Thin-wall steel pipe clamping device

A technology of clamping device and thin-walled steel pipe, which is applied in the direction of auxiliary devices, tubular objects, applications, etc., can solve the problems of single operation and action mode of the clamp, and can not be assembled automatically, and achieve compact structure, high assembly efficiency, clamping reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

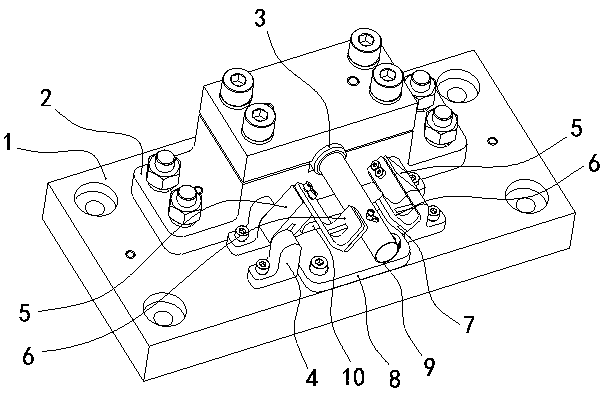

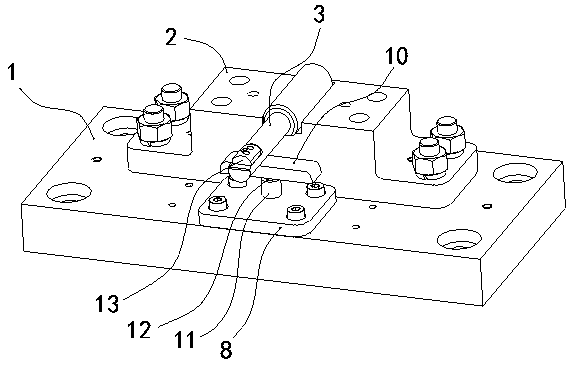

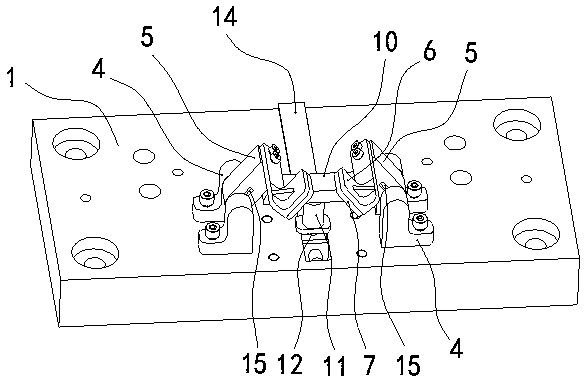

[0011] The specific embodiment of the thin-walled steel pipe clamping device of the present invention is as figure 1 , figure 2 , image 3 As shown, it includes a base 1, a mandrel 3 that is fixedly installed above the base 1 and extends forward and backward, and a clamping mechanism and a release mechanism that are installed on the base 1 and cooperate with the mandrel 3. The clamping mechanism includes 3 Two mounting seats 4 symmetrically arranged on the left and right sides of the axis, two connecting arms 5 mounted on the corresponding mounting seats 4 and two pressure plates 6 fixedly mounted on the corresponding connecting arms 5, the rotation axis of the connecting arms 5 and the plate surface of the pressure plate 6 They are all parallel to the axis of the mandrel 3, and between the two connecting arms 5 and the corresponding mounting seats 4 are respectively installed torsion springs 15 that drive the pressure plate 6 to be pressed against the surface of the mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com