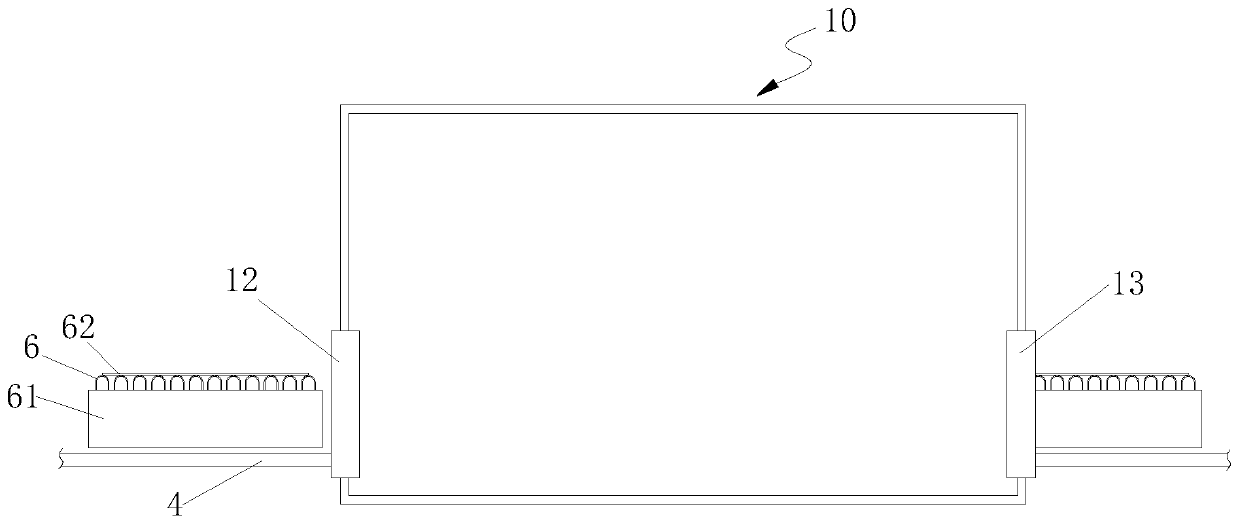

[0029] Such as figure 1 Shown: includes a drying device 10, the drying device 10 includes a housing 11;

[0030] The housing 11 is provided with a filter paper channel 63, an air suction channel 2 is provided directly above the filter paper channel 63, and an air intake channel 3 is provided on both sides of the air suction channel 2;

[0031] A suction cavity 21 is provided between the upper channel opening of the air suction channel 2 and the upper side wall of the housing 11, and the lower channel opening of the air suction channel 2 is facing the rubber strip 62 of the filter paper 61, and is in line with the The traveling direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com