Efficient cleaning equipment of environment-friendly waste container

A technology for cleaning equipment and trash cans, which is applied to lighting and heating equipment, cleaning hollow objects, cleaning methods and utensils, etc. It can solve the problems of wet, unhygienic, and poor cleaning effects on the walls of trash cans, so as to improve environmental protection and environmental protection. Hygienic, prevent rapid contamination, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

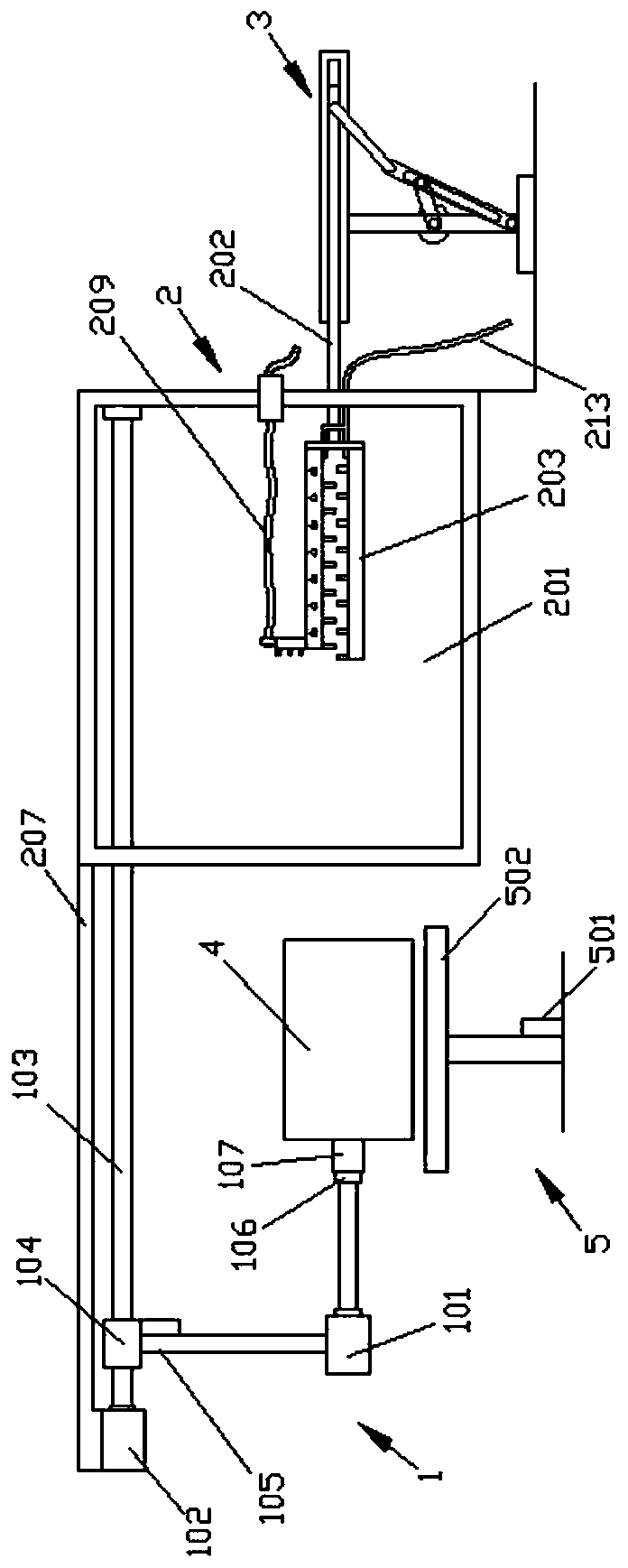

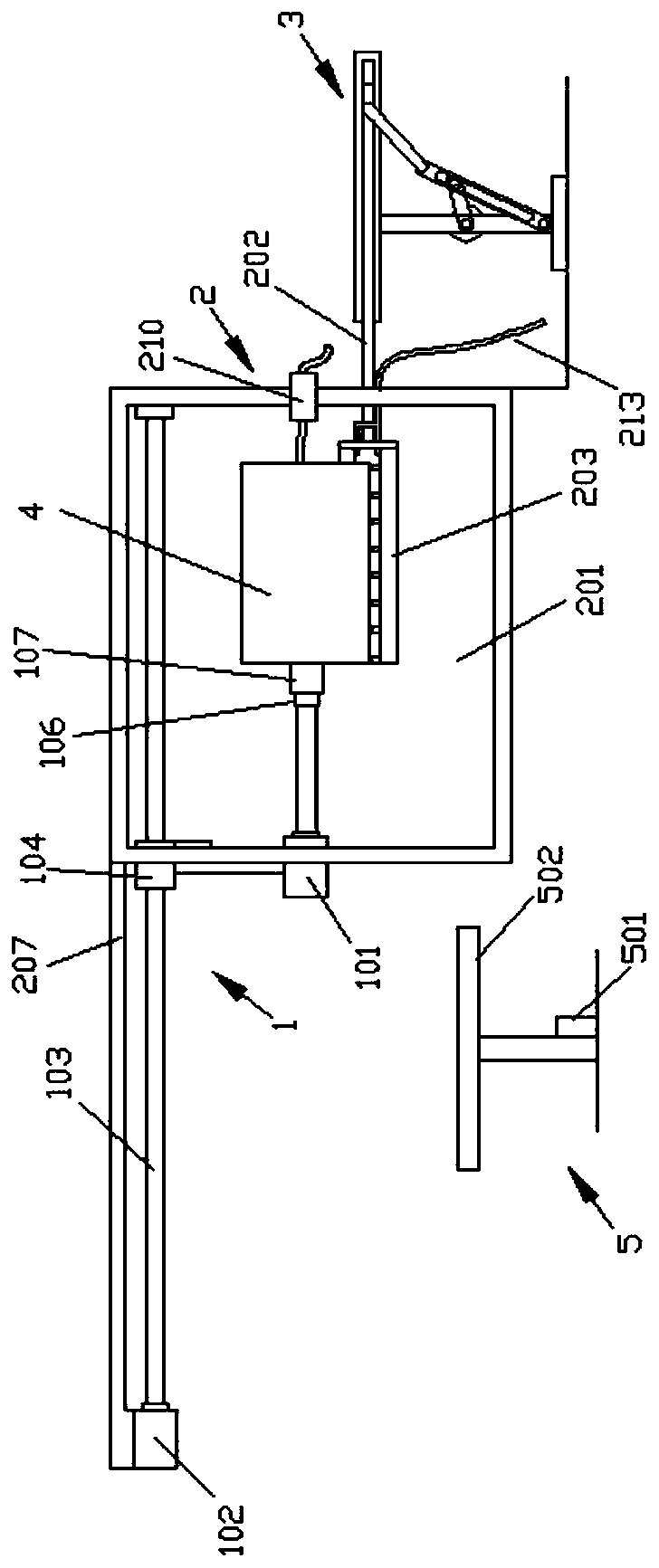

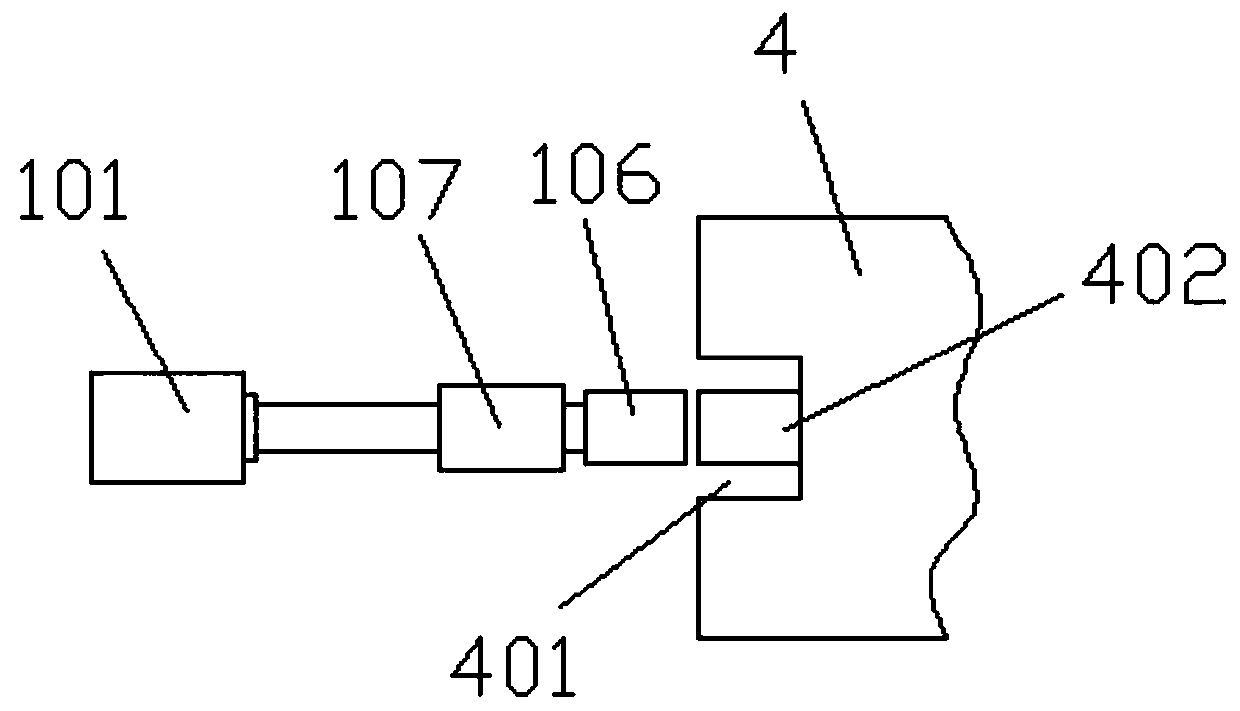

[0031] Such as Figure 1-Figure 4 As shown, a trash can is roughly cylindrical or cuboid in shape, including a cavity 401 located at the bottom of the barrel, and a first stud 402 is provided in the center of the cavity 401;

[0032] A device for cleaning the above-mentioned trash can, comprising a driving mechanism 1 and a cleaning device 2, the driving mechanism 1 includes a second stud 106 docked with the first stud 402, the second stud 106 is horizontally arranged, The left side of the second stud 106 is also provided with a first drive motor 101 and a connecting sleeve 107, and the inner wall of the connecting sleeve 107 is provided with an internal thread (not shown) that is matched with the first stud 402 and the second stud 106. Specifically, the power output end of the first driving motor 101 is connected to the left end of the second stud 106. When the connecting sleeve 107 is not in use, its state is set on the power output shaft of the first driving motor 101. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com