A thermal insulation system for building exterior walls and its construction method

A thermal insulation system and building exterior wall technology, applied in construction, thermal insulation, building components, etc., can solve problems such as hidden dangers of people and objects, cracking of the exterior wall matrix, hollowing, etc., to prevent bulging and falling off, and ensure bonding performance , Guarantee the effect of heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

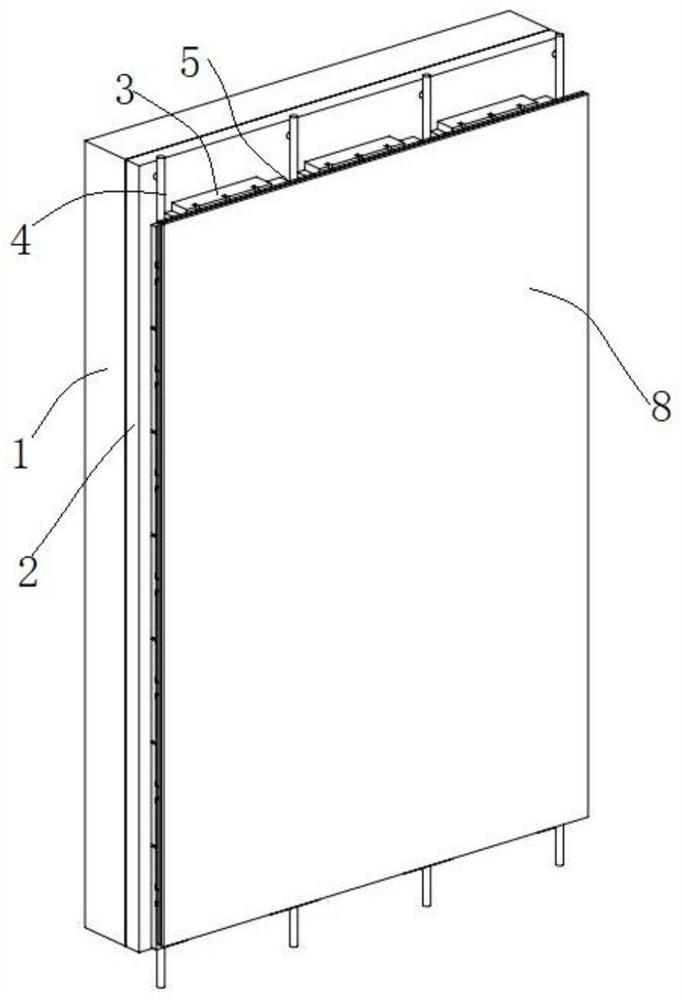

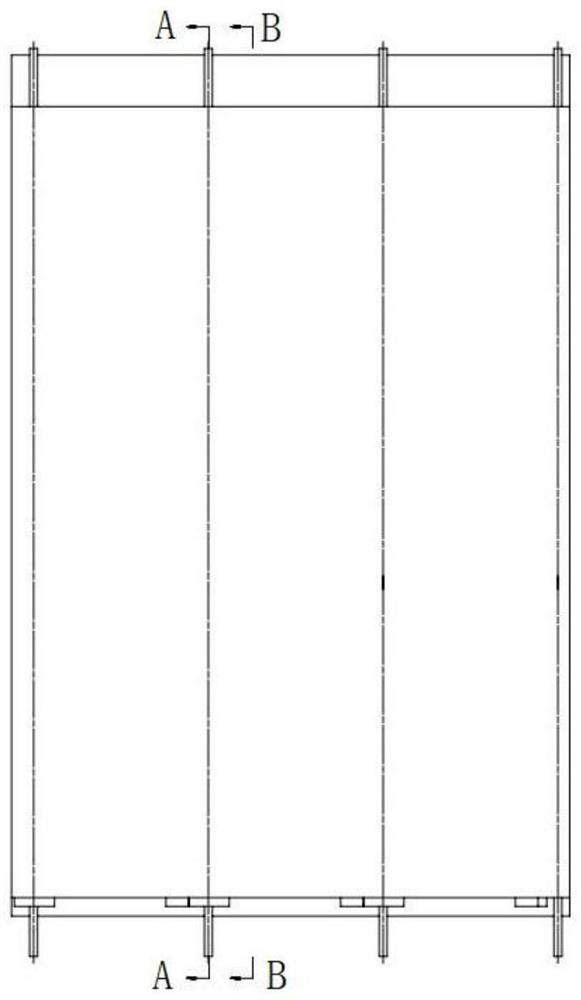

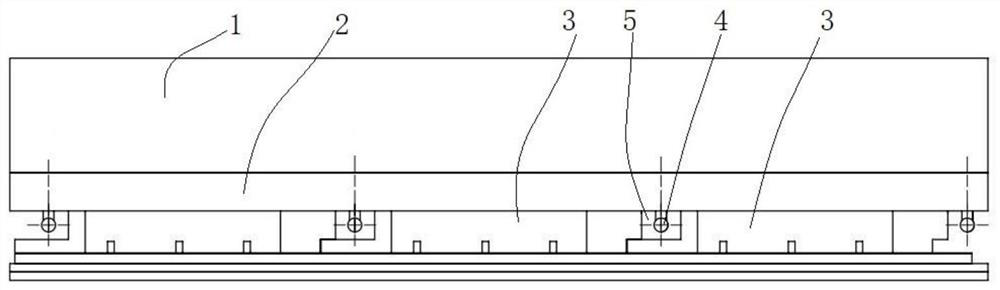

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

[0037] as attached figure 1 to attach image 3 As shown, a thermal insulation system for building exterior walls includes an exterior wall substrate 1, a mortar bonding layer 2, a thermal insulation board 3 and a pouring fixed substrate 4, and the thermal insulation board 3 is laid and bonded to the exterior wall through the mortar bonding layer 2. On the base 1, and a plurality of the thermal insulation boards 3 are arranged in a rectangular array, and the two adjacent thermal insulation boards 3 in the upper and lower directions are stacked directly or stacked by adhesive materials such as adhesives and mortar. Between the two adjacent thermal insulation boards 3 and the mortar bonding layer 2 in the horizontal direction, an annular pouring cavity 5 with only upper and lower openings and closed surroundings is formed, and the upper and lower sides of the pouring cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com