Magnetostriction ultrasonic water jet structure

A magnetostrictive and giant magnetostrictive technology, applied in chemical instruments and methods, cleaning methods and utensils, metal processing, etc., can solve the problems of difficult high-speed water flow output, poor mobility, weak and popular applications, etc., to achieve easy installation The effect of disassembly, compact structure, and high magnetic-machine coupling characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred implementations of the present invention, and the scope of protection is not limited to this embodiment. All technical solutions under the idea of the present invention shall belong to the scope of protection of the present invention. At the same time, it should be pointed out that for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

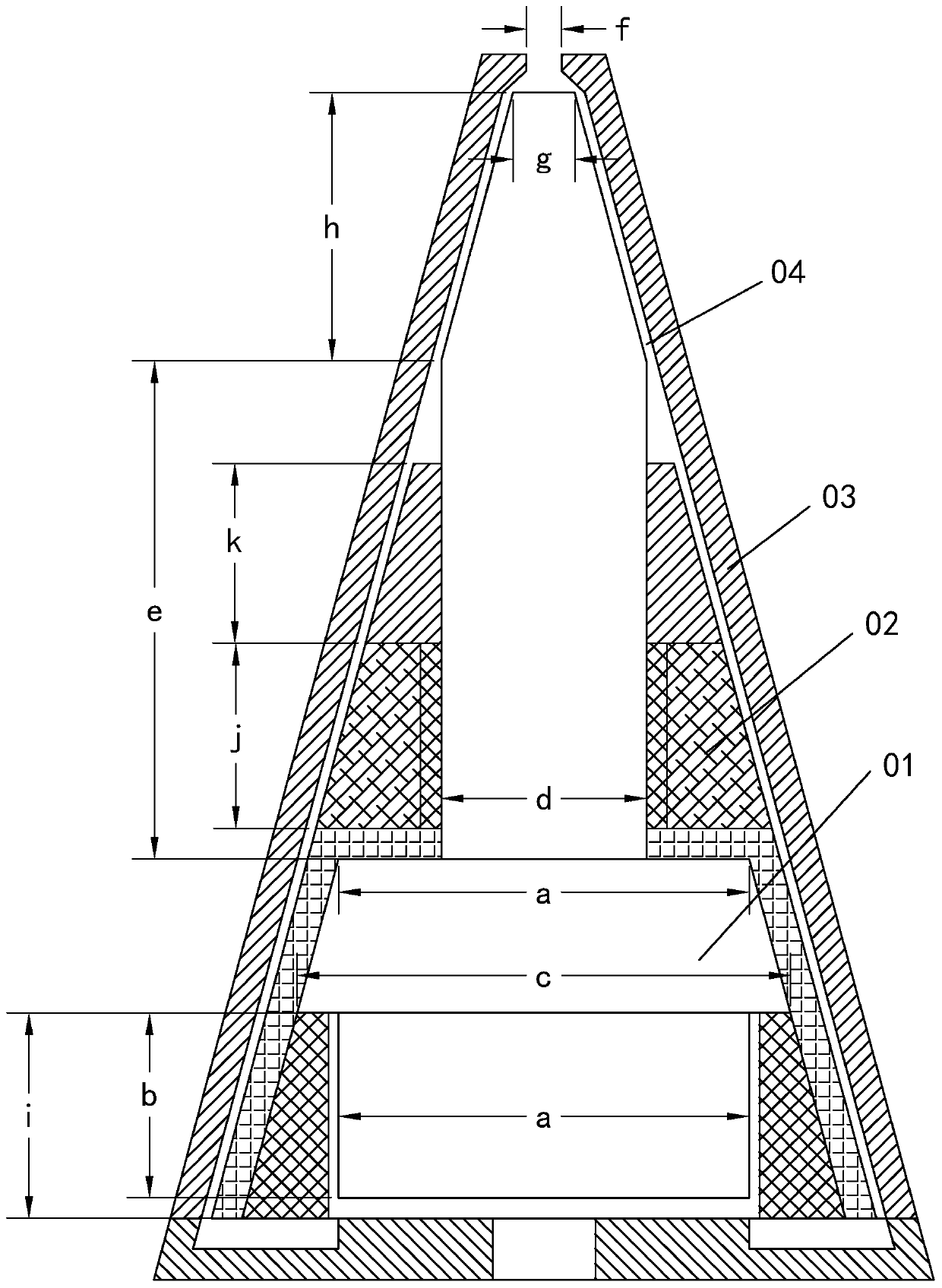

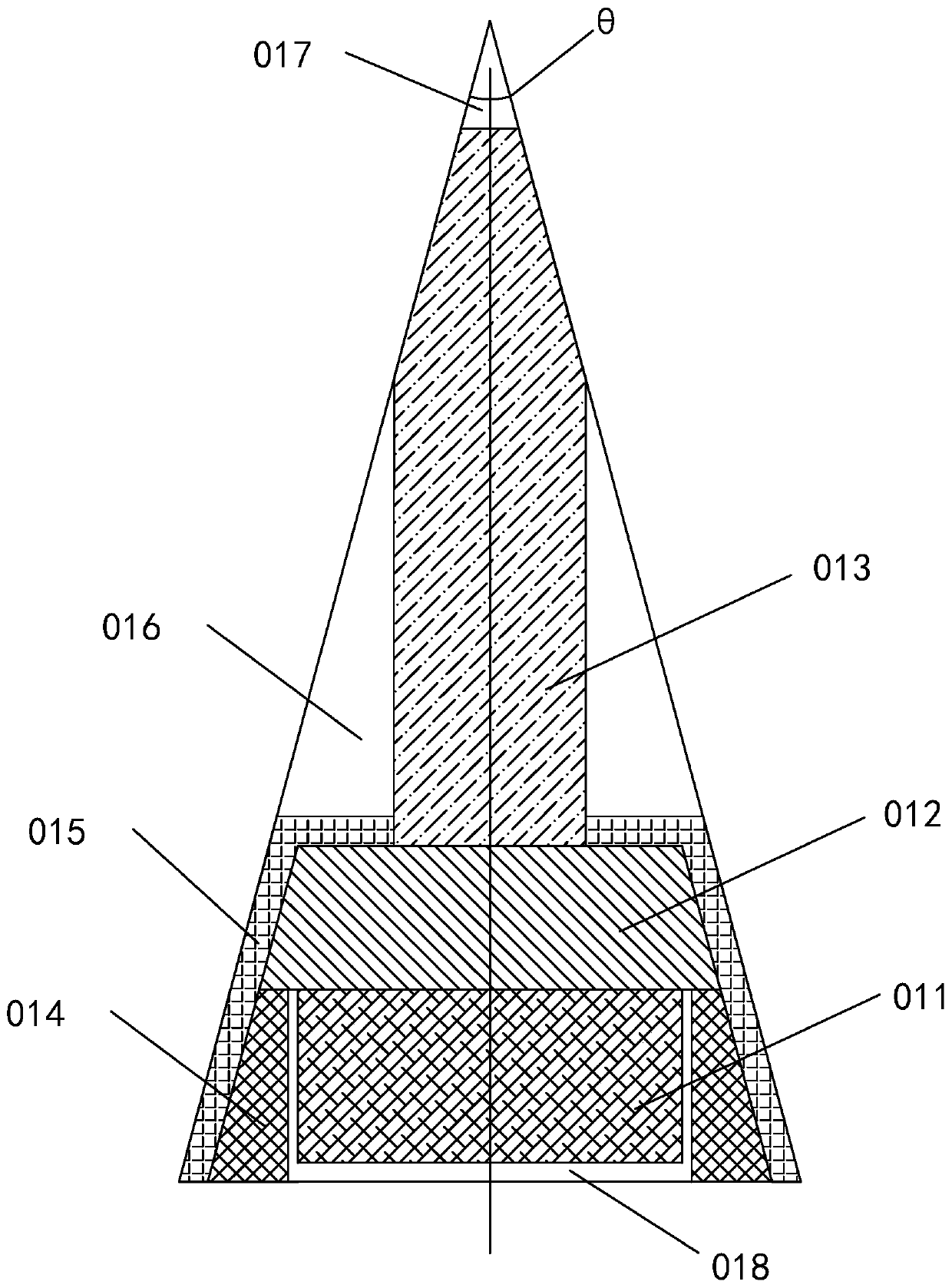

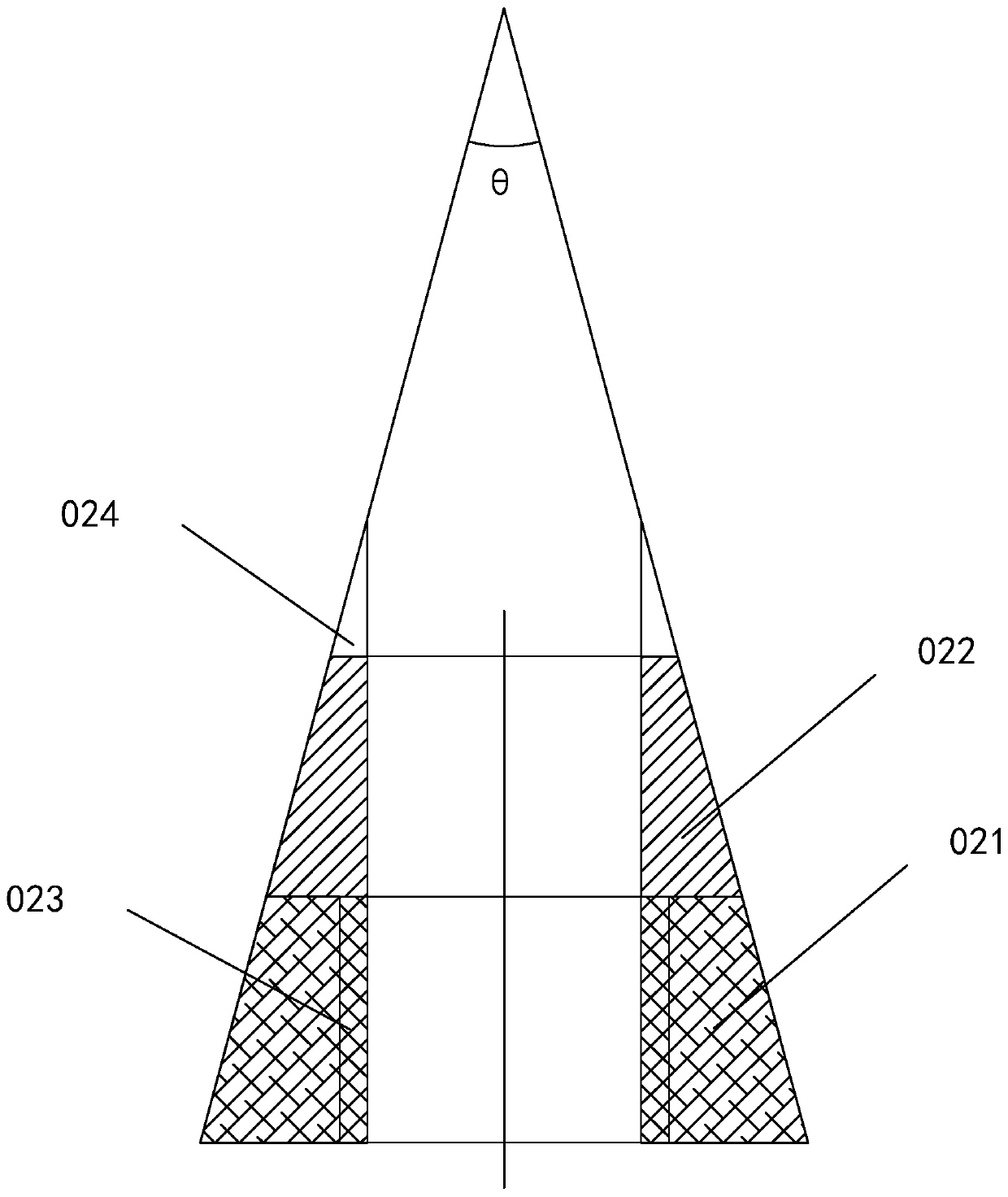

[0026] Such as Figure 1 to Figure 4 As shown, a magnetostrictive ultrasonic water jet structure includes a main ultrasonic drive part 01, an auxiliary ultrasonic drive part 02, a valve body part 03, and a flow channel 04, wherein the main ultrasonic drive part 01 and the auxiliary ultrasonic drive part 02 are placed on In the valve body part 03, the main ultrasonic driving part 01 is positioned and installed through the inner conical surface an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com