Compound plastic shell and preparation method and application thereof

A technology of composite plastics and manufacturing methods, applied in chemical instruments and methods, synthetic resin layered products, decorative arts, etc., can solve the problems of different thermal expansion coefficients, delamination cracking damage, small bonding area, etc., to improve service life, Improve the binding force and solve the effect of different thermal expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

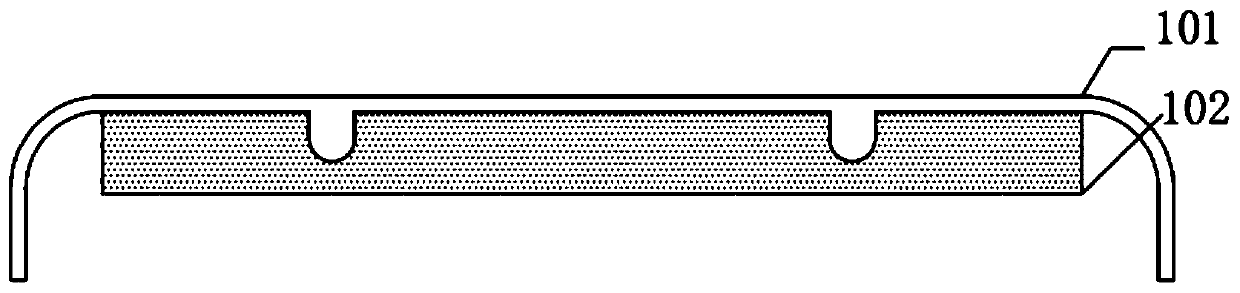

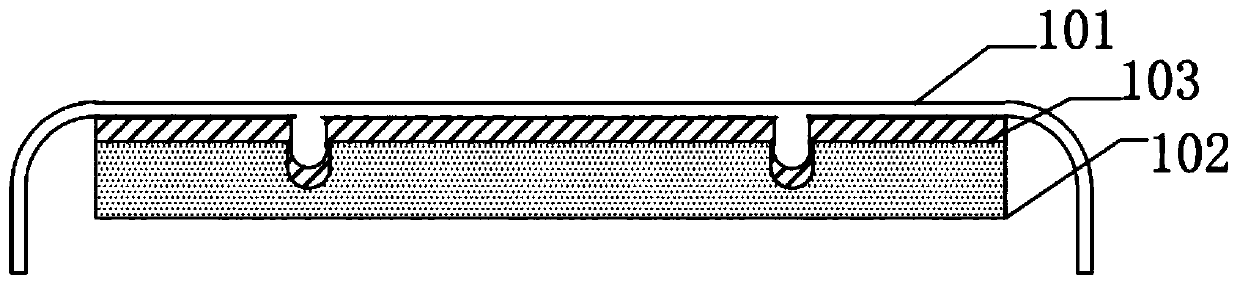

[0027] In another aspect, the invention provides a method for preparing a composite plastic shell, comprising the following steps:

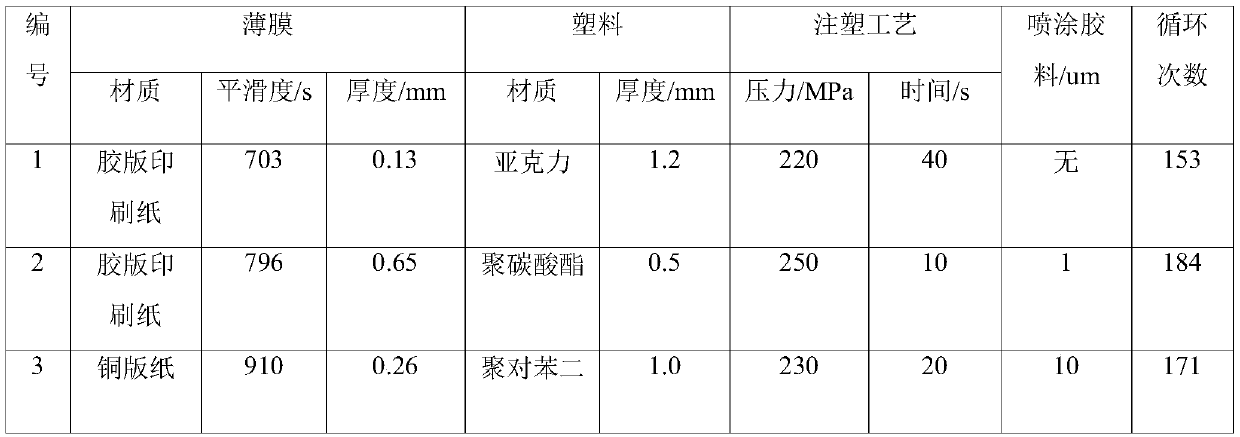

[0028] a) Put the fibrous structure paper layer into the mold cavity; the surface of the preferred fiber structure paper layer in this embodiment realizes the effect of surface decoration through prior art means such as ink printing and spraying, and the described fiber structure paper layer is a letterpress Printing paper, newsprint, offset printing paper, coated paper, book cover paper, dictionary paper, copy paper, cardboard and other fibrous papers with a hole structure on the surface, preferably offset printing paper and coated paper. Preferably, the surface smoothness of the fibrous structure paper layer is 700s to 1000s, and more preferably the surface smoothness is between 800s and 900s. If the surface smoothness is too low, the bonding force will be too strong, which will easily cause the paper to tear. Failure, and the ink printing effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com