Anti-skid and anti-rotation tubeless aviation wheel

A technology of anti-slip and wheel, applied in the direction of tire edges, rims, tire parts, etc., can solve the problems of wheel parts slipping, that is, sliding rotation, accident symptoms, affecting normal use, etc., to solve the problem of relative wheel sliding rotation problem, increasing the bonding contact area, and the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

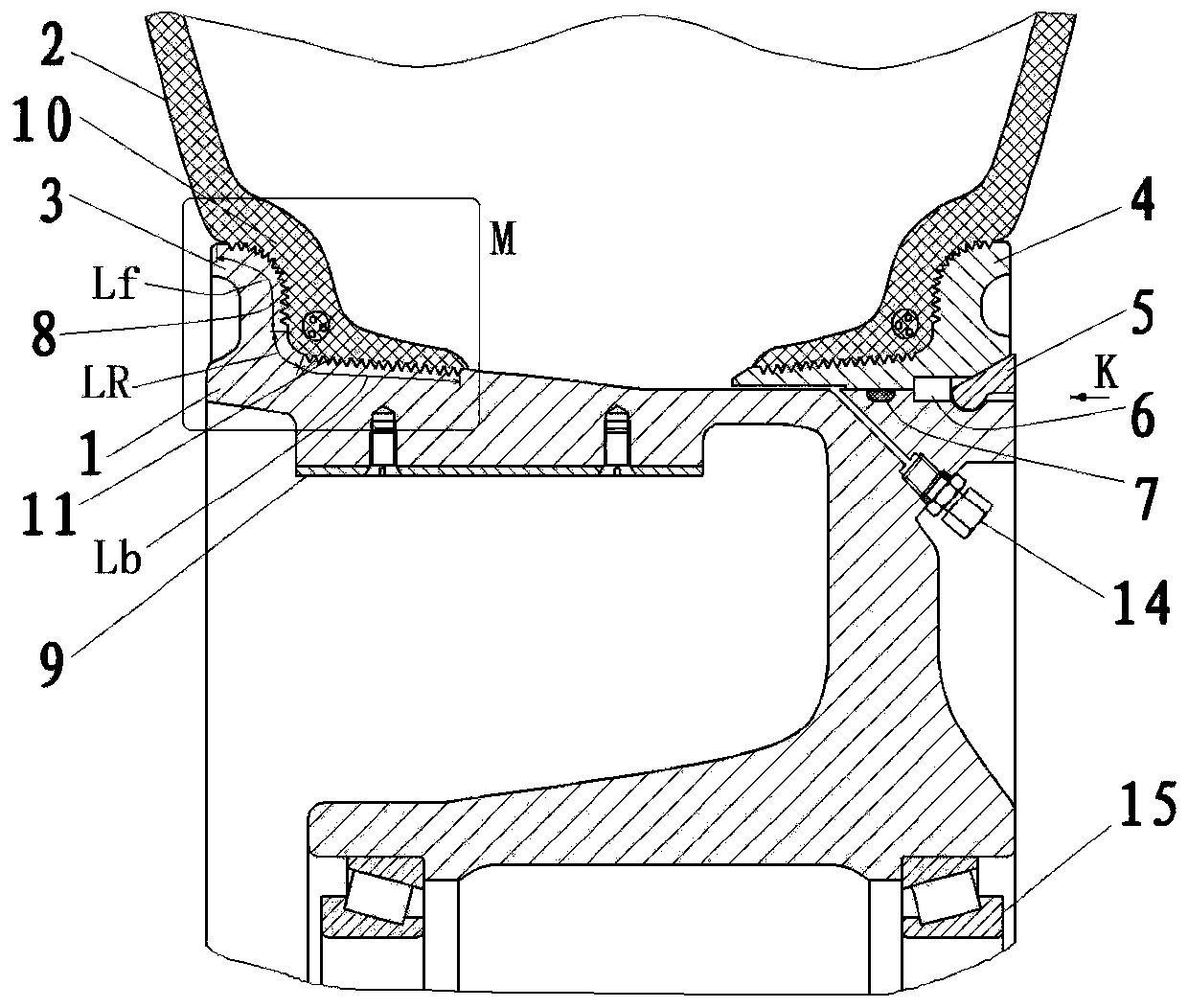

[0027] An anti-slip tubeless aircraft wheel, the anti-slip can prevent the wheel tire from sliding relative to the wheel and prevent the movable rim from sliding relative to the wheel hub.

[0028] The anti-slip tubeless aircraft wheel includes an aircraft wheel and a tubeless tire. Machine wheel is made up of machine wheel hub 1 and movable rim 4. The large end of the wheel hub 1 has a radially protruding fixed rim 3, and the small end of the wheel hub is equipped with a movable rim 4, and the movable rim 4 is installed in the outer circular snap ring groove of the small end of the wheel hub. The inner snap ring 5 is fixed. The airtightness of movable rim 4 and the mating surface of machine wheel hub 1 is guaranteed by the sealing ring 7 installed in the outer annular groove of the small end of the machine wheel hub.

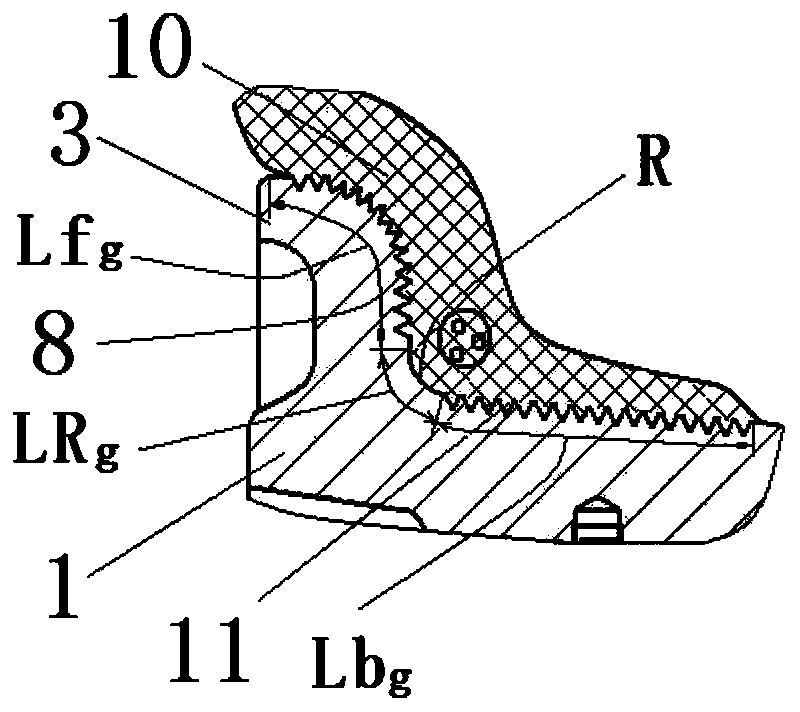

[0029] The tread 10 of the tubeless tire 2 includes a fixed rim tread and a movable rim tread. Wherein: the mating surface of the fixed wheel rim and the wh...

Embodiment 2

[0046] The present embodiment is an anti-slip tubeless aircraft wheel, including a wheel and a tubeless tire. The wheel includes a wheel hub 1 and a movable rim 4 .

[0047] The large end of the wheel hub 1 has a fixed rim 3 protruding radially; Ring 5 is fixed, and the airtightness of movable wheel rim 4 and machine wheel hub 1 mating surface is guaranteed by the sealing ring 7 that is installed in the outer annular groove of machine wheel hub small end.

[0048] The tread 10 of the tubeless tire 2 includes a fixed rim tread and a movable rim tread. Wherein: the mating surface of the fixed wheel rim and the wheel hub 1 is divided into three parts: the first part is the mating surface of the wheel hub profile, and the length of the mating surface of the wheel hub profile is Lb g . The second part is the arc area R at the root of the fixed rim g , the arc area R at the root of the fixed rim g The arc length is LR g . The third part is the mating surface of the fixed rim ...

Embodiment 3

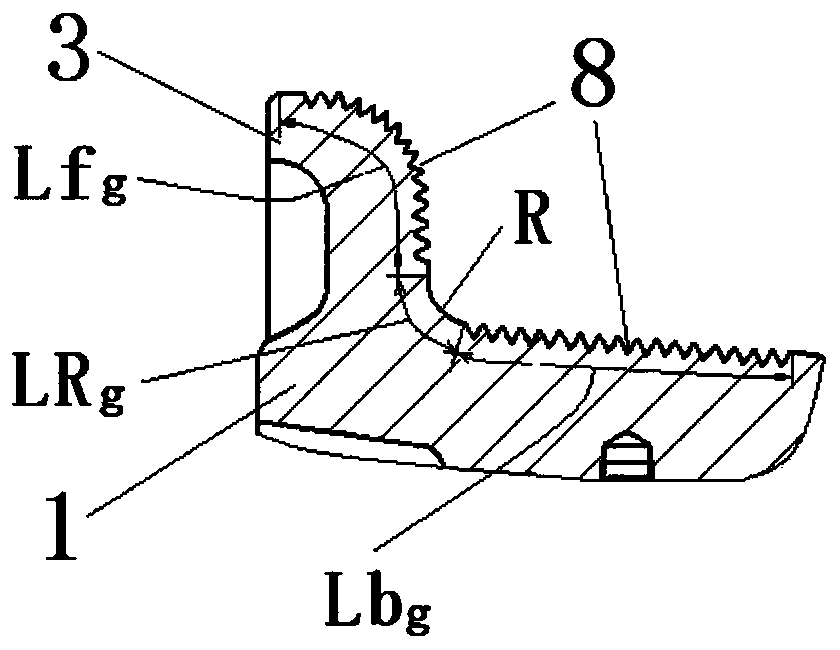

[0058] The difference between this embodiment and Embodiments 1 and 2 is that the surface where the tubeless tire cooperates with the fixed rim and the movable rim of the wheel hub does not have the ribs.

[0059] The present embodiment comprises machine wheel and tubeless tire; Machine wheel is made up of machine wheel hub 1 and movable rim 4. The large end of the wheel hub 1 has a radially protruding fixed rim 3, and the small end of the wheel hub is equipped with a movable rim 4, and the movable rim 4 is installed in the outer circular snap ring groove of the small end of the wheel hub. The inner snap ring 5 is fixed. The airtightness of movable rim 4 and the mating surface of machine wheel hub 1 is guaranteed by the sealing ring 7 installed in the outer annular groove of the small end of the machine wheel hub.

[0060] The mating surface between the fixed rim 3 of the wheel hub and the tubeless tire 2 is divided into three parts: the first part is the mating surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com