Metal plate rolling compounding method, rolling forming composite plate and roller

A technology for rolling composite and metal sheets, applied in the directions of metal rolling, metal rolling, rolls, etc., can solve the problems of cracking, the connection and falling off of composite plates, etc., to improve rolling efficiency, not easy to separate, and increase the contact area of fitting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

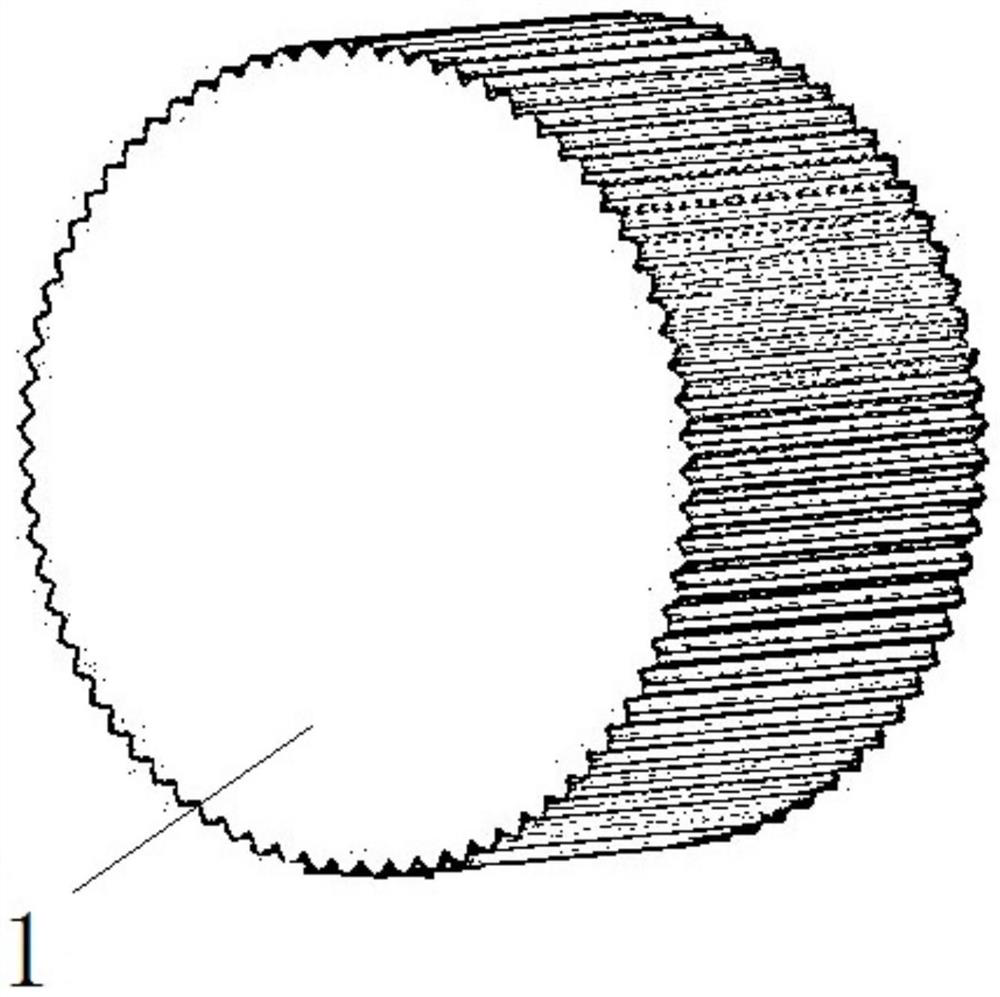

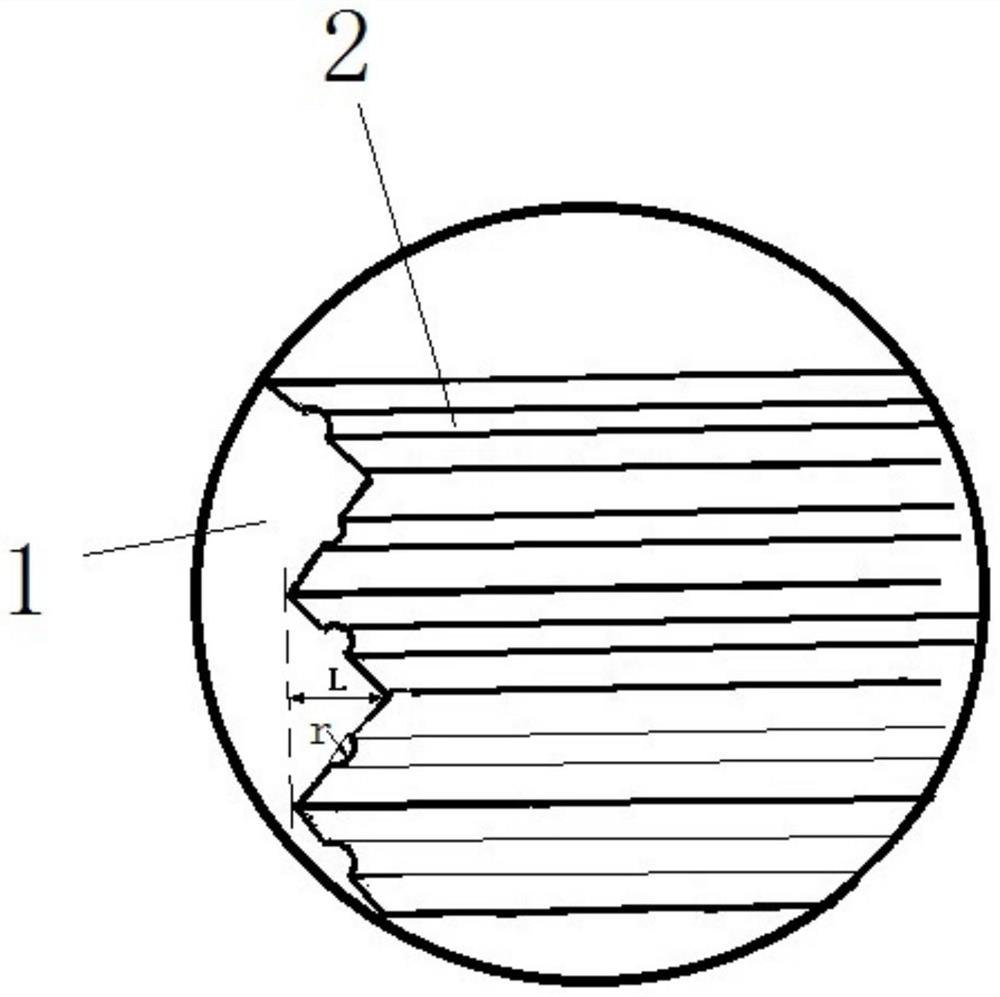

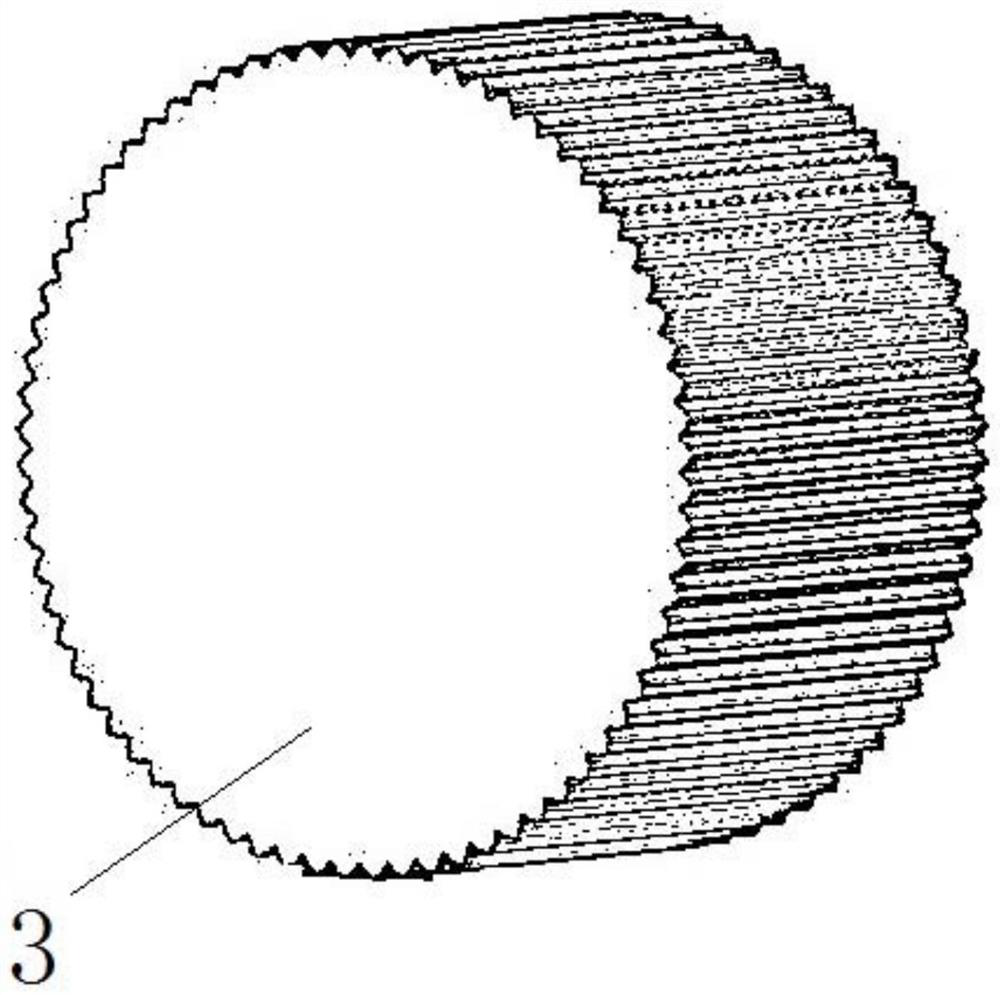

[0068] In this embodiment, the method of rolling and compositing the metal plate is completed by rolling the metal plate with rollers, such as figure 1 and image 3 As shown, the roll has a cylindrical cylindrical structure, the material of the roll is high-strength hard alloy steel with high performance requirements, and the roll is assembled on the rolling mill when in use. The roll includes a flat roll 11 with a flat outer peripheral surface and a corrugated roll with roll teeth on the outer peripheral surface. The roll teeth on the corrugated roll extend in the axial direction of the roll. After the rolled metal plate is in contact with the roll, with the rotation of the roll, the roll The teeth can roll a corrugated slope on the metal plate, and the flat roll 11 can roll a flat plane on the metal plate. Among them, the corrugated roll includes two different roll tooth structures, such as Figure 1 to Figure 10 As shown, one of the corrugated rollers is a raised corrugat...

specific Embodiment 2

[0078] The difference from Example 1 is that in Example 1, the two opposite slopes in the corrugated groove of the first corrugated surface 6 are formed with clamping grooves 9, and the two opposite corrugated edges on the second corrugated surface 8 are formed. Pre-card protrusions 10 are formed on the slope surface. In this embodiment, the number of roller protrusions on the grooved corrugated roller can be reduced, and the roller protrusions are arranged on the roller teeth at intervals, that is, the roller protrusions are arranged on the tooth surface every time a certain number of roller teeth are separated. The grooves on the first corrugated surface are separated by a certain number of corrugated edges. At this time, corresponding to the groove processing corrugated roller, the number of grooves on the convex processing corrugated roller is correspondingly reduced, and the grooves are arranged at intervals on the roller teeth. For every certain number of roller teeth, t...

specific Embodiment 3

[0080] The difference from Embodiment 1 is that in Embodiment 1, the clamping grooves 9 on two opposite slopes in the corrugated groove correspond one-to-one and the opposite slopes are symmetrically arranged. In this embodiment, the heights of the clamping grooves on the opposite slopes in the corrugated groove from the bottom of the corrugated groove are different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com